Current and Voltage Measurements

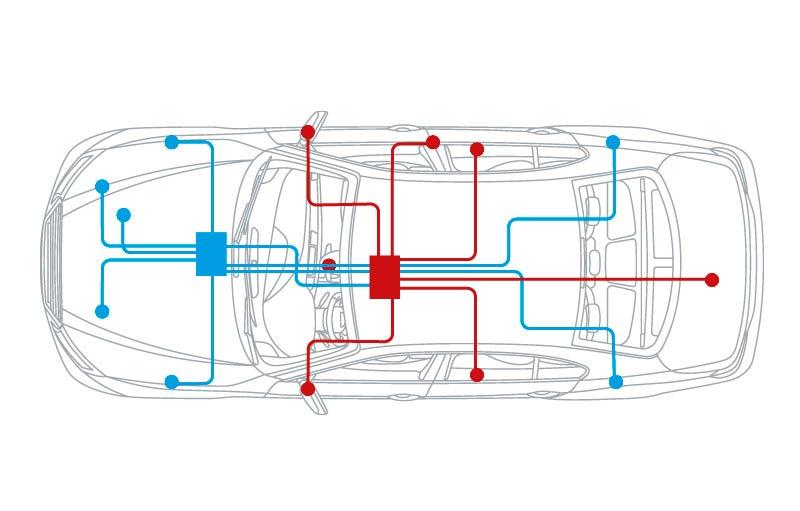

The number of electrical and electronic components in vehicles is constantly increasing. For an efficient design of vehicle electronics and electrics and the development of the vehicle electrical system, precise measurement of currents and voltages as well as power and energy consumption is therefore necessary.

Measurements in Different Types of Vehicle Electrical Systems

In 12-volt and 24-volt electrical systems, the voltages remain relatively stable, which is why CAN-based current measurements with Hall effect sensors or shunts can effectively be used.

The situation is completely different in the 48-volt and high-voltage electrical systems: Here, current and voltage measurements are equally important. Due to the high-frequency switching power electronics, as is part of inverters or DC/DC converters, current and voltage ripples are caused in the vehicle electrical system. These ripples can have a negative effect on the endurance of all consumers connected via the vehicle electrical system and can cause undesirable side effects. Via the DC/DC converters, these ripples can be transferred from the high-voltage electrical system to the 12-volt electrical system and cause problems there. For this reason, the electrical system must be validated according to the ISO/DIS 21498-1 and ISO/DIS 21498-2 standards using fast measurement technology.

Measurement modules for current and voltage measurements in high-voltage environments can be found here.

Testing in Harsh Conditions

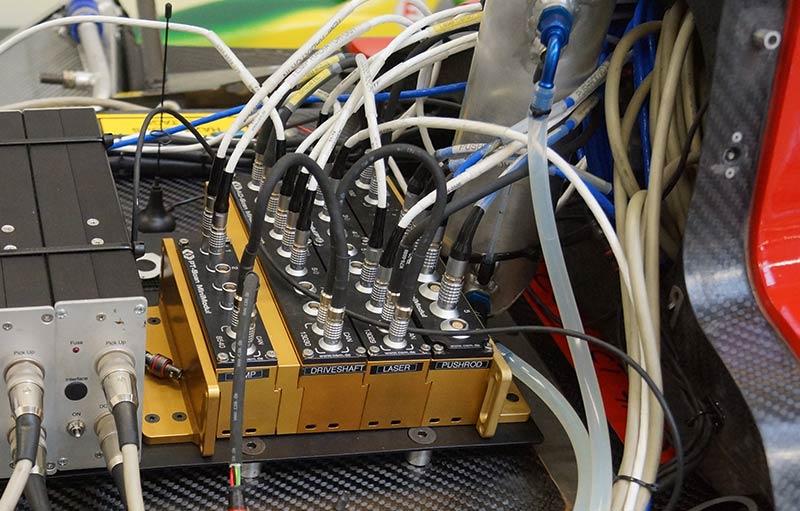

It is important to test current and voltage as well as the energy supply to the consumers under real operating conditions. This facilitates effective energy management and optimal operation of the vehicle under development. Examples include the safe interaction of the individual sensors, actuators and electronic control units in operating and stand-by periods. For precise current and voltage measurements in decentralized driving tests and on test bench, CSM offers compact and robust measurement modules and shunts.

Thanks to the high IP67 housing protection class, the compact design and the wide operating temperature range from -40 °C to +125 °C, the modules are ideally suited for harsh environmental conditions. They can be mounted directly in the engine compartment and thus close to the measurement points. This enables accurate measurements with interference limited to a minimum. In addition, measurement modules and shunts offer high measurement accuracy over the entire ambient temperature range due to their low intrinsic heat generation. The simple scalability of the measurement modules also makes them suitable for use on the test bench.

Related Products

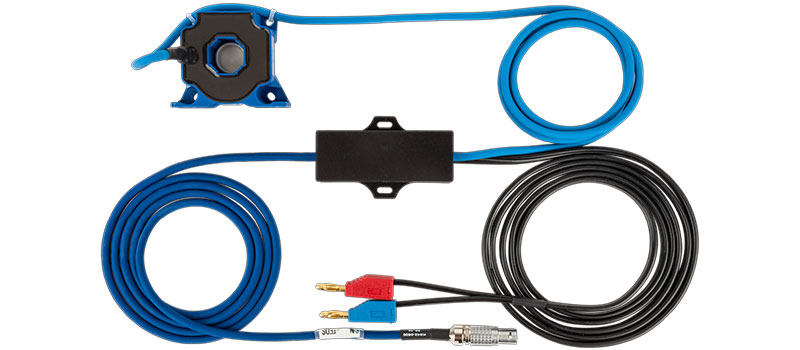

CSM Supply Unit HIOKI

Simple connection of HIOKI current sensors to CSM measurement technology

With the CSM Supply Unit HIOKI, HIOKI current sensors, e.g. current clamps, can be easily connected to CSM measurement technology for current measurements in 12 V /48 V vehicle electrical systems and HV environments. The supply unit provides the necessary supply voltage and allows direct connection to CSM measurement modules.

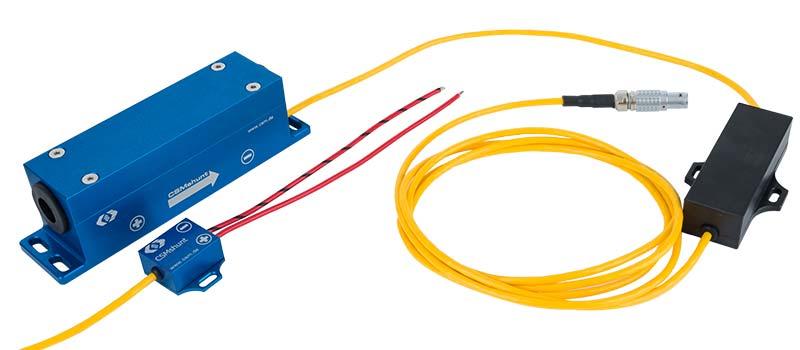

HV Breakout Modules

Measurement of internal conductor current and voltage as well as power measurement directly in HV cables

Home

Home