Measurement of Wheel Force for Durability Analysis at Daimler Truck

At Daimler Truck in Wörth (Germany), new trucks are being developed to production readiness. In road tests, the forces and torques acting on the rotating wheel are precisely recorded using the Kistler KiRoad Performance system. At the same time, CSM measurement technology is used to measure up to 200 analog channels in order to be able to make statements about the mechanical loads in the components. With the KiRoad Performance Gateway, which was developed specifically for this project, the measurement data from the various systems can be synchronously acquired and evaluated.

Background

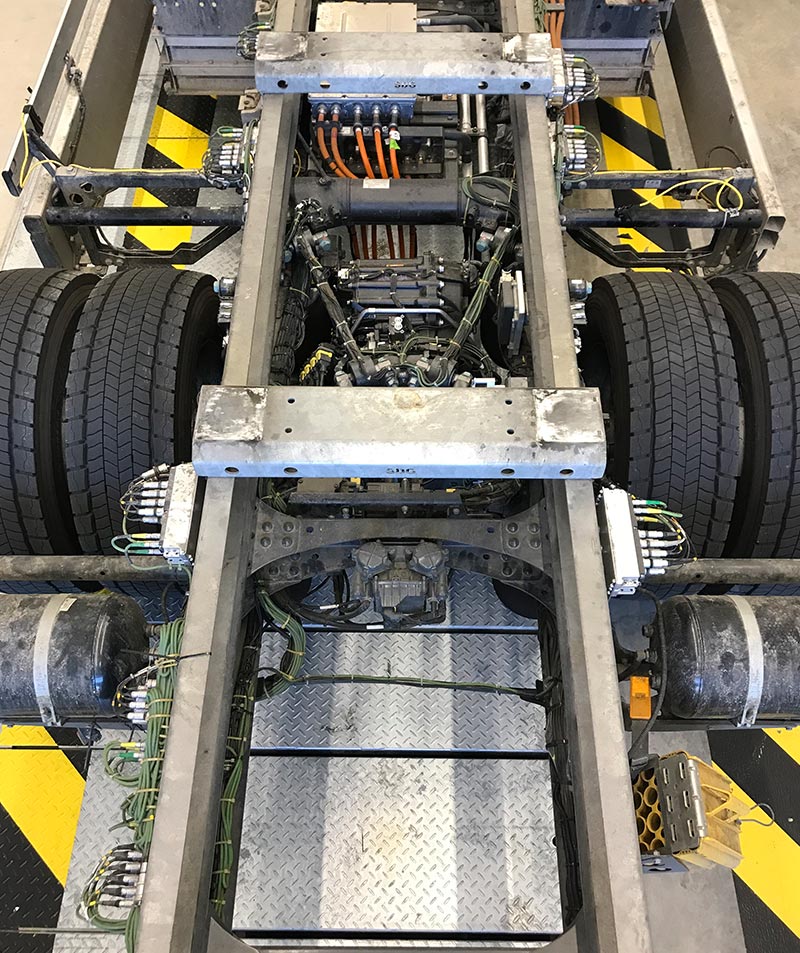

The mobility of the future and renewable energies are currently occupying the automotive industry: in 2021, the eActros, the first fully electric truck, was launched. The plan: further battery-electric vehicles are to be developed and launched on the market as quickly as possible. On the eActros, which is already in series production, the experience gained so far will be expanded.

This includes normal loads on public roads, such as potholes, but also special maneuvers. These cause forces to act via the wheels on the axle and into the vehicle frame, the effects of which have to be acquired and evaluated. On the test track for durability testing in Wörth, the service life of many hundreds of thousands of kilometers can be mapped in a shortened form.

Measurement Task

Synchronous acquisition of mechanical loads with the Kistler KiRoad system and CSM measurement modules for durability analyses.

Challenge

One challenge arises from the e-axle design and the associated arrangement of the individual components. In a conventional truck, the combustion engine is located at the front and power is transmitted to the rear axle along the length of the vehicle via a cardan shaft. In the electric eActros model, there is no longer any space for the drive shaft, as the battery modules are placed in this installation space. The electric motors are therefore integrated directly into the axle. Compared to the normal axle, the e-axle has a modified weight and a different center of gravity.

The measurement data obtained must correlate precisely in time to allow interpretation of the measured loads.

The CSM Measurement Solution

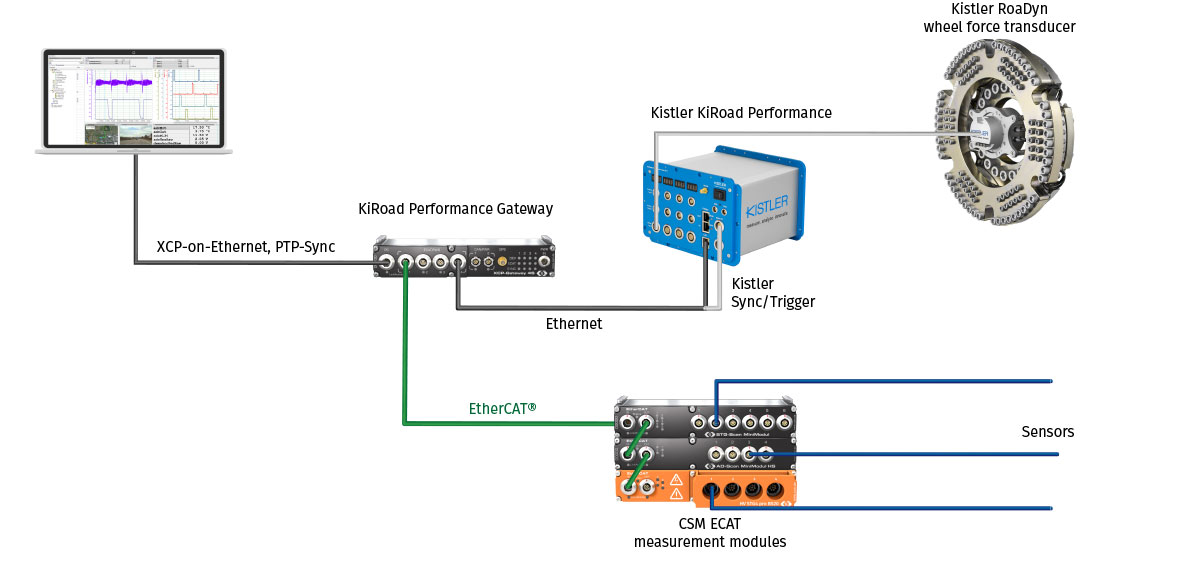

For simultaneous acquisition of the signals from the Kistler wheel force transducer and the analog sensor signals, CSM developed the KiRoad Performance Gateway.

The Kistler KiRoad Performance electronic unit and, in parallel, the CSM ECAT measurement modules for all analog channels required for the measurement are connected to it.

The KiRoad Performance Gateway synchronizes the clock supplied by the KiRoad measurement system with all other connected analog channels. This means both the measured values of both the CSM EtherCAT measurement technology and the Kistler KiRoad system are acquired simultaneously. They can thus be compared directly on the measurement computer.

Data acquisition and visualization are performed with Vector CANape or vMeasure. In addition, KiRoad Performance measurement data is now available PTP synchronously according to IEEE 1588.

Thanks to the measurement solution developed by CSM, it was thus possible to ensure that the transverse travel of the E-axis remains small enough, even with the highest transverse forces, to prevent collisions with neighboring components.

Benefits

A single module integrates Kistler wheel force transducer measurement into CSM measurement technology. This enables durability analyses to be performed more quickly and precise because the data correlation of mechanical load measurements and wheel force measurements is synchronized with high precision. It ensures better than 1μs synchronism for the entire system with the Precision Time Protocol (PTP according to IEEE 1588) without additional synchronization methods. Further applications, such as tests for vehicle dynamics, measurement of exact longitudinal and lateral dynamics or braking distance are possible.

More information

Related Products

Related Hardware

STG6 ECAT MM-Series

Fast distributed strain gauge measurements

Type STG6 pro BS20 | STG6 BK20

EtherCAT®-based measurement modules for decentralized use under demanding conditions: Robust, very compact and with six time-synchronous strain gauge inputs for quarter, half and full bridges.

Related Software

vMeasure

Reliably Solving Complex Measurement Tasks

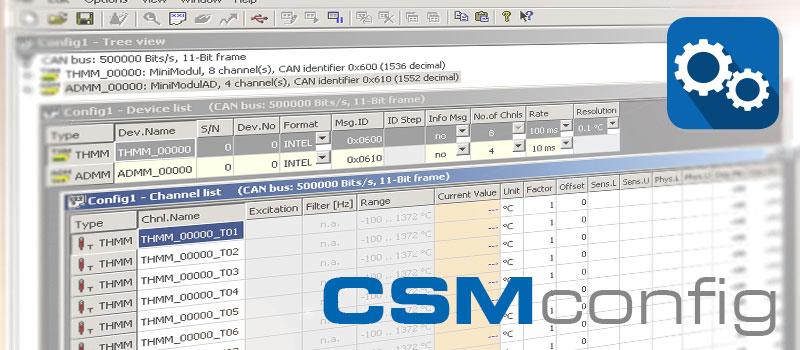

vMeasure is a subset of CANape focused on measurement. It is an easy-to-use software tool for the acquisition and analysis of measurement data that can be used in combination with all CAN- and EtherCAT®-based CSM measurement modules. CSMconfig was integrated directly to ensure swift configuration.

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.

Home

Home Newsletter

Newsletter