Measurements of the Mechanical Load of a Solar-powered Passenger Car Test Vehicle

Along with the shift from combustion engine drives to electromobility, the question arises of where the electricity will come from to run e-motors in vehicles in the future. One idea: solar panels integrated into the vehicle to charge the battery. For this purpose, a fleet of solar-powered test vehicles has been developed as part of Sono Motors' Sion program. CSM accompanied the integration of the necessary measurement technology for acquiring the mechanical loads and the electrical power of the powertrain for one of the vehicles.

Background

Sono Motors, a company based in Munich, Germany, manufactures solar modules that can be installed in the body of passenger cars or trucks either during production or as “aftermarket”. With its own passenger car, the concept should be implemented holistically.

For the construction of a new passenger car, the values from previous calculations for the dimensioning of the drive components and the battery, as well as the overall design had to be checked within the framework of the performance analysis and the durability. The requirement: To integrate a measurement setup in the vehicle that synchronously acquires the various measurement data from the components and at the same time is suitable for use in rough road tests.

For this reason, one of the test vehicles was completely equipped with measurement technology from CSM.1

Measurement Task

Acquisition of measured variables of fatigue strength (torsion, strains, accelerations, temperatures) as well as HV voltage and current in the electrical powertrain.

Challenge

"How does the vehicle behave while driving?" and "What forces affect the individual components?" are just some of the questions that precede measurements of mechanical stress.

The evaluation of operational stability, in other words the achievement of the planned durability of the materials, requires that acting forces (vibrations, torsion and acceleration) are measured on components such as the vehicle frame and battery assembly. For a measurement project of this scale, which includes several hundred measurement channels and numerous measured variables, data recording must also function safely and reliably while the vehicle is in motion.

The CSM Measurement Solution

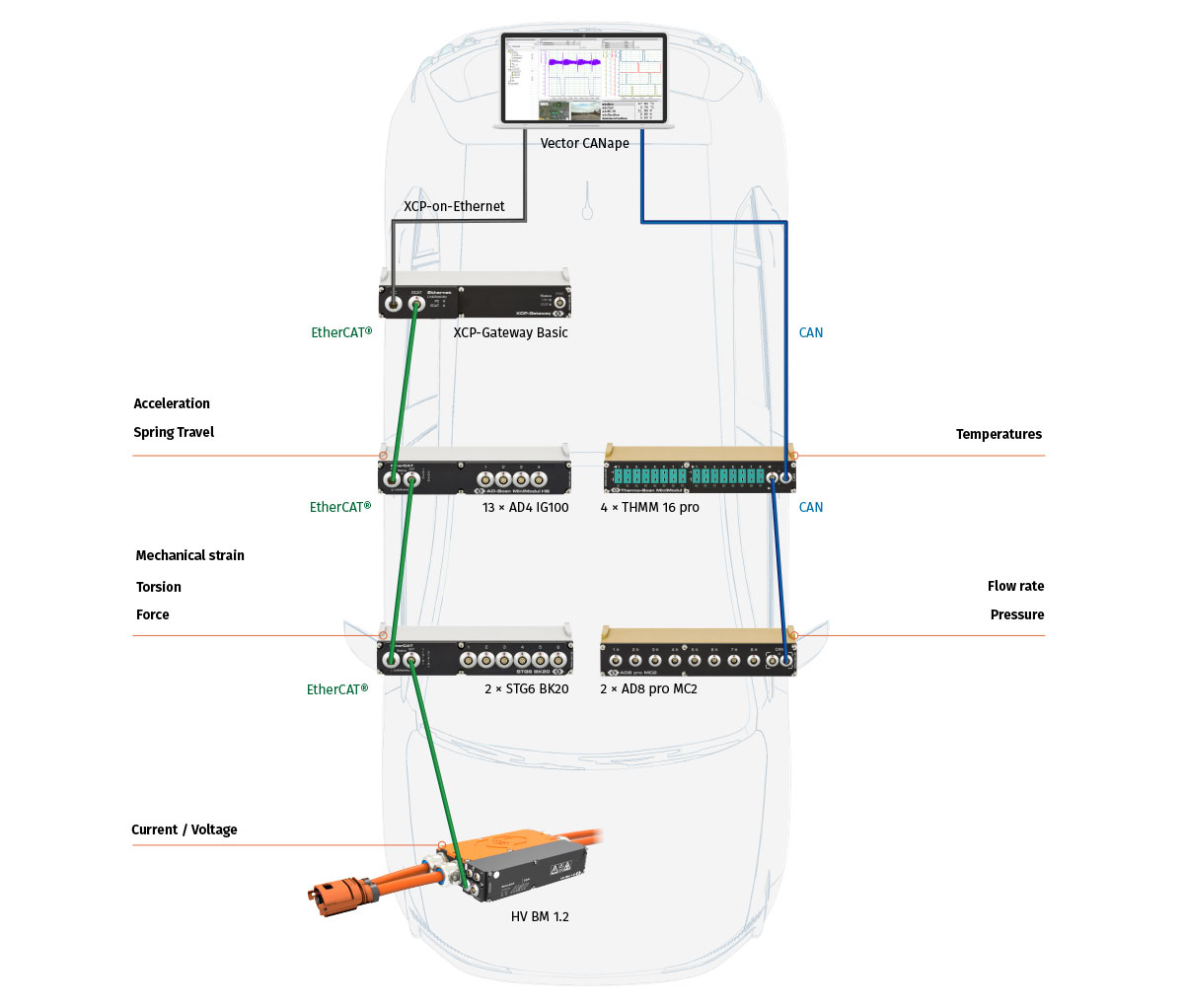

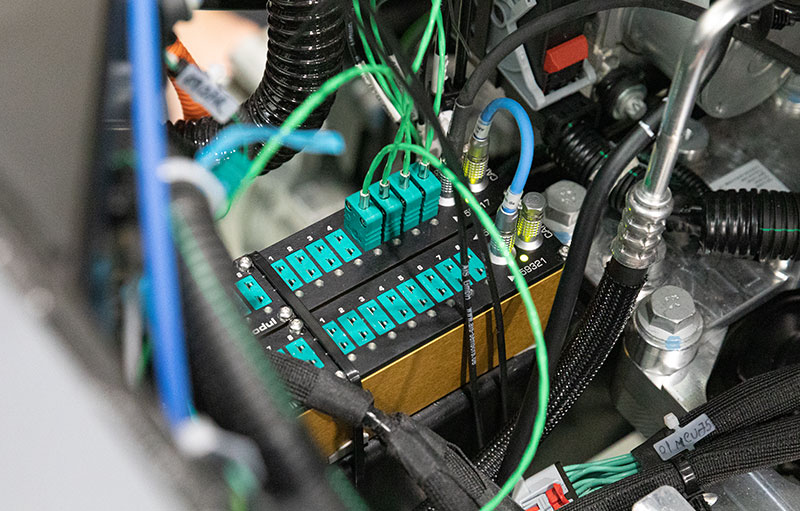

Components of the Vector CSM E-Mobility Measurement System were used to equip the test vehicle. To be able to comprehensively acquire and analyze all signals, a measurement setup with more than 200 measurement channels was necessary.

Measurement of mechanical loads

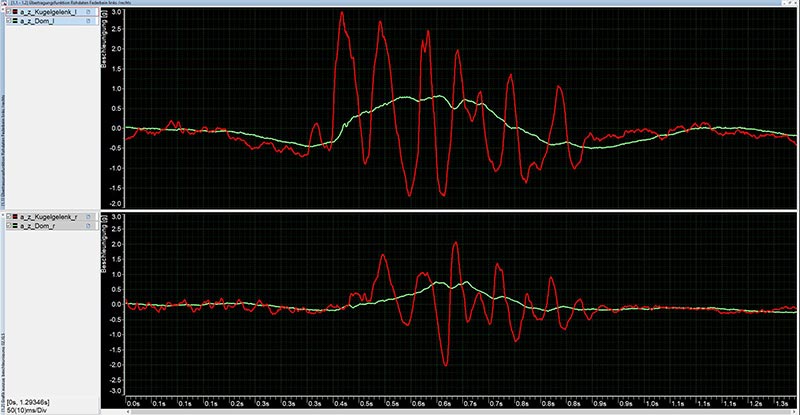

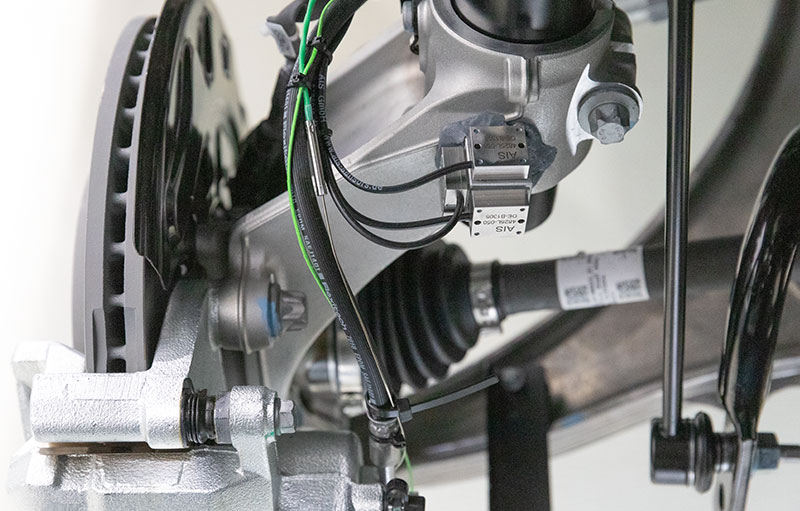

- Accelerometers, each measuring one axis, were attached to the wheel suspension and the frame. They record the movements of the components during driving. For the measurement of torsion of the battery and the frame, strain gauges were attached. From the data obtained, it was possible to deduce how large the forces acting at these points are.

- The sensor data of the strain gauges were transmitted via STG6 ECAT modules on an EtherCAT® network. The modules directly output the correct physical values, which eliminates the need for subsequent conversion. They also feature a ratiometric measuring principle that records the values in relation to the supply voltage - this simplifies scaling. In addition, the modules are characterized by low-noise behavior and thus enable nearly interference-free measured values.

- AD4 ECAT modules were used for the acceleration sensors; here, too, the data transmission was carried out with EtherCAT®. The very robust and compact IP67 rated housings of both STG6 and AD4 module types enable decentralized use in road tests.

Current / voltage measurements in the HV environment

- The High Voltage Breakout Module (HV BM) 1.2 was used for the HV-safe measurements of current and voltage between the battery and the inverter directly in the HV cables. The measured values were passed also transmitted using EtherCAT®, in this case enabling a time-synchronous evaluation of the data with sampling rates of up to 100 kHz.

Benefits

With the modular, distributed CSM measurement modules, a completely customized solution could be offered. The measurement technology solution from a single source and the synchronicity of the data made it possible to identify possible improvements from this correlated data. In addition to the measurement results for the individual vehicle areas and components, it was also possible to evaluate important test findings for the vehicle.

1 Unfortunately, the project had to be terminated in spring 2023. At the time of this report, no more tests with the vehicle have been performed.

More information

Related Products

Related Hardware

CAN AD MiniModules

Allround measurement modules for sensors with analog voltage outputs

CSM’s AD MiniModules of the AD CAN MM (MiniModule)-Series offer a wide range of applications for measuring analogue signals (voltage, current, pressure, flow rate, etc.).

CAN TH MiniModules

Temperature measurements with K-, J- and T-type thermocouples

CSM’s Thermo MiniModules allow precise distributed temperature measurements with K-, J- and T-type thermocouples: ideal for measurements in the powertrain, on HVAC (Heating, Ventilation, and Air-Conditioning) components, in the vehicle interior, the powertrain development and many more.

HV Breakout Modules 1.2

Single-phase measurement of internal conductor current and voltage

The HV Breakout Modules (BM) Type 1.2 have been specially designed for safe and precise single-phase measurement in separated HV+ and HV- power cables. Inner conductor current and voltage are measured directly and the instantaneous power is calculated in the module.

STG6 ECAT MM-Series

Fast distributed strain gauge measurements

Type STG6 pro BS20 | STG6 BK20

EtherCAT®-based measurement modules for decentralized use under demanding conditions: Robust, very compact and with six time-synchronous strain gauge inputs for quarter, half and full bridges.

XCP-Gateway

The protocol converter for EtherCAT® and CAN to XCP-on-Ethernet

XCP-Gateway is the interface between the data acquisition software (e. g. vMeasure, CANape®, INCA®, Vision® ...) and the EtherCAT® measurement modules from CSM. It includes an EtherCAT® master and an XCP-on-Ethernet slave.

Related Software

vMeasure

Reliably Solving Complex Measurement Tasks

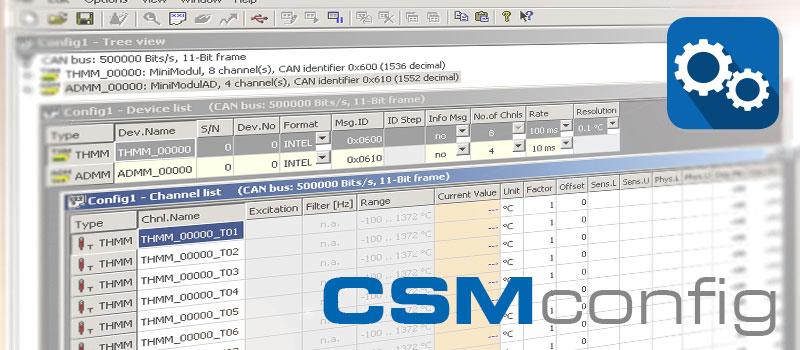

vMeasure is a subset of CANape focused on measurement. It is an easy-to-use software tool for the acquisition and analysis of measurement data that can be used in combination with all CAN- and EtherCAT®-based CSM measurement modules. CSMconfig was integrated directly to ensure swift configuration.

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.

Home

Home