High-voltage safe measurement of mechanical strain in HV batteries

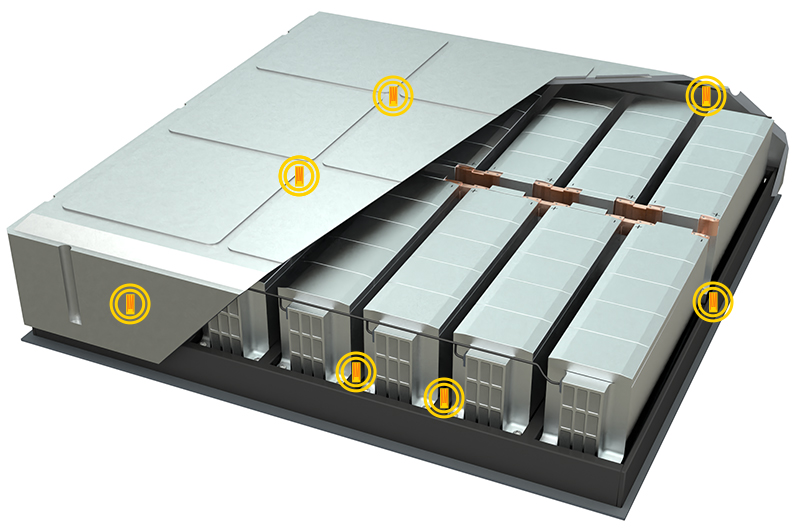

The housings of HV batteries not only serve to protect the battery cells and electronics inside them, but are also a structural part of the vehicle frame. Mechanical loads must be measured for an optimal housing design - inside and on the outside of the housing. This example shows how the necessary measurements are made easily and safely with strain gauges and strain gauges measurement modules.

Background

Housings protect HV batteries in electric vehicles from dirt, dust and moisture, thereby ensuring proper operation and safety for vehicle passengers. In addition to the protective function for the battery, the housing is also increasingly taking on structural tasks as a load-bearing element in the vehicle frame.

The housing is often made of steel, aluminum and plastic or a mixture of these materials and must be designed to be as light as possible with a high load capacity. For the optimum material design of the housing, the various mechanical loads acting on the housing must be taken into account.

- Inside the housing: During operation, the battery cells expand and forces act on the housing structures, such as struts between the battery modules.

- On the outside of the housing: As an element in the vehicle frame, the housing is also subject to impacts and torsion caused by the vehicle frame.

The housing must be able to withstand these stresses in any situation and must not break in order not to jeopardize the safety and proper operation of the battery.

Measurement task

Measurement of mechanical strains and stresses in a HV battery housing for optimal material design.

Challenge

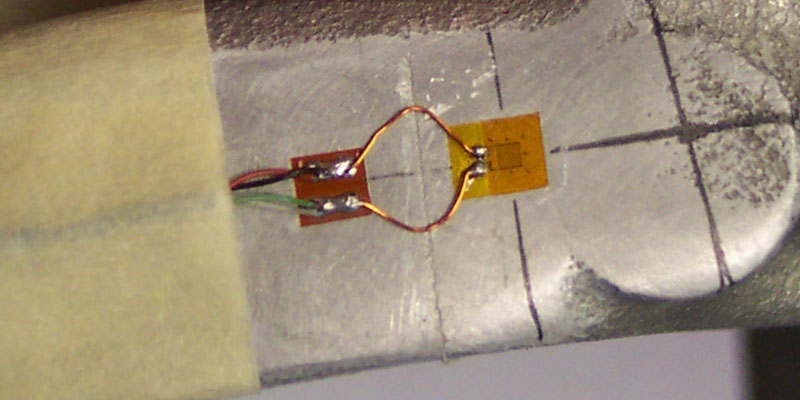

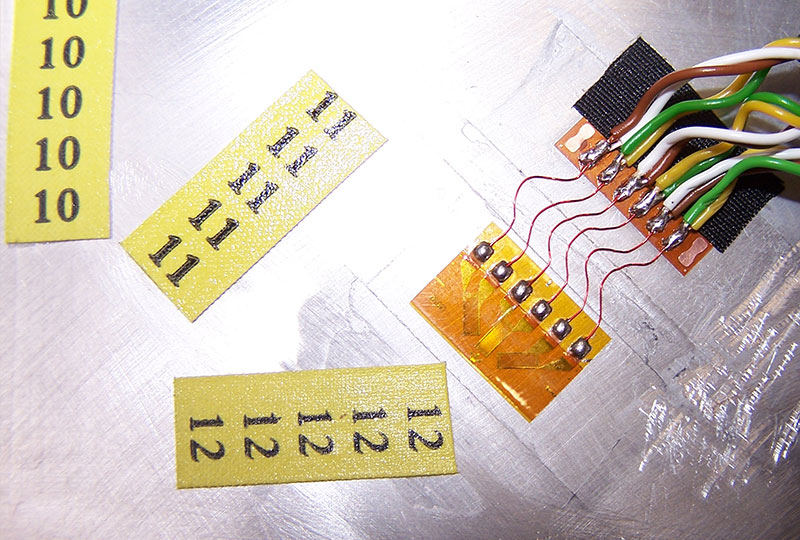

Strain gauges are used to measure strains and stresses on the inside and outside of the housing. For this purpose, the strain gauges will be applied as individual strain gauges and as rosettes. The measurements are to be carried out in road tests in order to obtain realistic load profiles.

For the measurements inside the housing, the necessary measurement technology must ensure HV safety.

The measurement range of the measurement modules must be adaptable to the specific material properties (aluminum, steel, plastic) and the expected size (e.g. ±1,000 µm/m).

It should be possible to adjust the measurement range and the supply voltage in the measurement module even after the strain gauges have been installed, so that smaller or higher strain values than initially expected can be acquired. And this without an additional calibration of the strain value.

Since strain often has to be correlated with other measurement variables, such as temperatures or accelerations, it should be possible to easily expand the measurement system with appropriate measurement modules.

The CSM Measurement Solution

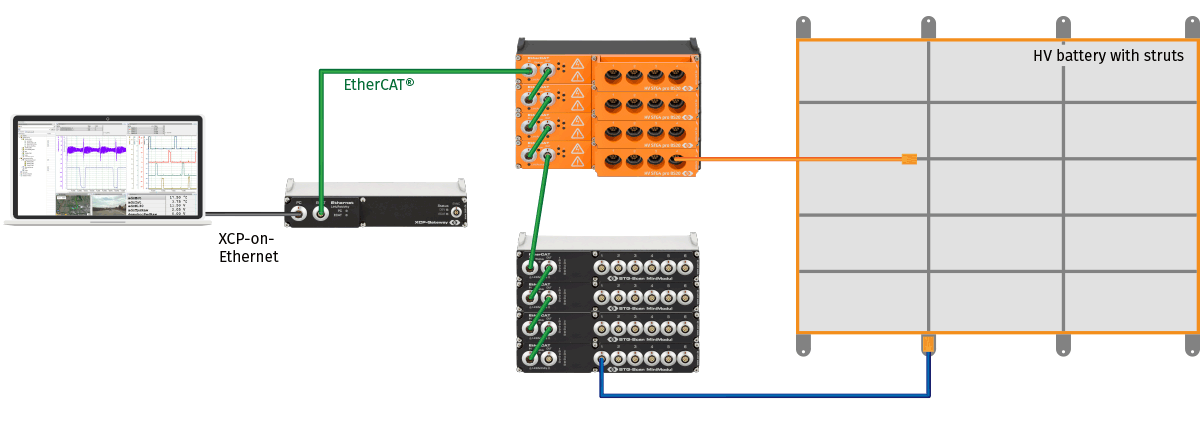

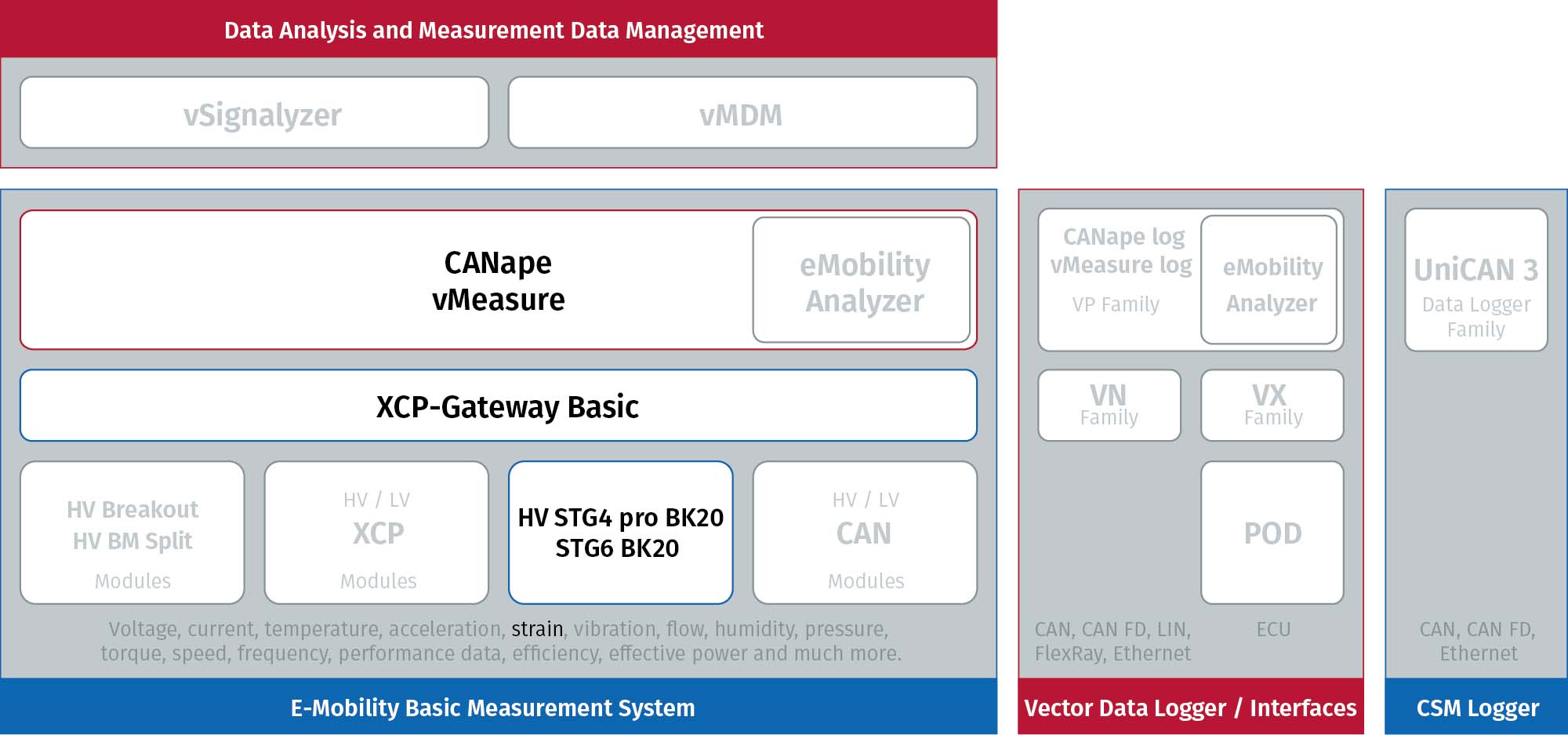

Measurement modules from the Vector CSM E-Mobility Measurement System are used to accurately analyze the strains and stresses inside and outside the battery housing.

- ECAT STG6 BK20

Acquire the data from the strain gauges on the outside of the housing - Strain gauges

Measure strains on the mountings of the battery housing - Strain gauges

Measure strains on struts inside the housing - HV STG4 pro BS 20

Acquire the data of the strain gauges from inside the housing - XCP-Gateway basic

Synchronous acquisition of measurement data from all modules and conversion to XCP-on-Ethernet - vMeasure or CANape

Acquisition of the measurement data

- The signals from the strain gauges in the battery housing and thus in the HV environment are acquired HV-safely by HV STG4 pro BS20. In conjunction with special sensor cables, conventional strain gauges designed for low-voltage applications can also be used in the HV environment. The extended input voltage range enables precise measurements from very low to very high signal voltages.

- The strain gauges on the mountings of the battery housing are outside the HV environment and thus no special safety measures are required. The signals of the strain gauges are acquired by ECAT STG6 BK20 .

- Both strain gauge measurement module types output the data directly as µm/m, thus avoiding subsequent conversions. If a subsequent change of the measurement ranges or the supply voltage is required, this can be done without further calibration or conversion, since the data acquisition is ratiometric. Thus, the set measurement variable in the module can remain set at µm/m without having to be corrected with a recalibration or recalculation.

- A XCP-Gateway Basic acquires the data from the measurement modules via EtherCAT® and synchronizes via the Precision Time Protocol (PTP). The data is converted to XCP-on-Ethernet and passed on to the DAQ.

Benefits

With this measurement technology solution, the mechanical strains inside and outside the battery housing can be measured. Due to the robust and compact design of the measurement modules, the measurement can also be carried out in road tests.

Other measurement modules can also be connected via the XCP-Gateway and their data acquired synchronously. For example, temperatures in the battery cells can be measured in parallel and included in the analysis.

More information

Download

Here you find the complete application report for download as PDF.

Related Products

Related Hardware

HV STG4 ECAT MM series

High-voltage safe measurement with strain gauges

Type HV STG4 pro BS20

EtherCAT®-based measurement module for distributed use under demanding conditions in the high-voltage environment: robust, extremely compact and with 4 time-synchronous strain gauge inputs.

XCP-Gateway

The protocol converter for EtherCAT® and CAN to XCP-on-Ethernet

XCP-Gateway is the interface between the data acquisition software (e. g. vMeasure, CANape®, INCA®, Vision® ...) and the EtherCAT® measurement modules from CSM. It includes an EtherCAT® master and an XCP-on-Ethernet slave.

STG6 ECAT MM-Series

Fast distributed strain gauge measurements

Type STG6 pro BS20 | STG6 BK20

EtherCAT®-based measurement modules for decentralized use under demanding conditions: Robust, very compact and with six time-synchronous strain gauge inputs for quarter, half and full bridges.

The Vector CSM E-Mobility Measurement System

The measurement system for the development of electric mobility

Related Software

vMeasure

Reliably Solving Complex Measurement Tasks

vMeasure is a subset of CANape focused on measurement. It is an easy-to-use software tool for the acquisition and analysis of measurement data that can be used in combination with all CAN- and EtherCAT®-based CSM measurement modules. CSMconfig was integrated directly to ensure swift configuration.

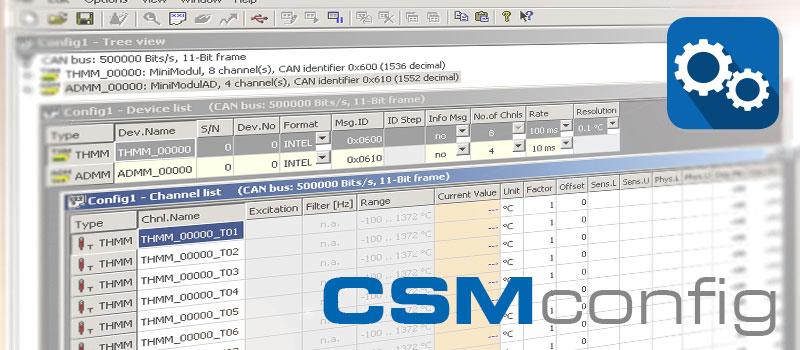

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.

Home

Home