CSM Xplained Archive

Here you will find all past issues of CSM Xplained to watch and accompanying documents to download.

Measurement Technology The Vector CSM E-Mobility Measurement System Current and Voltage Power and Efficiency Temperature Durability Data Logging NVH

Measurement Technology

Safe measurement in high-voltage environments - Precise from sensor to data acquisition

Electric cars are now an integral part of road traffic - yet there is often still a lack of standardized measurement methods in their development. Comprehensive measurement of electric vehicles requires high-voltage-safe hardware solutions for almost all analog measured variables: In addition to measurement modules, this also includes sensor connection cables.

In this episode of CSM Xplained, we provide an overview of the applicable standards and specifications and present suitable measurement technology solutions together with our partner SAB Bröckskes.

Related Products

HV Isolation Testing Station

Operational safety test of high-voltage measurement modules

HV DTemp Measurement System

Digital measurement with up to 512 measurement points

HV Breakout Modules 1.2

Single-phase measurement of internal conductor current and voltage

HV Breakout Module 1.1

Single-phase measurement of internal conductor current and voltage

Maintenance of HV measurement technology – calibration and insulation testing

An essential aspect in long-term utilization of measurement technology is the regular calibration of the measurement amplifiers. In the case of high-voltage safe measurement technology, not only should the modules be part of a preventative maintenance and calibration schedule like other equipment, the high-voltage insulation test, which is urgently required according to EN 61010, must also carried out on a regular basis.

In this webinar, we will show you our solutions for calibration and HV insulation testing and deal with the following topics:

- How do you prevent measurement bottlenecks when calibration of your measurement amplifiers is due?

- How can you save valuable resources such as time, money and maintain confidence?

- What additional benefits do you enjoy by having your measurement technology tested at your site?

Related Products

HV Isolation Testing Station

Operational safety test of high-voltage measurement modules

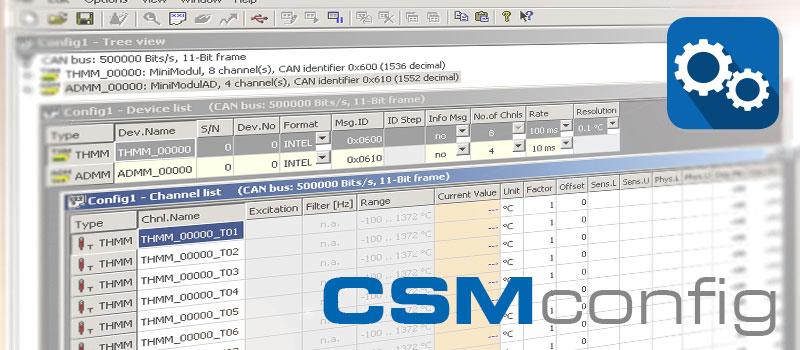

Configure measurement chains quickly and reliably - Avoid expensive and time-consuming errors

Increasing demands of developers on measurement tasks mean that the number of measurement channels is constantly growing and test setups are becoming more and more complex. Measurement chains with significantly more than 50 channels are no longer uncommon - and the error-free input of signal names and scaling factors can quickly become a challenge. For perfect measurement results, however, all designations must be correct. Typing errors and transposed numbers, made for example under time pressure, can render entire measurements unusable.

In this episode of CSM Xplained, we show how you can integrate existing data in just a few steps when configuring measurement chains and thus avoid costly errors.

This includes:

- Using standard names from signal databases

- TEDS as electrical data sheets

- Transferring calibration data from sensor databases

- Possibilities to split tasks and automate processes

Related Products

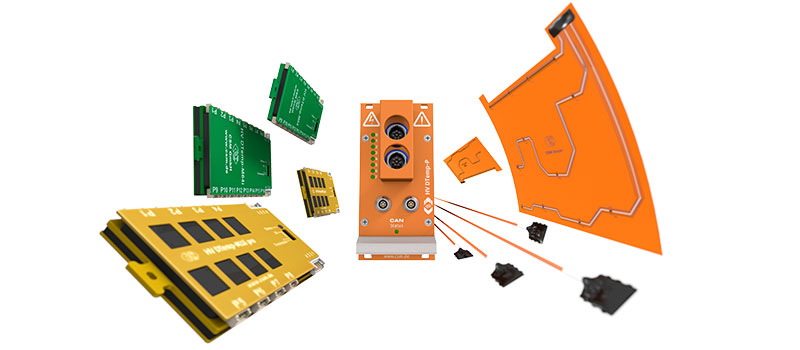

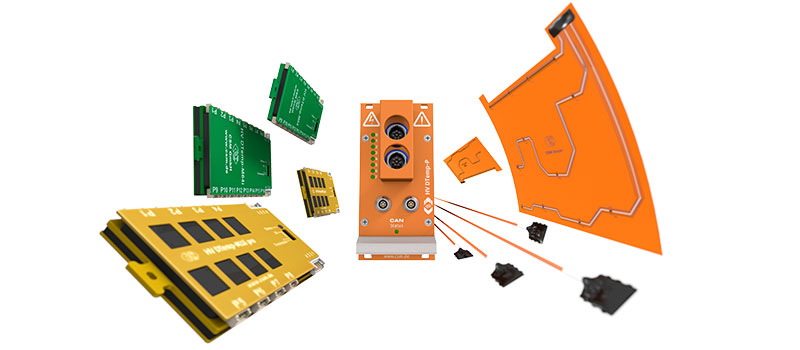

The Vector CSM E-Mobility Measurement System

Benchmarking in E-Mobility - Measurement Applications, Efficient Solutions

Benchmarking plays a major role in vehicle development. Vehicle manufacturers want to understand how competitors solve problems - service providers want to offer comprehensive and objective data sets that enable precisely these comparisons. To obtain this data and the resulting insights, robust and flexible measurement systems are required that can be used, for example, to implement a large number of measurement points for a wide range of measured variables in production vehicles in confined spaces.

In this web seminar, we will show you in a compact 25 minutes:

- What challenges benchmarking typically pose for measurement system.

- Which characteristics suitable measurement technology for low-voltage and high-voltage conditions should have for benchmarking.

- How CSM implements a wide variety of applications in practice.

Related Products

HV TH Measurement Modules

Safe temperature measurement with K-type thermocouples

CAN TH MiniModules

Temperature measurements with K-, J- and T-type thermocouples

HV Breakout Modules 1.2

Single-phase measurement of internal conductor current and voltage

The Vector CSM E-Mobility Measurement System

The measurement system for the development of electric mobility

HV Breakout Module 1.1

Single-phase measurement of internal conductor current and voltage

Efficient use of time and budget with modular measurement data acquisition

Global competition, time pressure due to shortened development cycles and rising costs in the areas of materials, energy and staff - these are the challenges currently facing the automotive industry. To overcome them, a flexible and cost-efficient measurement system is needed that provides vehicle manufacturers, suppliers and engineering service providers with a tool for vehicle development of electric and hybrid vehicles of all kinds.

In this web seminar you will learn:

- At which points in the measurement data processing are unnecessary time wasted and additional costs incurred.

- How to maximize the efficiency and availability of your measurement equipment.

- How to make even better economic use of test carriers.

Related Products

The Vector CSM E-Mobility Measurement System

The measurement system for the development of electric mobility

Measure accurately, analyse efficiently and manage professionally measurement results (of the electric powertrain)

vMDM (Vector Measurement Data Management) is the cloud solution for efficiently managing large amounts of data from development, test benches and drive tests.

A comprehensive function library, precise algorithms for calculating characteristic variables, and modern cloud technologies enable fast and meaningful analysis of the variables in electrical components, drives, and vehicle electrical systems that are precisely and time-synchronously recorded using CSM measurement technology.

Related Products

The Vector CSM E-Mobility Measurement System

The measurement system for the development of electric mobility

Testing of fuel cell drives on test benches and in road testing

Fuel cell drives require an extensive amount of testing and measurement during the development phase. This is because the combination of electrochemical components and power electronics places special requirements on the measurement technology.

In this webinar, we will take a close look at measurements on fuel cells and address the following questions:

- What tests are required on fuel cell drives?

- And what requirements result for the measurement technology?

- How can synchronous measurement data acquisition of chemical, physical and high-voltage electrical parameters be achieved on the test bench and in road tests?

Related Products

HV Breakout Modules

Measurement of internal conductor current and voltage as well as power measurement directly in HV cables

The Vector CSM E-Mobility Measurement System

The measurement system for the development of electric mobility

HV TH Measurement Modules

Safe temperature measurement with K-type thermocouples

CAN AD MiniModules

Allround measurement modules for sensors with analog voltage outputs

The Vector CSM E-Mobility Measurement System

For the comprehensive analysis and testing of electric vehicles, physical parameters from numerous sources (HV and low-voltage environment) must be acquired and analyzed. A precise evaluation of the data is only possible through the synchronous acquisition of the data. In addition, the design of such a measurement system should be conceivably simple and precisely tailored to the measurement task.

- How can various physical parameters (such as acceleration, strain, flow, humidity, and many more) measured with fast or slow signals and HV-safe or conventional?

- How can measurement data from additional sources, such as vehicle buses and ECUs, be integrated?

- How can the synchronicity of the measurements be ensured?

- What does an ideal measurement system for measurements on the test bench and in road tests look like?

Related Products

HV Breakout Modules 1.2

Single-phase measurement of internal conductor current and voltage

HV Breakout Module 3.1

Three-phase measurement of internal conductor current, voltage and instantaneous power

HV Breakout Module 1.1

Single-phase measurement of internal conductor current and voltage

The Vector CSM E-Mobility Measurement System

The measurement system for the development of electric mobility

Vector Smart Logger - The Intelligent Logging Solution for E-Mobility and ADAS Developments

When developing vehicle systems, engineers from development and validation often work on the same test vehicle. However, their working methods differ fundamentally. In development, the focus is on ad-hoc investigations with an interactive character. In validation on the other hand, preconfigured measurement jobs are recorded autonomously over several test drives. Up to now, different tools have been used: a computer-based measurement system and a specialized fleet logger. In practice, this always means set-up time - i.e. reconnecting when changing the mode of operation - and also doubled maintenance effort for the configurations.

Vector Smart Logger overcome these hurdles and offer a system that can be operated both interactively and autonomously. This significantly reduces setup time and configuration effort.

Beyond that, you benefit from a significantly higher range of functions compared to classic fleet loggers. Signals from vehicle ECUs and buses, radar, LIDAR, cameras, analog measurement technology as well as online calculations, e.g. of the eMobilityAnalyzer, can be recorded synchronously. Complex system interactions can be investigated holistically.

More information at www.vector.com

Find more videos about the Smart Logger in the Vector Youtube channel

Related Products

The Vector CSM E-Mobility Measurement System

The measurement system for the development of electric mobility

Use Cases

VIO System - Centralized measuring system with the additional something

Analog measuring systems can be classified into two groups: On the one hand, decentralized measuring systems that can be positioned in confined spaces and operated under demanding environmental conditions. On the other hand, centralized measuring systems, which are less robust and larger in comparison, but offer a higher number of measuring inputs and often lower costs per channel.

The new VIO system from Vector Informatik is such a centralized measuring system. Thanks to its measurement card-based design, the measurement system can be easily scaled. By integrating network interface cards, the measurement task can be extended from purely measuring analog measurement values to bus monitoring and adjustment.

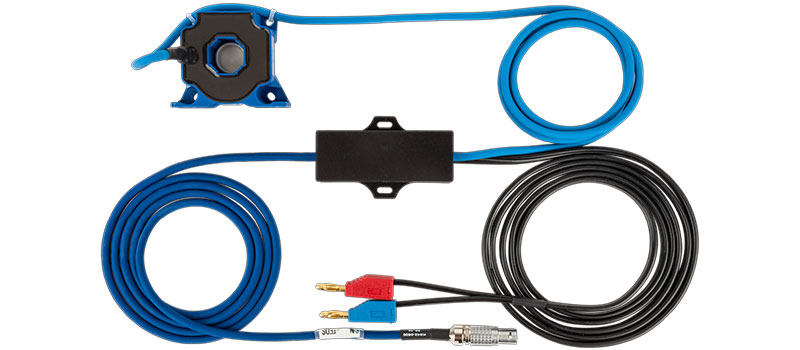

Current and Voltage

Current measurement in e-mobility

Currents must be measured at many points in the HV electrical system of modern electric vehicles: Be it to analyze charging and consumption processes or to verify protective measures against shield currents. The precise investigation of high-frequency current components requires a wide bandwidth in measurement, and instrumentation in particular can present users with challenges.

- Which currents must be measured at which points in the HV electrical system?

- What requirements are placed on the measurement technology?

- With which methods can currents be measured?

- How can current measurements be performed on test benches and in vehicle testing?

Related Products

HV Breakout Module 3.1

Three-phase measurement of internal conductor current, voltage and instantaneous power

HV Breakout Modules 1.2

Single-phase measurement of internal conductor current and voltage

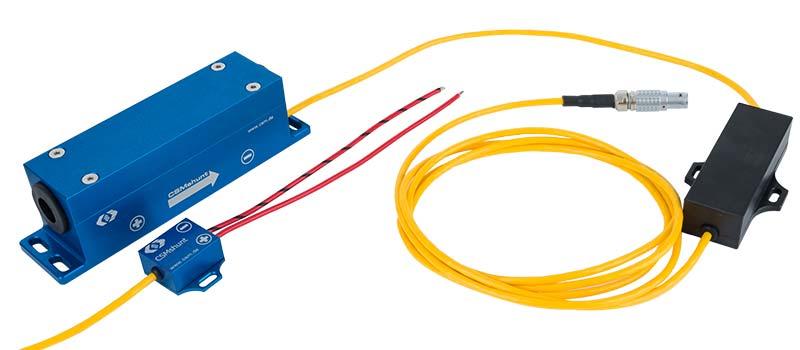

HV BM-Split evo

Measurement of voltage and current from the inner conductor in high-voltage (HV) electrical systems

AD4 ECAT MM Series

Easy measurement of fast analog signals

Voltage measurement in e-mobility

DC and AC voltages in the HV environment are characterized by peaks and dips as well as superpositions and have a significant influence on the interaction of all components. To ensure proper operation of the entire system, regulations set limits and must be verified.

- What are the typical characteristics and interactions of HV voltages in the vehicle electrical system?

- What must be considered when using measurement technology for voltage measurement?

- With which measuring instruments can HV voltages be reliably acquired?

- How can voltage measurements be performed in road tests and on the test bench?

Related Products

HV Breakout Modules 1.2

Single-phase measurement of internal conductor current and voltage

HV Breakout Module 3.1

Three-phase measurement of internal conductor current, voltage and instantaneous power

HV Breakout Module 1.1

Single-phase measurement of internal conductor current and voltage

AD4 ECAT MM Series

Easy measurement of fast analog signals

CAN AD MiniModules

Allround measurement modules for sensors with analog voltage outputs

Power and Efficiency

Autonomous power measurement in road tests and on test benches

The testing of electric drive systems requires a wide range of measurements and analyses of electrical power in the most varied degrees of detail. Depending on the application, extensive analyses including efficiency determinations may be necessary for the optimization of e-axles - while other contexts, such as the determination of consumption values, tend to benefit from independently performed power measurements.

Key points of the web seminar:

- What the different requirements are for power measurement and power analysis.

- When power measurements in combination with compact data loggers are advantageous in road tests.

- Why independent power measurements with black box systems can also be useful on the test bench.

- What advantages a modular, scalable and expandable measurement system offers.

Related Products

HV Breakout Modules

Measurement of internal conductor current and voltage as well as power measurement directly in HV cables

Temperature

Temperature measurement in e-mobility

Temperatures play a major role in the performance and safety of vehicles with electric, fuel cell or hybrid drive systems. If the temperatures in components such as the HV battery deviate significantly from their ideal range, performance losses, accelerated wear or even total failure are the result. Accordingly, temperatures must be measured intensively at many points.

- What is the significance of temperatures in electromobility?

- How can a HV-safe measurement chain be built - from the temperature measurement point to the data acquisition unit?

- What are the options for temperature measurement for the various applications?

- What advantages and disadvantages do the various options offer?

- How can hundreds of temperatures in HV batteries be measured efficiently and safely?

Related Products

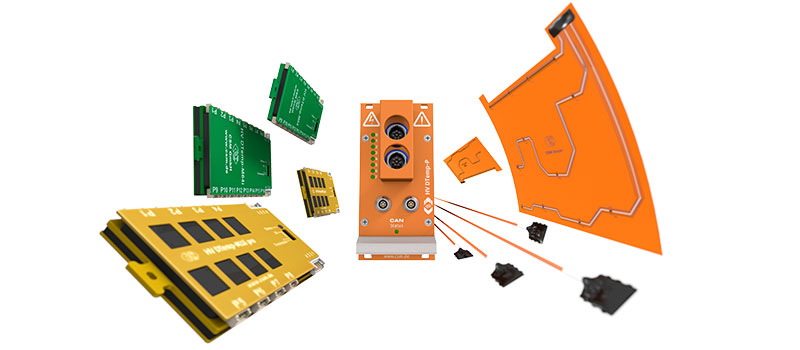

HV DTemp Measurement System

Digital measurement with up to 512 measurement points

HV PT Measurement Modules

Safe temperature measurement with PT100 and PT1000 sensors

HV TH Measurement Modules

Safe temperature measurement with K-type thermocouples

CAN TH MiniModules

Temperature measurements with K-, J- and T-type thermocouples

Thermal characterization of HV batteries

The performance, operational reliability, fast-charging capability and aging of HV batteries depend crucially on comprehensive and good thermal management. For this, it is important to know the temperature profiles within the battery that occur in different operating states in as much detail as possible. Battery management systems (BMS) have the task of operating the battery within its "comfort temperature".

The development of high-performance thermal management systems requires extensive thermal analyses.

- What is the significance of temperatures for the operation and safety of HV batteries?

- What has to be considered for temperature measurements in HV batteries?

- What special requirements does thermal characterization and validation of simulation models place on the measurement setup?

- How can hundreds of temperature measurement points be precisely acquired, even between battery cells?

Related Products

HV DTemp Measurement System

Digital measurement with up to 512 measurement points

Durability

Acceleration measurement in e-mobility

Accelerations must also be measured safely and precisely in high-voltage environments. For example, HV batteries are used as load-bearing elements in the vehicle frame. Accordingly, extensive investigations of fatigue strength are required on high-voltage components, but also within the HV environment.

- Where do accelerations need to be investigated within an electric vehicle?

- How can accelerations be measured HV safe for system and user?

- What challenges arise in acceleration measurement and how can they be solved?

Related Products

HV STG4 ECAT MM series

High-voltage safe measurement with strain gauges

Type HV STG4 pro BS20

AD4 ECAT MM Series

Fast measurement with IEPE sensors

CAN AD MiniModules

Allround measurement modules for sensors with analog voltage outputs

Durability measurement in e-mobility

Testing of durability poses great challenges for the measurement equipment to be used, especially in the high-voltage environment. For example, the so-called "swelling" is to be investigated on HV battery cells. For this purpose, strain gauges are primarily used whose output signals, some of which are very small, must be recorded precisely, reliably and safely at a high voltage potential.

- Which critical points in the electric vehicle typically have to be examined for their durability?

- How can the signals of bridge-based sensors such as strain gauges be acquired in a HV-safe manner?

- What challenges arise in particular with strain gauge measurements at HV potential and how can they be solved?

Related Products

HV STG4 ECAT MM series

High-voltage safe measurement with strain gauges

Type HV STG4 pro BS20

STG6 ECAT MM-Series

Fast distributed strain gauge measurements

Type STG6 pro BS20 | STG6 BK20

Whether rotating or static - Safe acquisition of strains and temperatures in e-mobility

The reliable detection of strains and temperatures in the e-mobility environment poses a major challenge - the very small amplitudes of the measurement signals are many orders of magnitude below those of the system voltages of several hundred volts used. And the wireless transmission of these measured variables is also massively hampered by the enormous electromagnetic interference generated by respective components of electric vehicles themselves.

In this episode of CSM Xplained, we present exciting solutions for the reliable and precise measurement of strain gages and temperatures. Find out more about high-voltage safe, wired and also innovative wireless solutions for strain gages and temperatures - this time in interview format with telemetry expert Gerhard Spitz from AXON Systems.

Related Products

HV STG4 ECAT MM series

High-voltage safe measurement with strain gauges

Type HV STG4 pro BS20

STG6 ECAT MM-Series

Fast distributed strain gauge measurements

Type STG6 pro BS20 | STG6 BK20

Data Logging

Bye Bye Measurement Computer – Efficient and Intelligent Logger Solutions for Road Testing

The use of classic measurement computers in supervised test driving is problematic in many respects. Staff supervision costs, occupant safety during extreme driving maneuvers and operability under driving conditions are just some of the disadvantages of using laptops and other display-supported end devices. In this episode of CSM Xplained, we show how the measurement computer can be dispensed with in many applications and replaced by a robust and connected data logger.

In this web seminar, we will show you in compact 30 minutes:

- What problems and risks can the use of measurement computers in road tests entail?

- How can intelligent data logger solutions leave the supervised measurement computer unnecessary in road tests?

- Which tools and features can connected data loggers use to compensate for relevant functions of the measurement computer?

Related Products

UniCAN 3 ETH Data Logger

Data logger for mobile applications with Ethernet interface

Data logging of analog signals in worldwide fleet testing

The electrification of mobility in particular has intensified competition among vehicle manufacturers. At the same time, the amount of data generated in modern vehicles is exploding as a result of progressive digitization. Extensive recording of fieldbus data, e.g. from control units by means of powerful data loggers, is becoming increasingly important.

To remain competitive, field tests and fleet tests must be as reliable and efficient as possible. For this purpose, worldwide data transmission of the recorded measurement data by means of modern wireless technologies is essential. In addition, it must be possible to manage large vehicle fleets easily and conveniently.

Learn how to meet these challenges in this issue of CSM Xplained.

Related Products

UniCAN 3 ETH Data Logger

Data logger for mobile applications with Ethernet interface

Aspects of security in data logging

When recording measurement data in fleet testing, the security of your data plays an essential role. An overall system that works reliably and at the same time protects data sources and recordings from unauthorized access, is required. In this episode of Xplained, we show you how this can be implemented with our system.

Key points of the web seminar:

- How can you ensure that measurement recording is performed reliably and correctly?

- To what extent is your recorded data safe from "data theft"?

- How is your measurement data transmitted completely, error-free and tap-proof?

Related Products

UniCAN 3 ETH Data Logger

Data logger for mobile applications with Ethernet interface

NVH

High-voltage- and NVH-Measurements in Electric Vehicles

The electrification of the vehicle powertrain poses major challenges for the interaction of the individual components. In order to optimize both - the acoustics and the performance of electric vehicles, high-voltage and NVH measurement data must be acquired synchronously.

In this web seminar we show the problem in the acoustics of electric vehicles and the solutions for eMobility and NVH analysis:

- Challenges in electric vehicle acoustics

- Synchronous acquisition of NVH and power data on the powertrain

- Correlation of NVH and power analyses

Related Products

HV Breakout Modules 1.2

Single-phase measurement of internal conductor current and voltage

Home

Home