Fuel Cell-electric Drive Functional Test

Fuel cell-powered vehicles are a complement to pure battery electric-powered vehicles in electromobility. An electrochemical reactor is used to generate electrical energy that is available for the drive and other vehicle systems. The interaction of this reactor in the fuel cell stack with the other components in the powertrain is tested on test benches. In this example, you will learn how the necessary measurements are carried out simply and synchronously.

Background

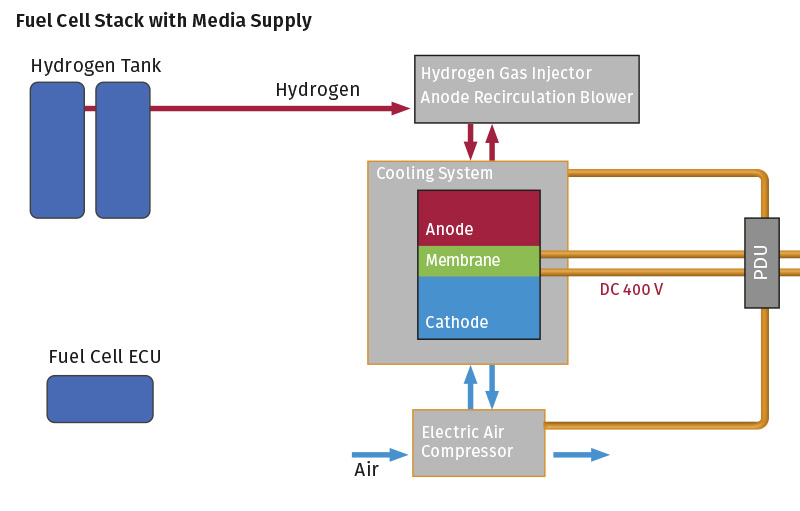

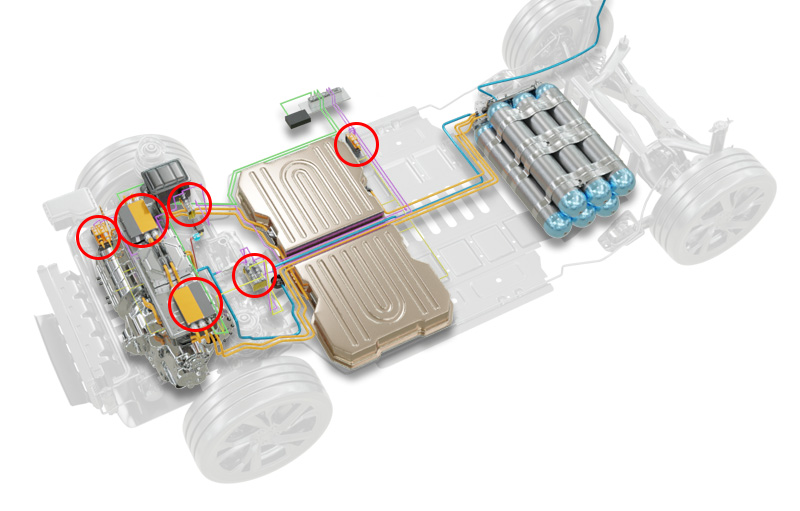

Numerous fuel cells connected in series are combined in the fuel cell stack. In a so-called "cold combustion", electrical energy is generated in these cells from hydrogen and atmospheric oxygen. In order to control this process, the supply of hydrogen and atmospheric oxygen must be precisely regulated and the entire fuel cell stack must be kept within a defined temperature range.

The fuel cell-electric drive is usually a complete component of a vehicle provided by a supplier. In combination with the other components of the vehicle powertrain, the result is the overall vehicle performance and dynamics. The characteristics, functions and properties of the fuel cell-electric drive are verified on test benches up to production release with various tests. To do this, current, voltage and power, as well as other measured variables such as temperatures, flow rates, pressures and humidity, must be acquired at various points in the fuel cell stack and powertrain.

Measurement task

Acquisition of current, voltage and power as well as other measured variables to test characteristics, functions and properties of the fuel cell drive.

Challenge

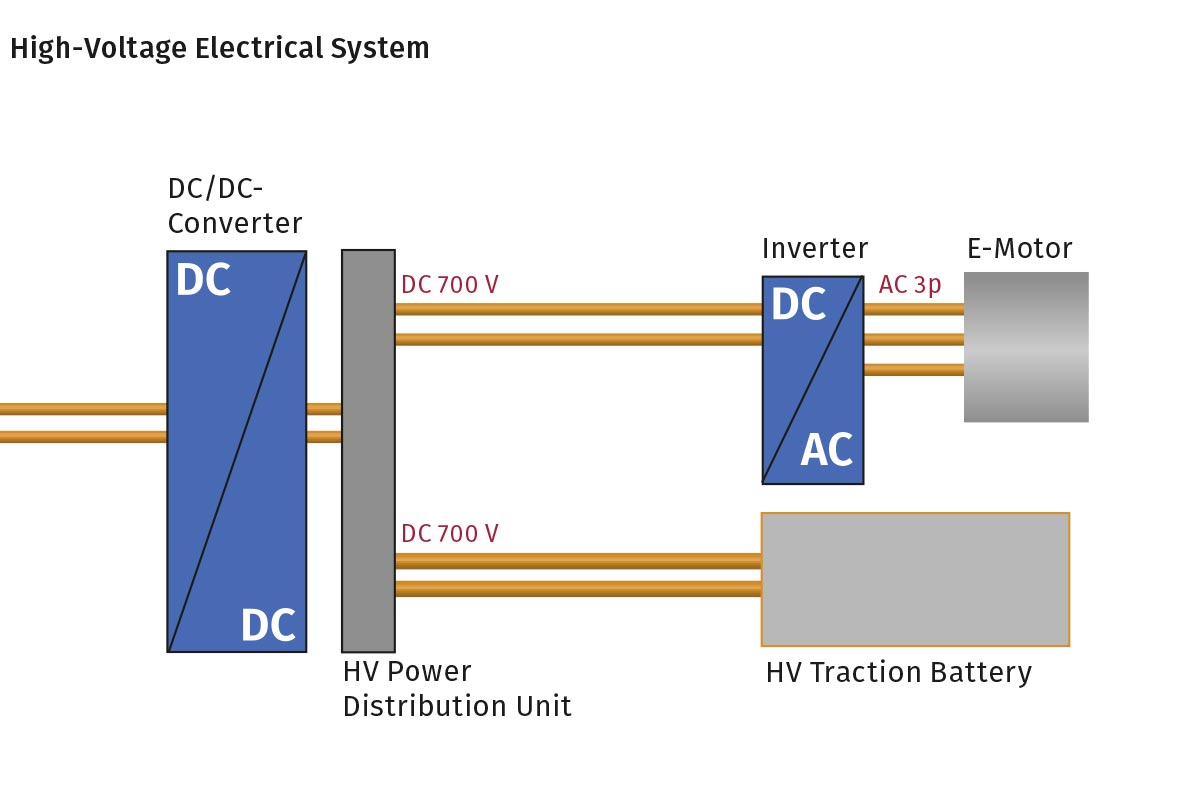

The functional tests cover all operating functions such as cooling circuit, cooling control, heating, hydrogen paths (anode path), air paths (cathode path), high-voltage electrical paths, sensor technology and fuel cell control unit. High-precision measurement of a wide range of physical parameters is required for functional testing and validation of the fuel cell drive system. In addition to temperatures, volumetric flows, humidity and pressures, high-voltage measurements of currents and voltages in the high-voltage circuits are necessary. From these, the delivered energy, power and efficiency are calculated.

With validation, the system requirements such as performance parameters, reaction speed to load changes or service life are proven with tests and endurance runs.

to check correct operation in the various operating phases. For example, the characteristic curve of the power during the warm-up phase, for start-up, load changes, partial load and peak load as well as various other distinctive operating points.

Ultimately, the specified efficiency curves of the fuel cell-electric drive are demonstrated. The efficiency is the energy delivered in relation to the hydrogen consumed. It depends on the load point and the optimal supply of the different media: hydrogen, atmospheric oxygen, humidity and cooling. A non-optimal supply, for example of stack humidification, leads to a drop in stack voltage.

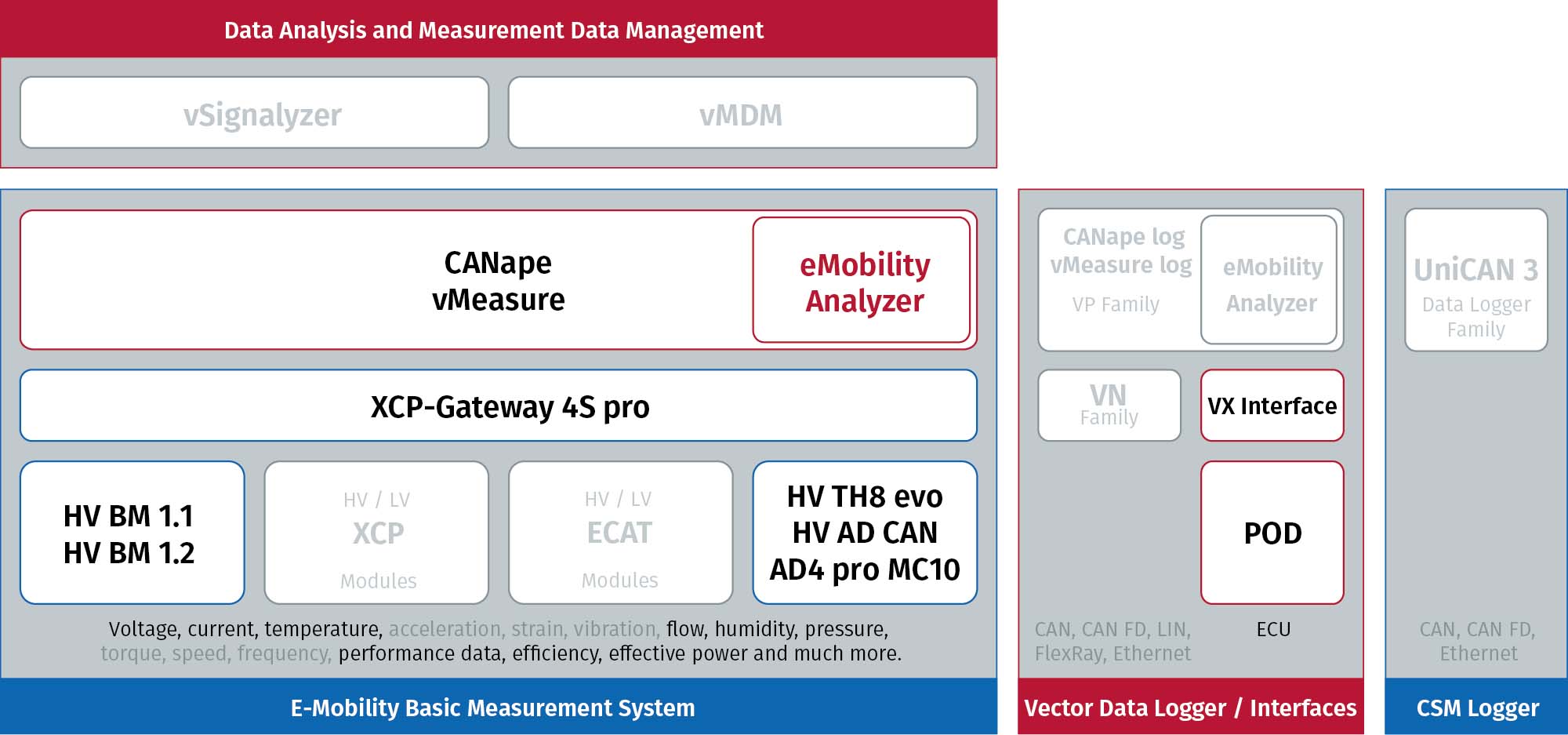

The CSM Measurement Solution

With measurement modules and other components from the Vector CSM E-Mobility Measurement System, the numerous measurement variables required can be acquired and the parameters precisely analyzed.

- HV AD Measurement Module

Acquisition of flow, humidity and pressures in the air oxygen supply system - HV TH8 evo

Acquisition of temperatures in the fuel cell stack - AD 4 pro MC10

Detection of flow rates in the hydrogen supply system - Vector VX Interface

Acquisition of data from the fuel cell control unit - HV Breakout-Module

Measurement of current, voltage and power - XCP-Gateway 4S pro

Synchronous acquisition of ECAT measurement data, bundling of CAN data and forwarding to the DAQ

- A measurement module AD4 pro MC10 acquires data from flow sensors in the hydrogen supply system.

- With a temperature measurement module HV TH8 evo, temperatures in the fuel cell stack are measured in a high-voltage-safe manner using conventional thermocouples.

- Numerous standard sensors measure flow, humidity and pressures in the oxygen supply. HV safety is ensured by a measurement module HV AD CAN that acquires the data from these sensors.

- HV Breakout Modules measure HV-safe current and voltage at various points in the fuel cell stack and the powertrain and calculate the instantaneous power.

- At locations that do not require HV-safe measurement technology, such as the circulation fan supply, the currents can be measured with LEM sensor packages.

- A Vector VX Interface acquires additional data from the fuel cell control unit.

- A XCP-Gateway 4S pro acquires all EtherCAT measurement data synchronously and bundles CAN measurement data. All acquired data is passed on to the DAQ.

Benefits

With the conventional and high-voltage measurement modules from CSM, the test bench can be equipped exactly according to the measurement requirements. High-voltage measurement modules are used where measurements are made in high-voltage environment. Fast EtherCAT measurement modules allow a high sampling rate to assure that high-speed transient data is not missed.

Thanks to the finely harmonized components of the Vector CSM E-Mobility Measurement System, the measurement setup can be scaled to specific applications and easily expanded as needed. For accurate power analysis, Vector's vMeasure software with the eMobilityAnalyzer is ideal.

More information

Further Information

-

CSM Xplained: Testing of fuel cell drives on test benches and in road testing

-

CSM Xplained: Maintenance of HV measurement technology – calibration and insulation-test

-

CSM Xplained: The Vector CSM E-Mobility Measurement System

-

CSM Xplained: Voltage measurement in e-mobility

-

CSM Xplained: Current measurement in e-mobility

-

CSM Xplained: Autonomous power measurement in road tests and on test benches

Related Products

Related Hardware

HV TH Measurement Modules

Safe temperature measurement with K-type thermocouples

Safe temperature measurements with thermocouples on high-voltage components: the high-voltage-safe temperature measurement modules are specifically designed for the reliable acquisition of temperatures in electric and hybrid vehicles.

XCP-Gateway

The protocol converter for EtherCAT® and CAN to XCP-on-Ethernet

XCP-Gateway is the interface between the data acquisition software (e. g. vMeasure, CANape®, INCA®, Vision® ...) and the EtherCAT® measurement modules from CSM. It includes an EtherCAT® master and an XCP-on-Ethernet slave.

HV AD CAN Measurement Modules

Measurement Ranges up to ±90 V

Safe acquisition of analog signals on high-voltage components: CSM’s HV AD measurement modules offer all-round measurement technology for sensors with analog voltage outputs or measurements of analog voltages up to ±90 V in high-voltage environments.

HV Breakout Modules 1.2

Single-phase measurement of internal conductor current and voltage

The HV Breakout Modules (BM) Type 1.2 have been specially designed for safe and precise single-phase measurement in separated HV+ and HV- power cables. Inner conductor current and voltage are measured directly and the instantaneous power is calculated in the module.

CAN AD MiniModules

Allround measurement modules for sensors with analog voltage outputs

CSM’s AD MiniModules of the AD CAN MM (MiniModule)-Series offer a wide range of applications for measuring analogue signals (voltage, current, pressure, flow rate, etc.).

The Vector CSM E-Mobility Measurement System

The measurement system for the development of electric mobility

Related Software

vMeasure

Reliably Solving Complex Measurement Tasks

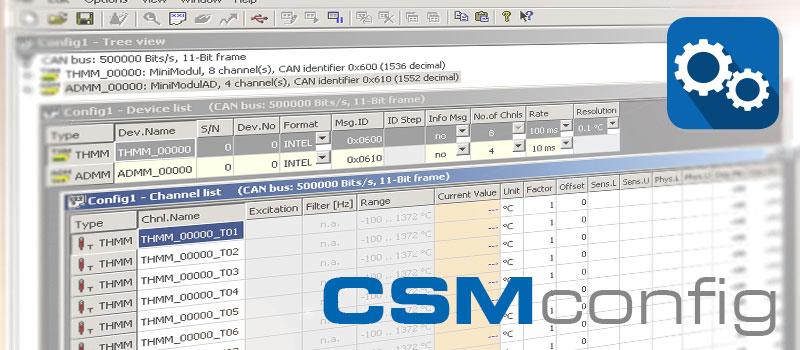

vMeasure is a subset of CANape focused on measurement. It is an easy-to-use software tool for the acquisition and analysis of measurement data that can be used in combination with all CAN- and EtherCAT®-based CSM measurement modules. CSMconfig was integrated directly to ensure swift configuration.

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.

Home

Home Newsletter

Newsletter