We support our customers with innovative measurement solutions for product development. Our measurement technology is used in many areas and at all stages of development. Especially in the area of high-voltage safe measurement technology, we were able to develop new solutions together with our customers. In the following we present a selection of possible applications of CSM measurement systems.

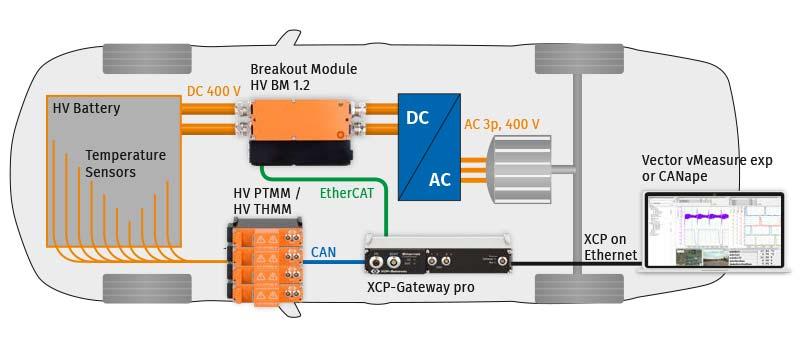

High-voltage batteries play a central role in the development of electric vehicles. Temperature management is one of the key factors for their optimal function, which is why temperature measurements are carried out under different conditions during development and pre-series production. The following example shows how such a temperature measurement can be realized in the high-voltage battery.

Read more: Temperature Measurement in High-Voltage Batteries

Temperature measurements during “thermal propagation”

Fully or partially electric cars are a promising alternative for sustainable mobility – however, the safe operation of high-voltage batteries plays a crucial role. Thermal propagation tests, i.e. the uncontrolled chain reaction of overheating that jumps from one cell to the next and can ultimately cause the battery to catch fire, are standard according to international norms. Together with measurement technology from CSM, Green Testing Lab from Austria therefore offers temperature tests on batteries during such an extreme event to develop optimization measures at an early stage and minimize potential risks.

Read more: Temperature measurements during “thermal propagation”

Thermal testing of HV batteries

The mobility transition is essentially determined by the battery-powered, electric drivetrain – the optimization of the HV battery is therefore an important adjusting screw. One parameter is the focus of testing: temperature. It is relevant for the flawless and efficient operation of the vehicle. Valuable findings for the safety and correct design of the system can be derived from observing the thermal behavior. This is a good reason to perform detailed and close-meshed measurements of the temperatures inside a traction battery.

Read more: Understanding and Early Prevention of Thermal Runaway

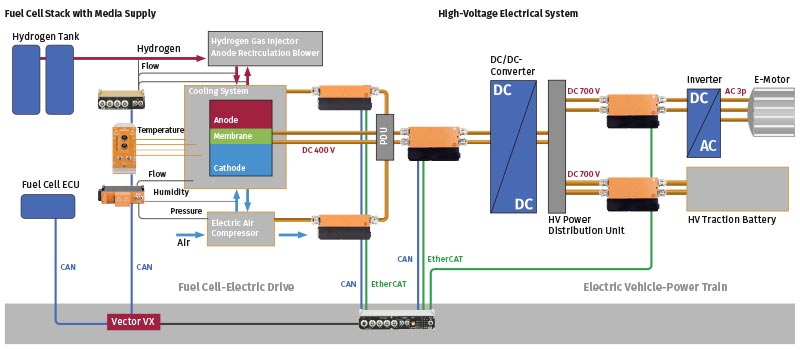

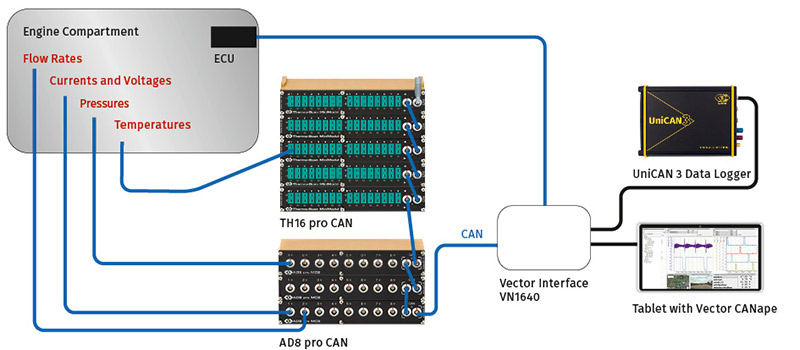

Fuel cell-powered vehicles are a complement to pure battery electric-powered vehicles in electromobility. An electrochemical reactor is used to generate electrical energy that is available for the drive and other vehicle systems. The interaction of this reactor in the fuel cell stack with the other components in the powertrain is tested on test benches. In this example, you will learn how the necessary measurements are carried out simply and synchronously.

Read more: Functional Testing of a Fuel Cell Drive on Test Benches

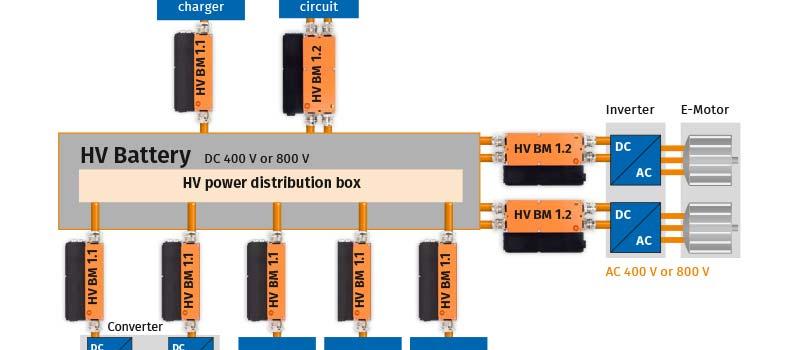

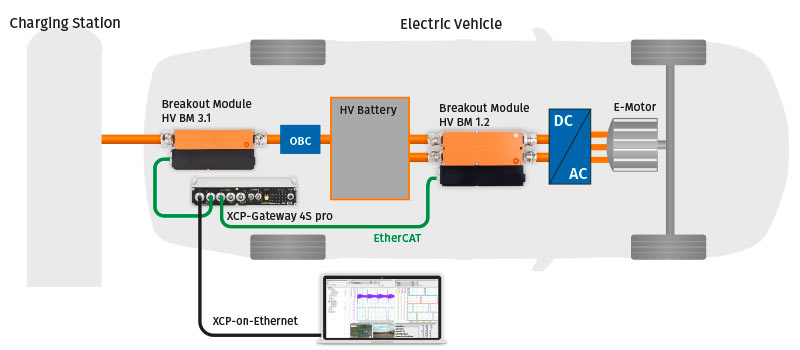

The high-voltage electrical system in electric and hybrid vehicles is validated at all stages of development and extensively tested for series production release. CSM HV Breakout Modules are particularly suitable for these validation and acceptance measurements in accordance with the ISO 21498-1 and -2 standard because they can be used directly in the HV cables of the vehicle electrical system.

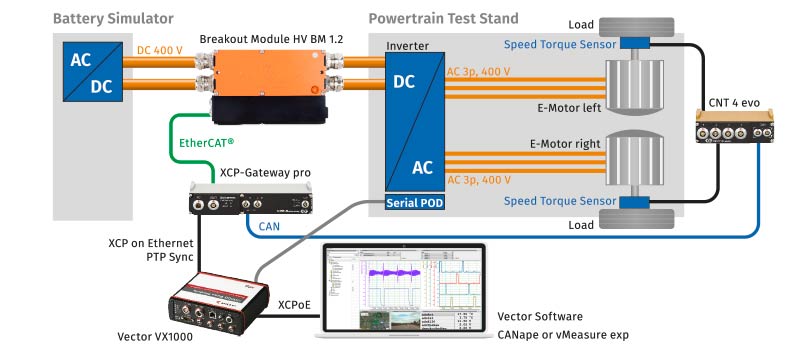

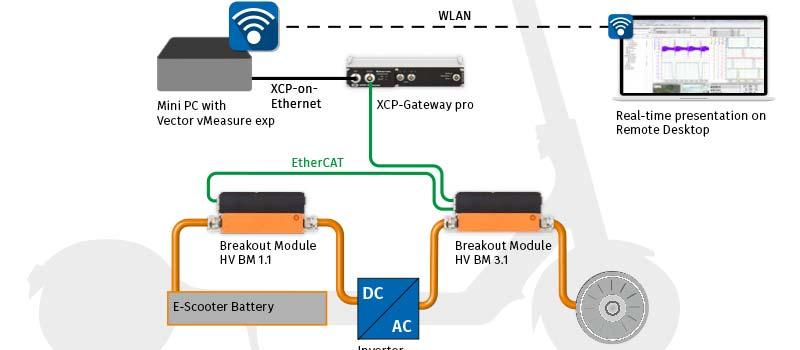

Electric powertrains have to be tested during many development phases. The overall efficiency is an important parameter for further optimization. In this application example, you can learn how the overall efficiency of fully integrated electrical powertrains is calculated in real time.

In the European Union, consumption values for new passenger cars and light commercial vehicles must be measured for type approval according to the WLTP (Worldwide Harmonized Light-Duty Vehicles Test Procedure). This also applies to electric vehicles (battery electric vehicles and hybrid electric vehicles), for which the electric range is also determined. This example shows how the electrical energy consumed and the range per charge can be determined according to the WLTP.

Read more: WLTP Power Measurement of Electric and Hybrid Vehicles

Comprehensively analyzing fuel cell drives using measurement technology

When people talk about hydrogen-powered vehicles, they usually mean a fuel cell drive. This generates the electricity required to drive the electric motor directly in the vehicle from the hydrogen tank. Although the chemical reaction occurs with just a few substances, certain conditions must be met for an ideal result. These include the temperature as well as the quality of the reaction components supplied. Comprehensive measurements – some of them requiring high-voltage safety – must be carried out to ensure that the fuel cell drive can be operated as efficiently and safely as possible.

Read more: Comprehensively analyzing fuel cell drives using...

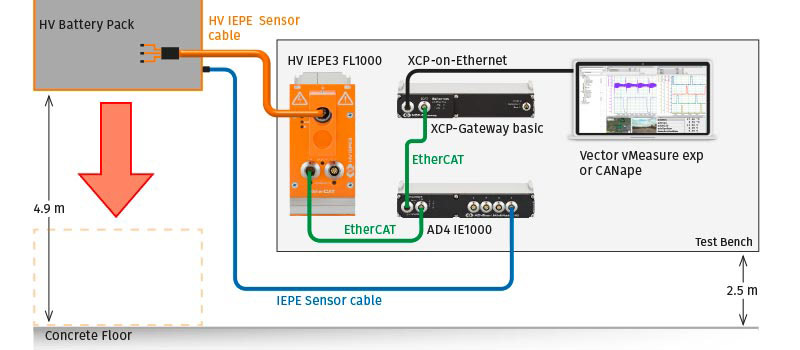

High-voltage-safe acceleration measurement in HV batteries

In the development of battery-powered electric vehicles, tests on high-voltage components must be performed in accordance with applicable standards and norms. To verify an electric vehicle for various national markets, accelerations inside and outside the traction battery must be measured during drop tests. If the HV battery does not pass the test according to the requirements – for example, because it is too severely damaged by the impact – further optimization is required. Green Testing Lab, a service provider in the field of battery testing, performs combined, synchronous measurements in special test environments using measurement technology from CSM.

Read more: Safe Drop Test Measurements for HV Electric Vehicle...

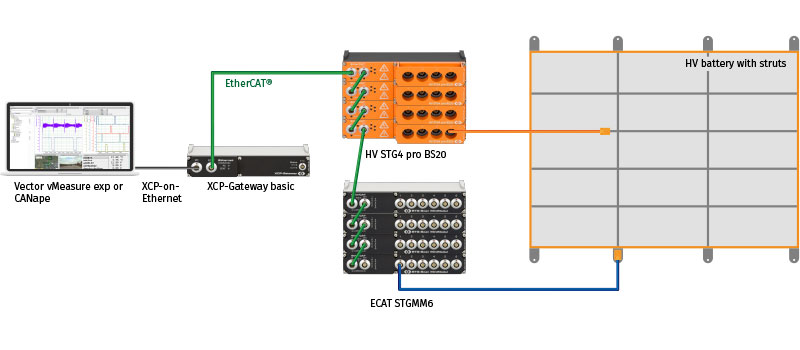

The housings of HV batteries not only serve to protect the battery cells and electronics inside them, but are also a structural part of the vehicle frame. Mechanical loads must be measured for an optimal housing design - inside and on the outside of the housing. This example shows how the necessary measurements are made easily and safely with strain gauges and strain gauges measurement modules.

Read more: High-voltage safe Strain Measurement in HV Batteries

Validation testing is often needed when extensive design updates are made to the vehicle system. In these cases, all important vehicle parameters are tested under a wide range of operating conditions. The following example shows how such tests are performed on forklifts that incorporated new engine options.

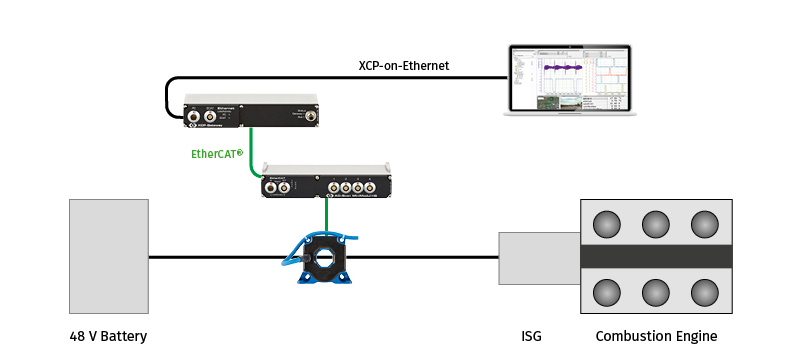

In order to further optimize efficiency and driving comfort, automobile manufacturers are using integrated starter generators (ISG) in mild hybrid vehicles. Fast current and voltage measurements are crucial for the optimal application of this technology. CSM offers the suitable measurement technology to perform measurements with high data rate and also in mobile testing.

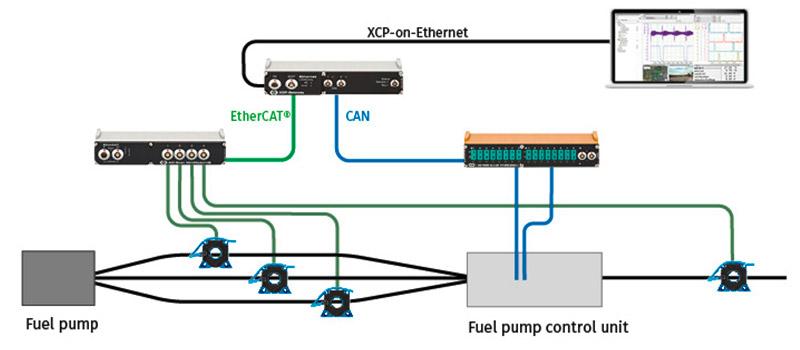

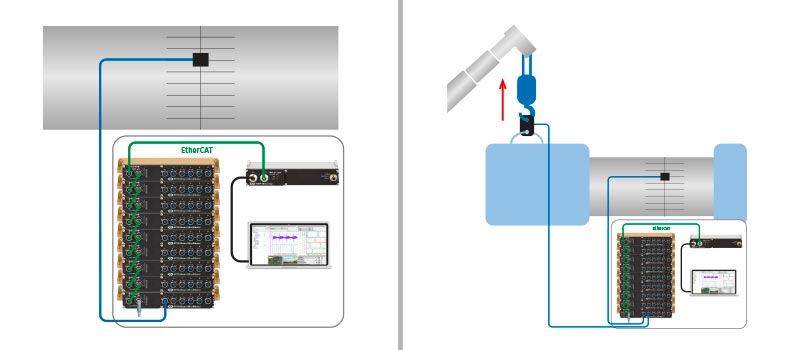

To further minimize fuel consumption, the fuel supply must also be regulated according to demand. The recording of current curves on the fuel pump control unit over a long period of time is intended to verify whether its fuse is correctly dimensioned. In the following application report you will learn how such a measurement can be carried out easily and how the advantages of CAN and EtherCAT-based measurement modules can be combined.

Offering long ranges for electric cars is one of the biggest challenges for vehicle manufacturers. The decisive factor here is the total energy consumption of the vehicle. Often, only the consumption of the electric powertrain is considered, but: How much does the low-voltage vehicle electrical system, which includes driver assistance systems and infotainment, contribute to discharging the drive battery? For competitive analyses, the currents of these components were therefore examined in more detail: Around 100 CSMshunts of different variants were used for benchmarking an e-SUV.

The range of electric vehicles determines their suitability for everyday use and acceptance by users. For a steady increase in range, the electric power trains and their components must be continuously optimized. The following example shows how an efficient power measurement in the low-voltage range is carried out. Similarly, such a measurement could also be made in the HV range.

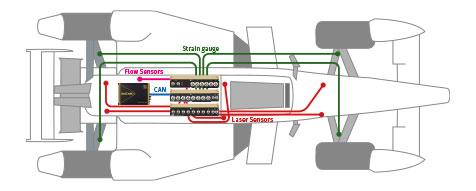

Motorsport places the toughest demands on man and machine; and also on the measurement technology that is indispensable for development. ABT Sportsline, together with Audi and Schaeffler, has used CSM's measurement technology in Formula E to obtain precise data during the development and testing of the racing cars. Find out in the following application report where CSM measurement technology was used.

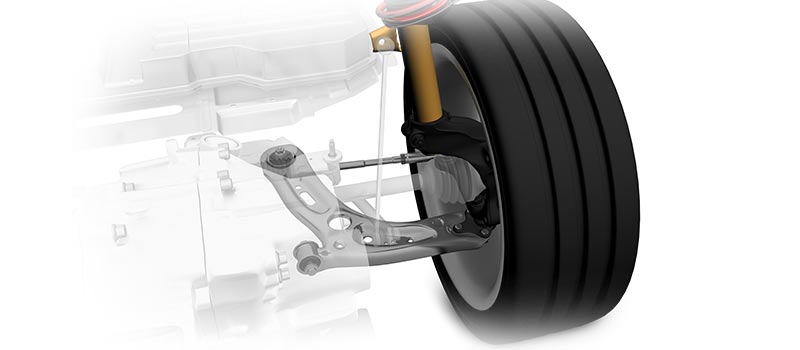

The optimization of hybrid and electric vehicles does not only extend to the electric drivetrain, but also includes all vehicle components. The aim is to save weight in order to achieve maximum performance and energy efficiency. At the same time, the vehicle must be permanently stable and safely designed for the planned service life. For this reason, chassis components are also tested and continuously improved with regard to mechanical stress. Measurement modules from CSM and telemetry measurement technology from AXON are used to measure the fatigue strength of parts of the wheel suspension.

Read more: Durability Measurement on Tie Rod and Axle Control Arms

Experimental stress analysis of components

Various tests are performed to determine the safety and adequate design of components. In the process, some test parts are stressed to the point of destruction. This approach is particularly important for elements that are subject to high mechanical stress, such as commercial and construction vehicles. Strain gauges are often used to measure the forces acting on the parts. The subsequent analysis of the measured data makes it possible to check if the system meets design intent.

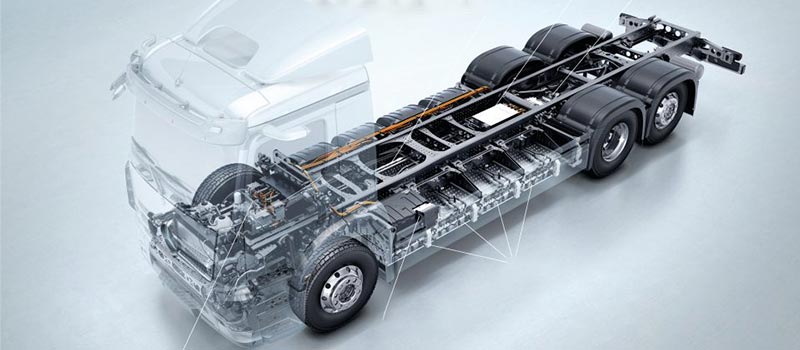

At Daimler Truck in Wörth (Germany), new trucks are being developed to production readiness. In road tests, the forces and torques acting on the rotating wheel are precisely recorded using the Kistler KiRoad Performance system. At the same time, CSM measurement technology is used to measure up to 200 analog channels in order to be able to make statements about the mechanical loads in the components. With the KiRoad Performance Gateway, which was developed specifically for this project, the measurement data from the various systems can be synchronously acquired and evaluated.

Read more: Measurement of Wheel Force for Durability Analysis at...

Along with the shift from combustion engine drives to electromobility, the question arises of where the electricity will come from to run e-motors in vehicles in the future. One idea: solar panels integrated into the vehicle to charge the battery. For this purpose, a fleet of solar-powered test vehicles has been developed as part of Sono Motors' Sion program. CSM accompanied the integration of the necessary measurement technology for acquiring the mechanical loads and the electrical power of the powertrain for one of the vehicles.

Sustainability and electrification on the road not only affect passenger transport, but also the areas of transportation and logistics. How commercial vehicles can be replaced by electric vehicles, especially on delivery routes in urban areas, confronts manufacturers with various challenges. While range and charging options are receding into the background, the peculiarities of inner-city traffic are a key issue. BPW Bergische Achsen KG from Wiehl in North Rhine-Westphalia (Germany) took on the task and developed an electric truck with a coaxial drive - supported by data loggers from CSM.

UniCAN 3 Data Logger

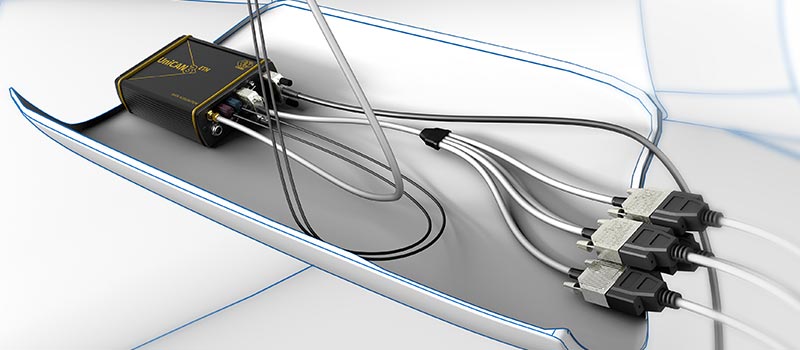

Intense sunlight and high temperatures mean stress for vehicles and components, and yet they are part of everyday life in many regions of the world. In order to test proper function under various conditions, cars are therefore driven worldwide by end customers in long-term tests during advanced development phases. During a fleet test of electric vehicles in Asia, very high ambient temperatures of more than +50°C were encountered. For the analysis the measurement results had to be reliably recorded despite the high load for the measurement technology used. With the UniCAN 3 data logger from CSM, the test could be carried out without loss of function or interruptions.

UniCAN 3 Data Logger

The development of hydrogen-powered trucks, whose electric motors are driven by electricity from fuel cells, initially required numerous tests on test benches. Various driving tests were then carried out in pre-series fleet tests. A data logger from CSM was installed to reliably record the results during both test situations: The UniCAN 3 was particularly impressive due to its configurability via remote access.

Read more: Flexible data recording wanted: Fuel cell trucks...

UniCAN 3 Data logger

During vehicle tests, often there are several vehicles sent into the field at the same time and are often equipped with data loggers. These record the data from the tests so that the underlying measurements can subsequently be analyzed. In most cases, status information from the data loggers or vehicle data can only be retrieved or analyzed reactively or with a delay. Correcting errors is then sometimes very time-consuming and expensive. Instead, how can information be obtained in real time so that problems can be recognized earlier? With the MQTT function of the UniCAN 3 data logger from CSM, this is possible.

Read more: Logger information and measurement data in real time

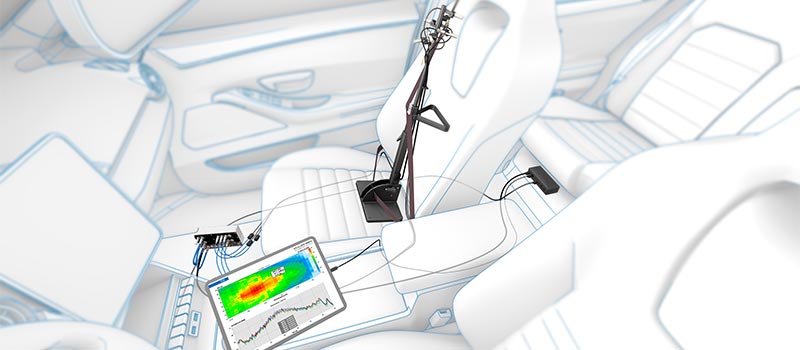

In addition to changes in current, voltage and power measurements, electric powertrains also bring new challenges for acoustics: The HV electrical system and its assemblies, new materials and the elimination of masking noise sources require a holistic view of acoustics and performance parameters. This application example shows how a harmonized measurement system can be used to acquire and analyze the necessary measured values.

Read more: High-voltage Measurement Technology and NVH in Mobile...