High-voltage-safe acceleration measurement in HV batteries

Dropping the HV Battery for more Safety

In the development of battery-powered electric vehicles, tests on high-voltage components must be performed in accordance with applicable standards and norms. To verify an electric vehicle for various national markets, accelerations inside and outside the traction battery must be measured during drop tests. If the HV battery does not pass the test according to the requirements – for example, because it is too severely damaged by the impact – further optimization is required. Green Testing Lab, a service provider in the field of battery testing, performs combined, synchronous measurements in special test environments using measurement technology from CSM.

Safety tests for worldwide sales

The use of high-voltage components in electric vehicles not only brings new technical challenges, but also requires components to meet new safety standards. These are primarily intended to prevent danger to people and possible damage to property – in every situation over the entire life cycle of the vehicle. This also includes different national drop tests for the high-voltage battery of electric cars. These drop tests must be successfully passed before the vehicles can be sold in the respective countries.

Joint expertise in testing

The company Green Testing Lab specializes in a range of standard-relevant tests on high-voltage batteries. Founded in 2020, various tests are performed in special test chambers at the site in Greinbach (Austria). Here, the impact of extreme conditions on the safety of high-voltage batteries is analyzed. Green Testing Lab uses measurement technology from CSM to test among other things vehicles for sale in South Korea: The “Korea Motor Vehicle Safety Standard” (KMVSS) requires a battery pack with a state of charge of 80% to hit a concrete floor from a height of 4.90 meters. The forces acting on the battery during the test can be used to determine how the component will behave in the event of an accident, for example.

Measurement task

Synchronous measurement of accelerations inside and outside a high-voltage battery during a drop test.

Setup for special requirements

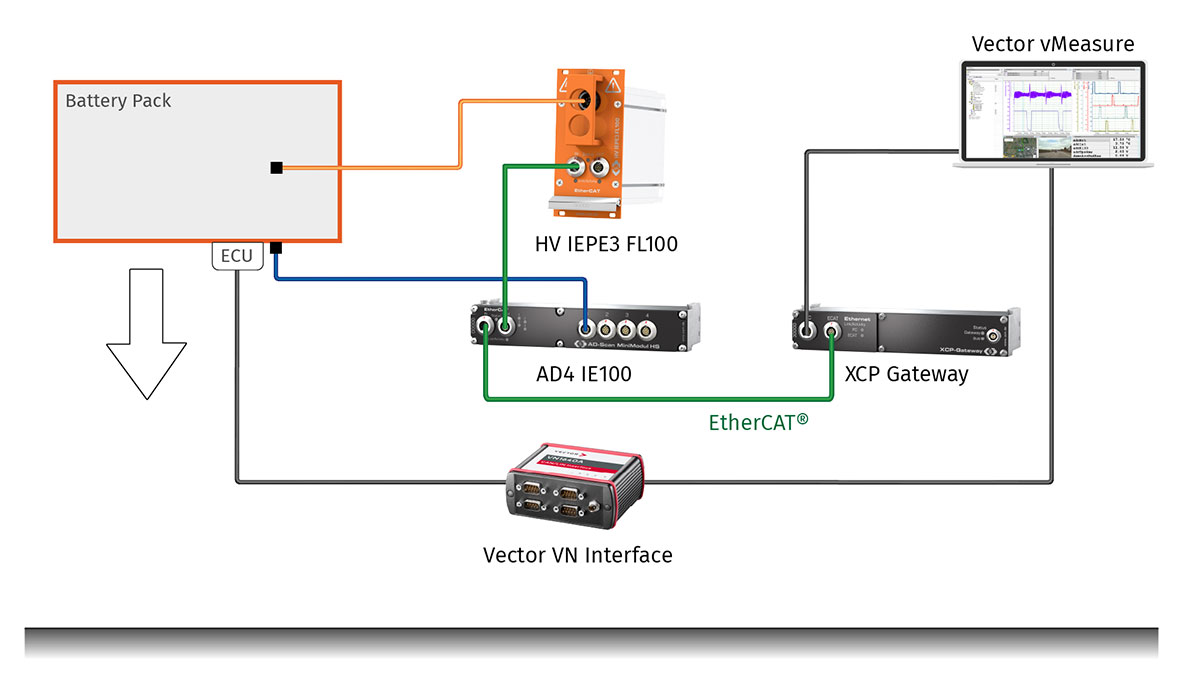

For the drop test to be successful, acceleration must be measured at various points inside and outside the HV battery. This means that different measurement technology must be combined: Inside the pack, the data is acquired in a high-voltage-safe manner and synchronized with measurement data from other acceleration sensors attached to the outside of the pack housing. By additionally acquiring the communication of the battery control unit, it is possible to check whether the safety mechanisms of the battery are functioning as planned.

Merging signals and acquiring the measured values

All measurement modules are placed at half the drop height to minimize interferences due to the optimal length of the sensor cables. For acceleration measurement within the pack, an HV-safe HV IEPE sensor cable is inserted into the high-voltage battery pack via cable glands and three commercially available uniaxial accelerometers are connected to it. The data from these accelerometers is acquired with the HV IEPE3 FL100 high-voltage measurement module at a data rate of up to 100 kHz per measurement channel. The data from other accelerometers attached to the outside of the battery pack housing is measured with the AD4 ECAT IE100. This module also allows a measurement data rate of up to 100 kHz per channel. An XCP-Gateway ensures the synchronization of the connected measurement modules using the distributed clocks method integrated in the Ethernet standard. It also acts as the interface to the data acquisition software by converting the signals to XCP-on-Ethernet. With vMeasure from Vector Informatik, the measured values can be analyzed and evaluated in accordance with the specifications of the South Korean standard. In addition, a Vector interface is used to record the data from the battery control unit via CAN to check what effects the forces from the drop have on the communication between the battery and the vehicle. This data is acquired and evaluated synchronously with the physical measured values.

"The integration of CSM's measurement technology with other products, especially with Vector's software, works perfectly. As a result, the measurement and evaluation of measurement data merge smoothly."

Max Hofer, Managing Director Green Testing Lab GmbH

In addition, several high-speed and infrared cameras are positioned around the measurement setup to visualize any damage or temperature changes to the battery.

Harmonized overall system

With the solution consisting of CSM measurement modules and Vector software and hardware, the battery test can be performed precisely in accordance with KMVSS specifications, as the high-voltage-safe measurement technology also allows the conditions within the battery pack to be measured. In addition, the CSM safety concept allows the simple use of known standard sensors in the HV environment and thus ensures an easy-to-implement measurement setup.

More Information

Featured Products

Related Hardware

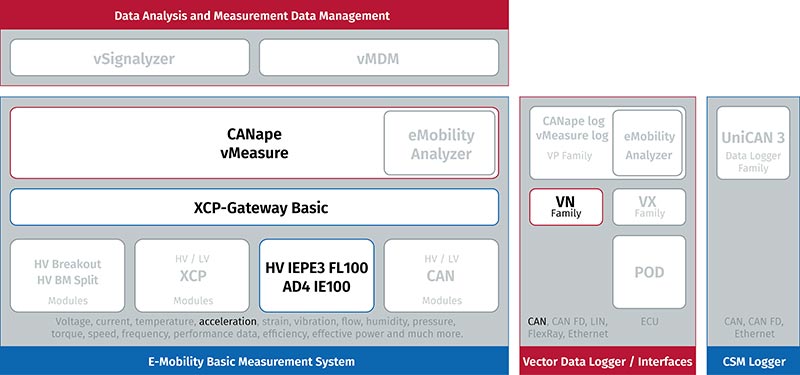

The Vector CSM E-Mobility Measurement System

The measurement system for the development of electric mobility

XCP-Gateway

The protocol converter for EtherCAT® and CAN to XCP-on-Ethernet

XCP-Gateway is the interface between the data acquisition software (e. g. vMeasure, CANape®, INCA®, Vision® ...) and the EtherCAT® measurement modules from CSM. It includes an EtherCAT® master and an XCP-on-Ethernet slave.

The FL100 has been specifically designed for measuring analog voltages from IEPE sensors, such as triaxial accelerometers, in high-voltage environments.

Related Software

vMeasure

Reliably Solving Complex Measurement Tasks

vMeasure is a subset of CANape focused on measurement. It is an easy-to-use software tool for the acquisition and analysis of measurement data that can be used in combination with all CAN- and EtherCAT®-based CSM measurement modules. CSMconfig was integrated directly to ensure swift configuration.

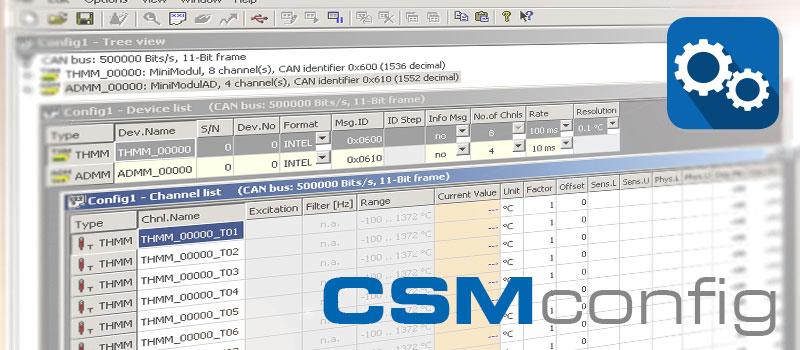

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.

Home

Home Newsletter

Newsletter