Temperature Measurement in High-Voltage Batteries

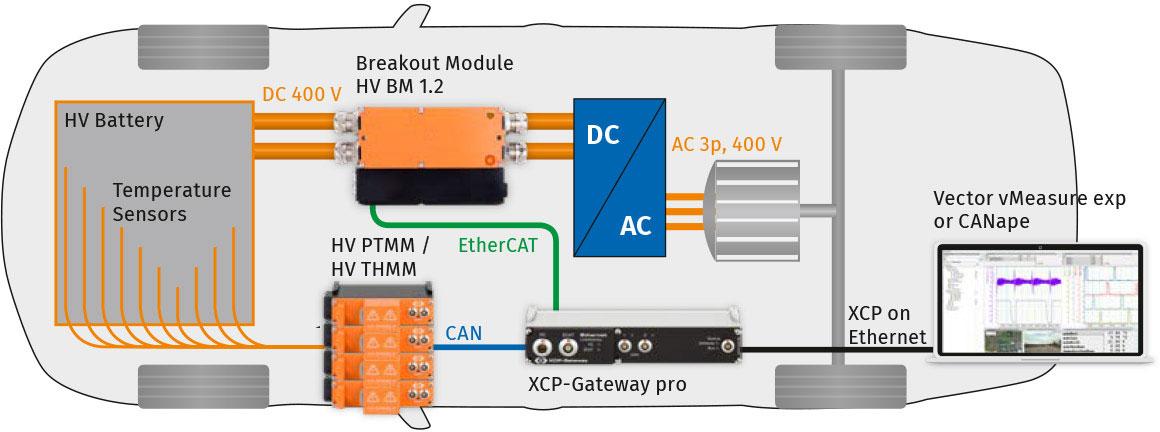

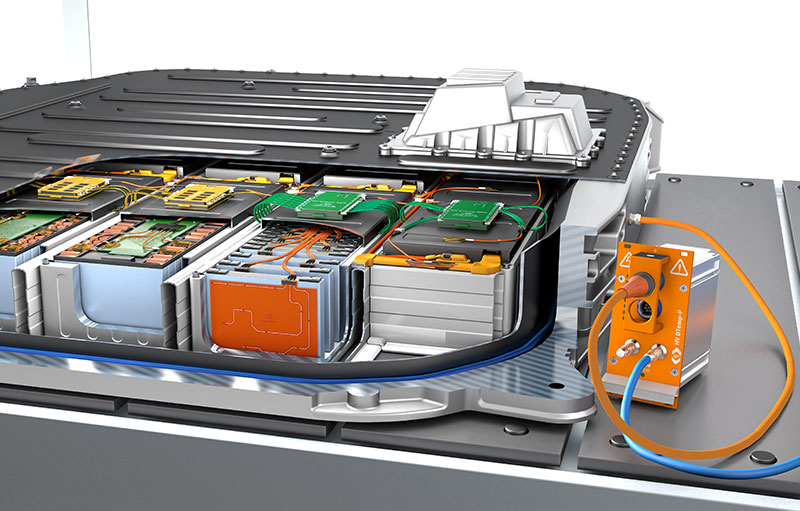

High-voltage batteries play a central role in the development of electric vehicles. Temperature management is one of the key factors for their optimal function, which is why temperature measurements are carried out under different conditions during development and pre-series production. The following example shows how such a temperature measurement can be realized in the high-voltage battery.

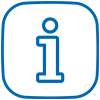

- XCP-Gateway

Connection of CAN and EtherCAT-based measurement modules and conversion to the XCP-on-Ethernet standard - Vector vMeasure

Data acquisition software and easy integration of CSM measurement technology - HV THMM

Acquisition of temperature data from thermocouples type K - HV PTMM

Acquisition of temperature data from PT100 or PT1000 sensors - Temperature sensors

PT sensors or thermocouples are used as required. - HV Breakout Module 1.2

Single-phase measurement of current and voltage as reference for the load condition of the battery

Measurement setup for temperature measurement and other measurement variables in high-voltage batteries.

Background

High-voltage battery cells require a certain temperature range to function optimally. Temperatures that are too low or too high can result in lower performance and faster aging. In order to keep the battery cells in the optimum temperature range, the overall battery system consists next to the battery cells, out of a cooling and heating system and the battery management system (BMS) with fault management.

Measurement task

Temperature measurements within the HV battery for optimum design of the cooling and heating system.

Challenge

The design of the BMS must be verified under changing conditions. This requires temperature measurements in the battery during various operating conditions, both on the test bench and in driving operation. The measurement technology must therefore be high-voltage safe and usable in the test bench and road test.

The CSM Measurement Solution

- By using highly accurate and very thin HV PT sensors it can be measured at almost any point within the battery.

- Alternatively, thermocouple temperature sensors can be used on a HV TH4 evo.

- Safety is ensured by special high-voltage sensor cables, which are fed into the battery system through screw connections, and the CSM high-voltage temperature measurement module HV PT2.

- If more in-depth analyses of the thermal behavior of the HV battery are needed, the HV DTemp Measurement System is suitable: This allows up to 512 IC temperature sensors to be installed in the battery and operated with a single central unit. With IC sensor technology on ultra-thin flexible circuits, the sensors can be placed precisely and reproducibly.

- A HV Breakout Module 1.2 simultaneously measures the battery current and the output power as a reference for the battery load level.

- A XCP Gateway pro combines the data transmitted by CAN and EtherCAT and converts them to XCP-on-Ethernet. This enables the use of common measurement data acquisition software such as vMeasure.

Benefits

In addition to the ensured high-voltage safety, the CSM measurement technology used can be installed in such a space-saving manner that it can be used both on the test bench and in road tests. This saves time for any necessary conversions. In addition, this solution can be easily extended by additional CAN or EtherCAT-based measurement modules (e.g. parallel moisture measurement in the high-voltage battery) by using an XCP Gateway pro.

- High-voltage safe

- Use in test bench and road test - without modification

- Extendable with other CSM measurement technology

More Information

Featured Products

Related Hardware

HV TH Measurement Modules

Safe temperature measurement with K-type thermocouples

Safe temperature measurements with thermocouples on high-voltage components: the high-voltage-safe temperature measurement modules are specifically designed for the reliable acquisition of temperatures in electric and hybrid vehicles.

HV PT Measurement Modules

Safe temperature measurement with PT100 and PT1000 sensors

CSM's HV PT measurement modules allow precise temperature measurements with PT100 and PT1000 resistance sensors in a high-voltage environment.

XCP-Gateway

The protocol converter for EtherCAT® and CAN to XCP-on-Ethernet

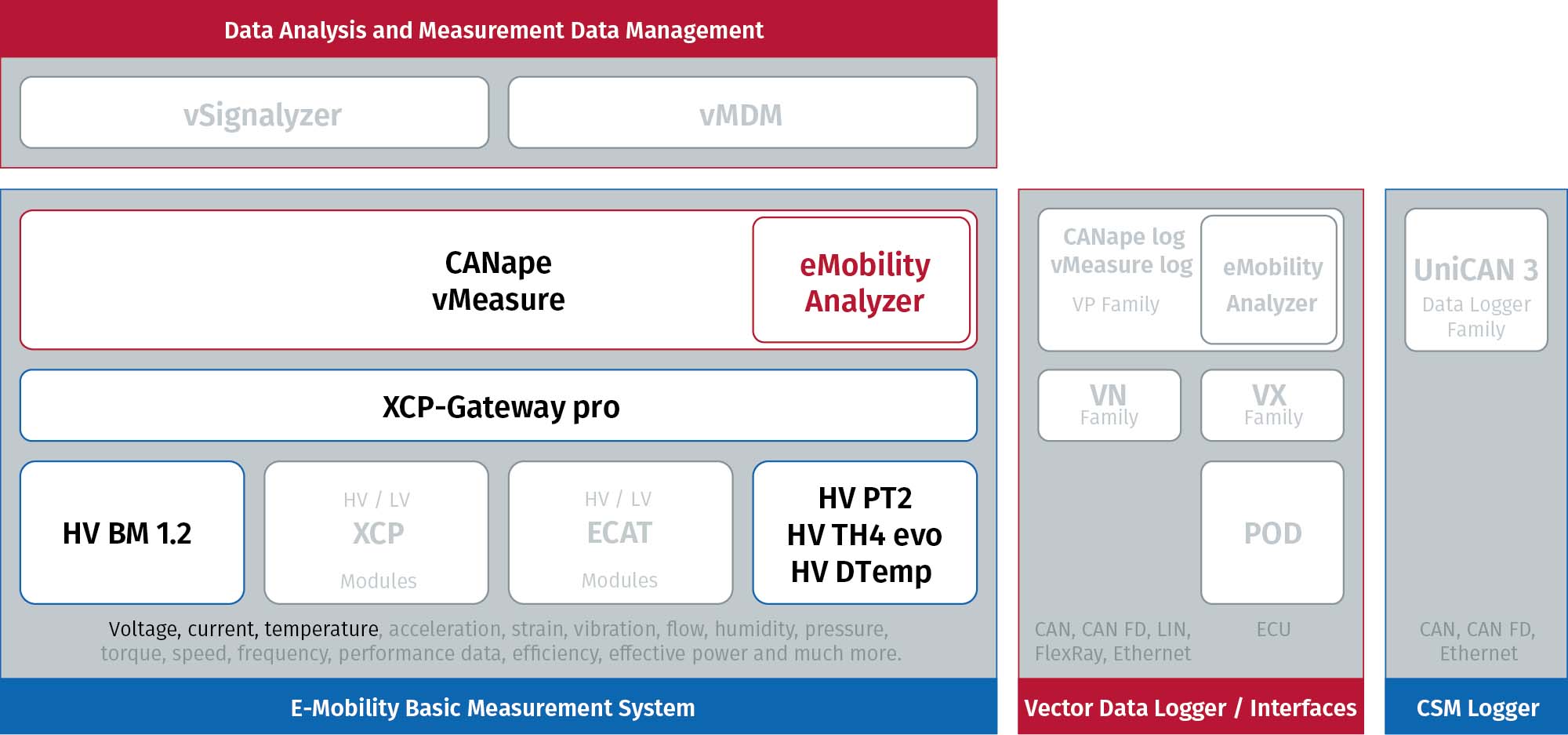

XCP-Gateway is the interface between the data acquisition software (e. g. vMeasure, CANape®, INCA®, Vision® ...) and the EtherCAT® measurement modules from CSM. It includes an EtherCAT® master and an XCP-on-Ethernet slave.

HV DTemp Measurement System

Digital measurement with up to 512 measurement points

The CSM HV DTemp measurement system is designed for the digital and precise measurement of up to 512 measurement points - temperature or humidity - via a single cable connection to the HV DTemp-P Central Unit.

The Vector CSM E-Mobility Measurement System

The measurement system for the development of electric mobility

Related Software

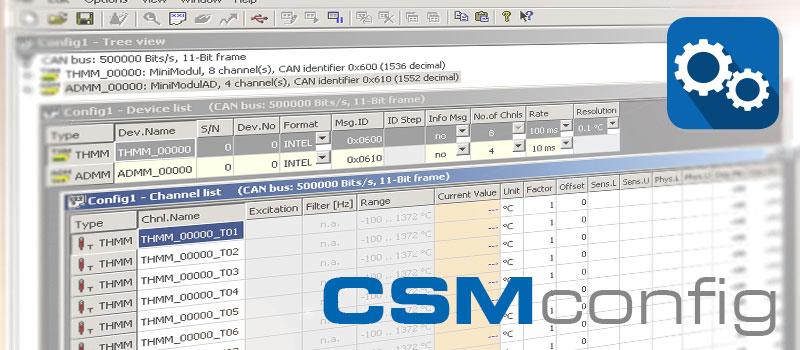

vMeasure

Reliably Solving Complex Measurement Tasks

vMeasure is a subset of CANape focused on measurement. It is an easy-to-use software tool for the acquisition and analysis of measurement data that can be used in combination with all CAN- and EtherCAT®-based CSM measurement modules. CSMconfig was integrated directly to ensure swift configuration.

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.

Home

Home