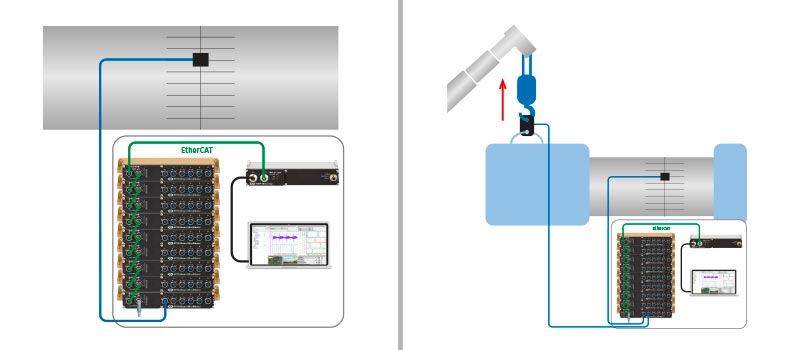

Here you will find our application examples on the performance of structural and fatigue measurements and mechanical load with strain gauges.

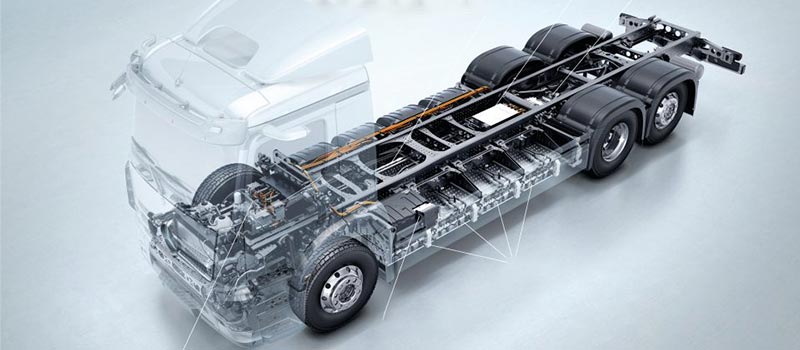

At Daimler Truck in Wörth (Germany), new trucks are being developed to production readiness. In road tests, the forces and torques acting on the rotating wheel are precisely recorded using the Kistler KiRoad Performance system. At the same time, CSM measurement technology is used to measure up to 200 analog channels in order to be able to make statements about the mechanical loads in the components. With the KiRoad Performance Gateway, which was developed specifically for this project, the measurement data from the various systems can be synchronously acquired and evaluated.

Read more: Measurement of Wheel Force for Durability Analysis at...

Along with the shift from combustion engine drives to electromobility, the question arises of where the electricity will come from to run e-motors in vehicles in the future. One idea: solar panels integrated into the vehicle to charge the battery. For this purpose, a fleet of solar-powered test vehicles has been developed as part of Sono Motors' Sion program. CSM accompanied the integration of the necessary measurement technology for acquiring the mechanical loads and the electrical power of the powertrain for one of the vehicles.

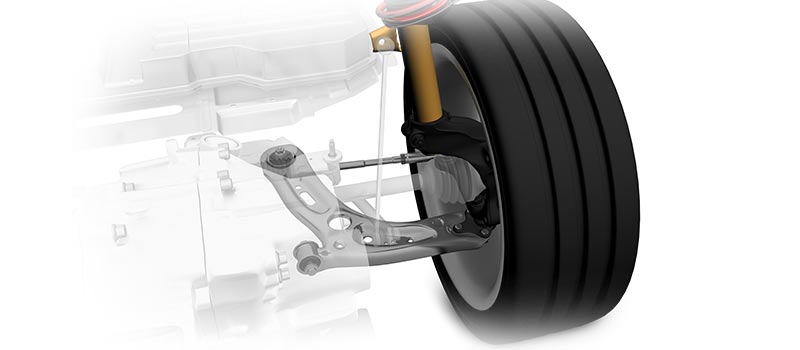

The optimization of hybrid and electric vehicles does not only extend to the electric drivetrain, but also includes all vehicle components. The aim is to save weight in order to achieve maximum performance and energy efficiency. At the same time, the vehicle must be permanently stable and safely designed for the planned service life. For this reason, chassis components are also tested and continuously improved with regard to mechanical stress. Measurement modules from CSM and telemetry measurement technology from AXON are used to measure the fatigue strength of parts of the wheel suspension.

Read more: Durability Measurement on Tie Rod and Axle Control Arms

Experimental stress analysis of components

Various tests are performed to determine the safety and adequate design of components. In the process, some test parts are stressed to the point of destruction. This approach is particularly important for elements that are subject to high mechanical stress, such as commercial and construction vehicles. Strain gauges are often used to measure the forces acting on the parts. The subsequent analysis of the measured data makes it possible to check if the system meets design intent.