High-Voltage Measurements - Safe, fast and precise measurements with CSM

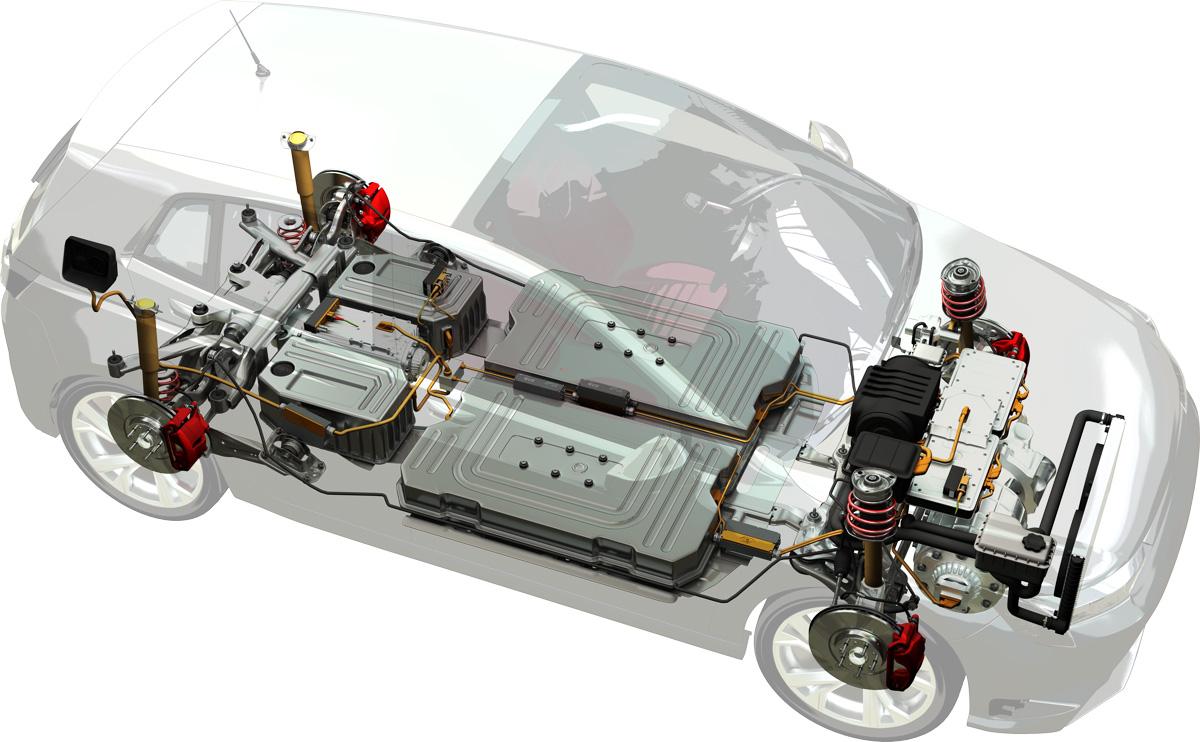

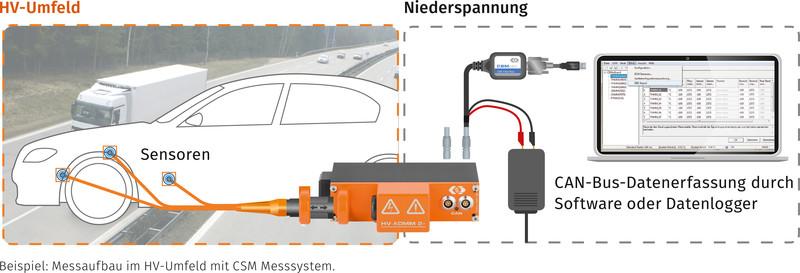

Electric mobility is the future of transportation. The development of modern electric and hybrid vehicles poses new challenges for measurement technology. Not only must the measurement technology for eMobility match the traditional attributes of being accurate, mobile, and easy to use, it must also be safe for the users and the system. CSM high-voltage measurement technology ensures the safety of all measurement applications by means of a HV safe measurement chain from the sensor to the data acquisition.

Electric mobility is the future of transportation. The development of modern electric and hybrid vehicles poses new challenges for measurement technology. Not only must the measurement technology for eMobility match the traditional attributes of being accurate, mobile, and easy to use, it must also be safe for the users and the system. CSM high-voltage measurement technology ensures the safety of all measurement applications by means of a HV safe measurement chain from the sensor to the data acquisition.

In addition, CSM’s HV measurement technology allows easy integration of existing sensors and measurement technology from low-voltage applications. Thus, the investment and training to implement safe HV measurement systems is optimized. The compact and robust design of CSM’s HV measurement modules allows use under all conditions: whether in distributed in a vehicle for field tests, or on the test bench. With CSM’s precise, high-speed measurement technology you can shape the mobility of the future.

Current and Voltage Measurement

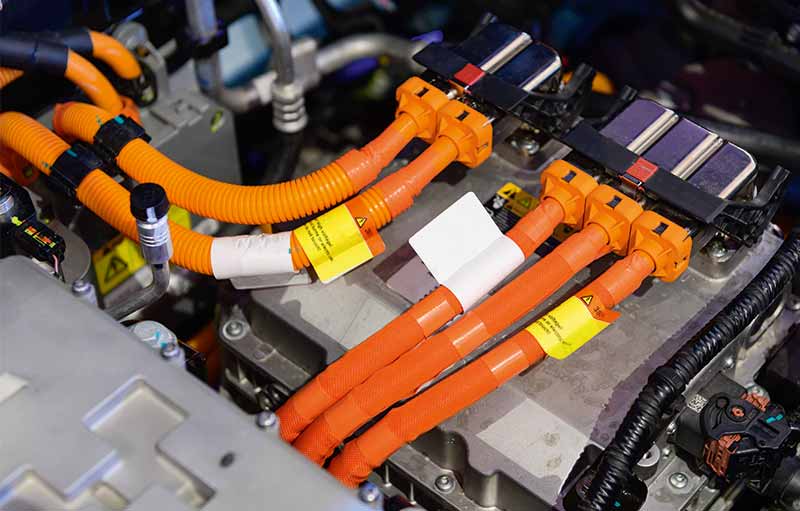

The current and voltage throughout an electric vehicle’s HV architecture must be measured and understood at every phase in development, including real operating conditions via field tests. The same rigor is required for the powertrain, the numerous accessory subsystems, converters, and power electronics in the vehicle. Even outside the vehicle, external charging infrastructure such as public charging stations and private home wall boxes need to be measured for their efficiency and safety.

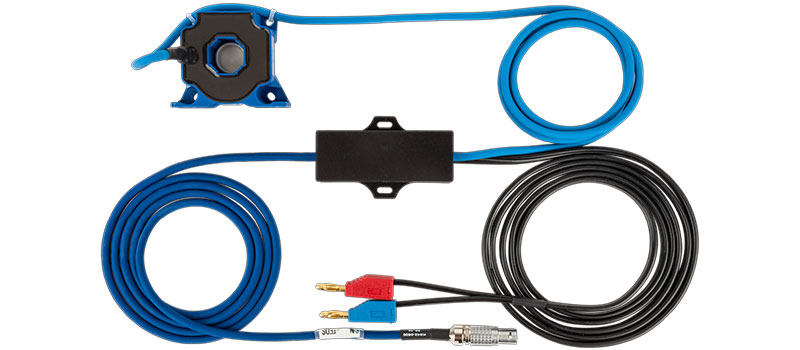

For fast, accurate, and synchronized measurement of current and voltage, CSM has developed the HV Breakout Modules, which offer a very simple solution: The measurement is carried out directly in the high-voltage power cables via a plug-in connection within an enclosed module. This enables precise measurements and maximum safety.

Related Products

HV Breakout Modules 1.2

Single-phase measurement of internal conductor current and voltage

HV Breakout Module 3.1

Three-phase measurement of internal conductor current, voltage and instantaneous power

HV Breakout Module 1.1

Single-phase measurement of internal conductor current and voltage

HV AD CAN Measurement Modules

Measurement Ranges up to ±90 V

HV AD CAN Measurement Modules

Measurement Ranges up to ±1000 V

Use Cases

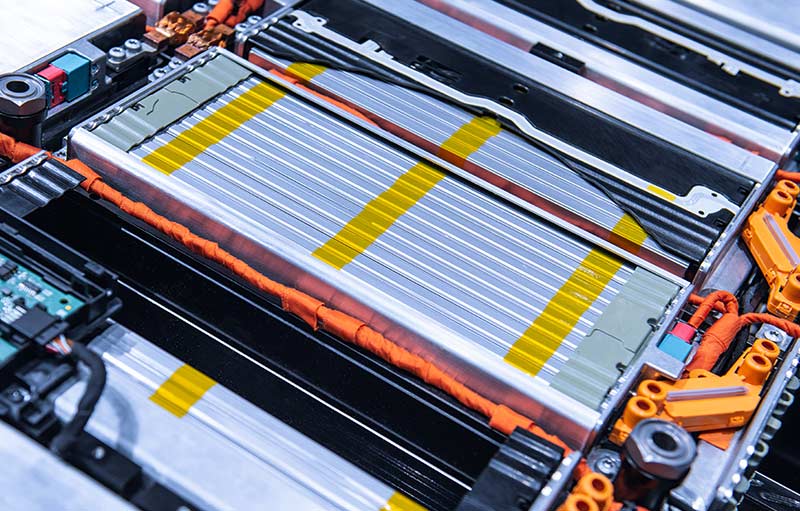

Temperature Measurement

An intelligent thermal management system is essential for the efficiency and longevity of electric vehicle subsystems. HV Batteries, inverters, motors, and other components must run optimally to reduce energy consumption and increase vehicle range per charge. These subsystems and their electronic components are within a high-voltage environment (eg.400 V or 800 V). The use of traditional measurement devices is potentially dangerous should the temperature sensor or its exposed cable become conductive. CSM’s HV safe measurement technology allows for the use of traditional temperature sensors and thermocouples, such as PT100 and PT1000 sensors or type T, J, and K thermocouples, within a HV environment. Utilizing proprietary isolation technology and cabling, the use of our HV modules assures the safety of both user and system

The HV battery itself requires proper thermal management. CSM’s HV safe measurement technology has been successfully deployed to thoroughly analyse and understand temperature variations between cells, packs/modules, and the overall assembly. The modules are ideally designed for use throughout the development phases from test bench to in-vehicle testing.

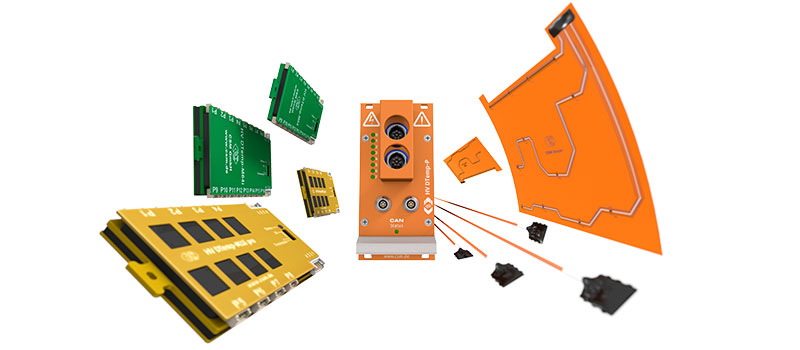

Related Products

HV TH Measurement Modules

Safe temperature measurement with K-type thermocouples

HV PT Measurement Modules

Safe temperature measurement with PT100 and PT1000 sensors

HV DTemp Measurement System

Digital measurement with up to 512 measurement points

Power Measurement

CSM offers various solutions for the digital measurement of electrical and mechanical power. For power measurement, current and voltage are synchronously measured with high time resolution up to 1 MHz within HV Breakout Modules. The values are recorded on a measurement computer and processed directly online with suitable analysis software, such as eMobilityAnalyzer package for CANape and vMeasure exp softwares from Vector Informatik. The eMobilityAnalyzer calculates active power, apparent power, power factor, energy and efficiency in real-time for single-phase or multi-phase power measurements. It can be used on both the DC and AC systems.

Related Products

HV Breakout Modules 1.2

Single-phase measurement of internal conductor current and voltage

HV Breakout Module 1.1

Single-phase measurement of internal conductor current and voltage

Autonomous power measurement in road tests and on test benches

The testing of electric drive systems requires a wide range of measurements and analyses of electrical power in the most varied degrees of detail. Depending on the application, extensive analyses including efficiency determinations may be necessary for the optimization of e-axles - while other contexts, such as the determination of consumption values, tend to benefit from independently performed power measurements.

- What the different requirements are for power measurement and power analysis.

- When power measurements in combination with compact data loggers are advantageous in road tests.

- Why independent power measurements with black box systems can also be useful on the test bench.

- What advantages a modular, scalable and expandable measurement system offers.

Download

Related Products

HV Breakout Modules

Measurement of internal conductor current and voltage as well as power measurement directly in HV cables

Measurement with Analog Sensors

Even in high-voltage environments, parameters such as moisture, pressure, acceleration, and strain must be measured. CSM offers a series of high-voltage safe measurement modules leveraging your investment in existing moisture, pressure, acceleration, vibration, etc. sensors from low-voltage applications. Specially developed HV safe sensor cables connect the sensors to the HV modules, thus ensuring safety from the sensor to the measuring module while simultaneously supplying the sensor excitation.

Related Products

HV AD CAN Measurement Modules

Measurement Ranges up to ±90 V

HV AD CAN Measurement Modules

Measurement Ranges up to ±1000 V

HV AD ECAT Measurement Module

Measurement Ranges up to ±1000 V and up to 1 MHz data rate

HV AD ECAT Measurement Modules

Measurement Ranges up to ±90 V and up to 1 MHz data rate

Measuring Mechanical Stress with Strain Gauges

In order to ensure the operational stability of all components, extensive tests and examinations of mechanical load must be carried out. For example, due to their dimensions and weight, high-voltage batteries in electric vehicles are often installed in the vehicle floor and are therefore exposed to loads like all structural elements in the vehicle. For the design and development of the battery housings, high-voltage safe measurements of the forces and mechanical stress must also be carried out within the HV environment. Via special cables, half and full bridges from low-voltage applications can also be used with CSM’s HV Strain Gauge modules.

Related Products

HV STG4 ECAT MM series

High-voltage safe measurement with strain gauges

Type HV STG4 pro BS20

CSM Safety Concept

The further development of electric mobility requires precise measurement results, but your safety is our top priority. For this reason we have developed a multi-stage safety concept.

- Each measurement module is subjected to a routine test in accordance with the safety standard EN 61010-1:2010 before delivery and a test certificate is provided to the customer

- An accredited test laboratory subjects the complete system of measuring modules and signal cables to a type test according to the safety standard EN 61010-1:2010

- Further tests include EMC (CE) tests, shock and vibration tests and protection class tests (IP65 / IP 67)

With our HV safe measurement modules and specially developed sensor cables, we ensure a safe transition from the high-voltage to the low-voltage environment.

For continuous testing of operational safety, we have developed our isolation test station, which can be used at the customer’s facility.

Related Products

Home

Home