Green logistics in urban areas realized with smart (measurement) technology

Sustainability and electrification on the road not only affect passenger transport, but also the areas of transportation and logistics. How commercial vehicles can be replaced by electric vehicles, especially on delivery routes in urban areas, confronts manufacturers with various challenges. While range and charging options are receding into the background, the peculiarities of inner-city traffic are a key issue. BPW Bergische Achsen KG from Wiehl in North Rhine-Westphalia (Germany) took on the task and developed an electric truck with a coaxial drive - supported by data loggers from CSM.

Required data basis

When talking about electromobility in cities, commercial vehicles cannot be left out of the equation. Low-emission, short journeys in urban areas - with a lot of downtime for loading and unloading - which in turn can be used to charge the traction battery, offer ideal conditions for the use of an electric truck.

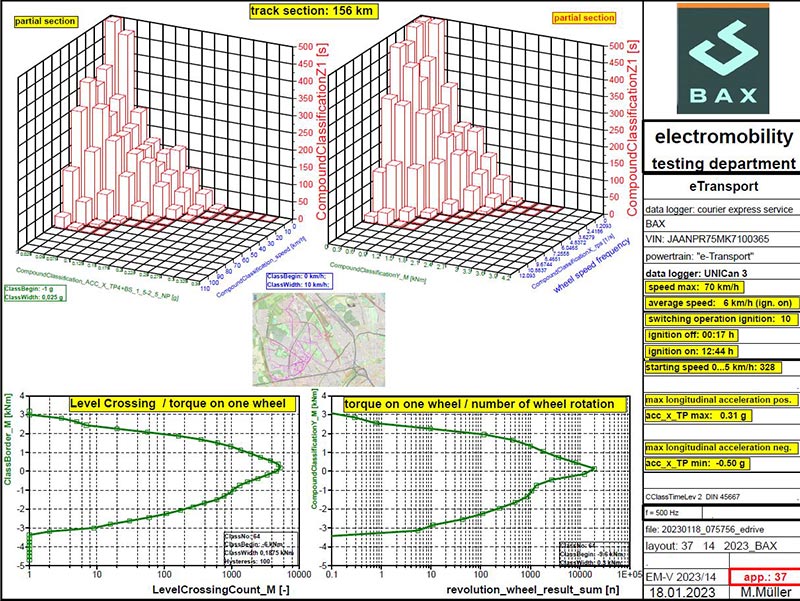

BPW Bergische Achsen Kommanditgesellschaft, a global supplier to the commercial vehicle industry and mobility service provider to the transport and logistics industry, therefore wanted to develop a coaxial drivetrain for use in an electrified truck. To do this, they first needed so-called "design collectives" to design the components. These contain load data from which conclusions can be drawn as to how the vehicle must be designed for its intended purpose.

Measurement Task

Recording of measurement data from different data sources and measurement technology from different manufacturers.

Technically sophisticated innovation

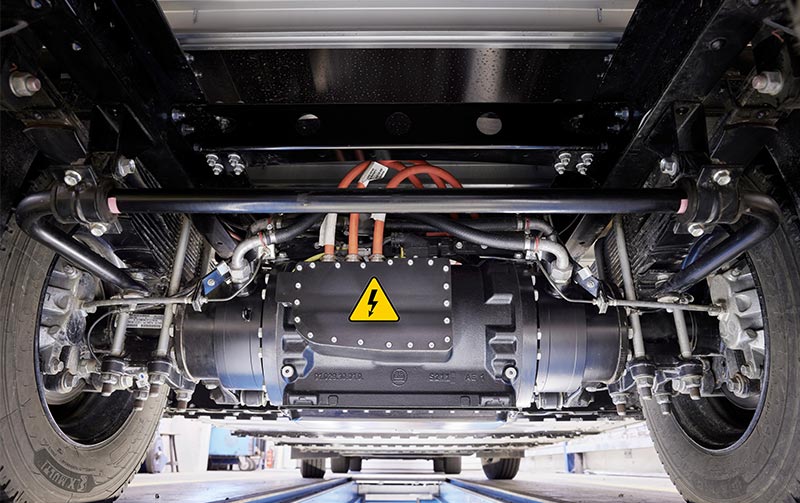

The electric powertrain that was to be developed needed to have a compact package design so that it could be installed on existing commercial vehicles as well as being fitted as original equipment. The coaxial e-axle in a truck was an innovative drive solution, so one of the challenges was that there were hardly any existing reference values.

To implement the project in a time and cost-efficient manner, as many tests as possible were performed simultaneously. For this purpose, a complete system was put together using measurement technology from various manufacturers. As all signals converged in the data logger used, it was particularly important to work with a device that has open interfaces for use with other measurement technology.

"Compiling a complete system of this kind individually for the respective measurement task requires a great deal of effort, as values from a wide variety of data sources have to be brought together. This gave rise to the following main questions: How do you integrate different measurement systems into a reliably functioning overall system and does it provide the data that is required?"

Udo Johannkemper, Support at CSM GmbH

Heterogeneous measurement setup - homogeneous results

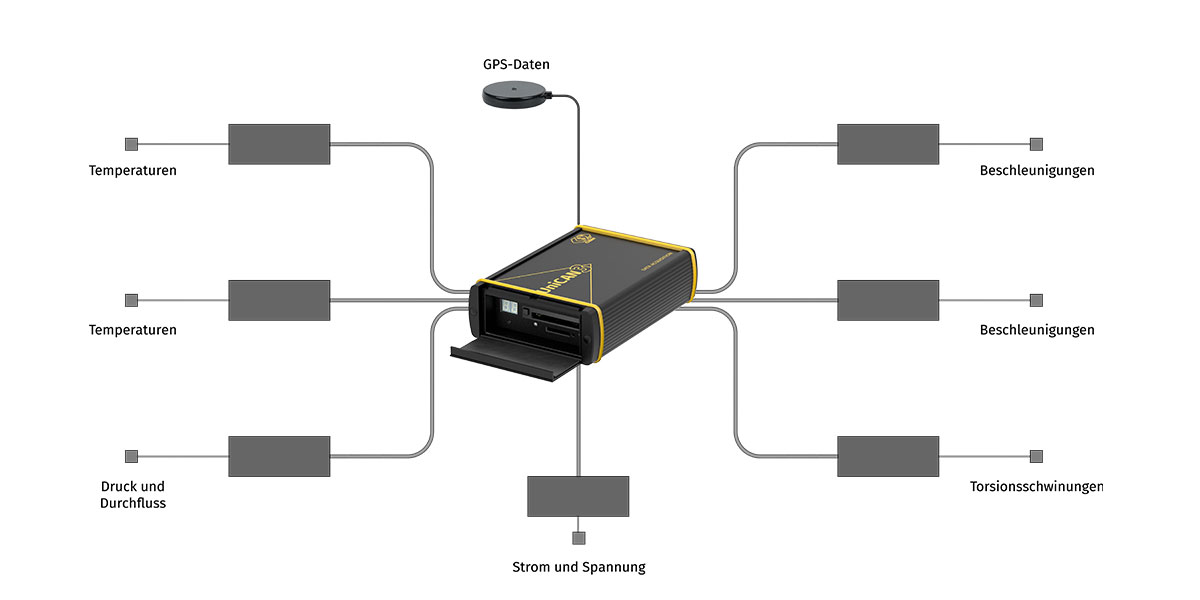

Based on the measurement data collected, the next step was to build the first prototypes of the coaxial e-truck for further tests - again using the robust UniCAN 3 data loggers from CSM. In two prototypes, which were used for further measurements on the test track and in road tests, the following measured variables, among others, were recorded:

- Accelerations, for example on the drive axle and chassis,

- Torsional vibrations on the drive shafts,

- Current and voltage from the electric powertrain,

- Temperatures throughout the vehicle,

- Pressure and flow rate in the cooling systems,

- GPS data.

When setting up a complex measurement setup consisting of components from different manufacturers, there are always challenges, such as changing signal structures or the subsequent integration of additional hardware. A flexible, adaptable system that made it easy to implement these changes improved the processes. The ability to adapt the measurement task at short notice via mobile connections also helped to ensure that the tight project schedule could be adhered to.

The CSM support team assisted with the implementation of the correct configuration of the measurement technology.

"The first-time consultation by CSM and the excellent support during the project were worth their weight in gold! Together, the various measurement systems were brought together, among other things. This meant that measurement data could already be used for validation in pre-development, for the prototypes and later also in field use."

Matthias Müller, Team Lead Road Test - Electromobility & Innercity Solutions at BPW Bergische Achsen KG.

Many years of experience used

The easily adaptable and durable data loggers from CSM could be used in all test phases and environments and configured according to the respective requirements. CSM's support accompanied the project through the various stages and also helped to merge the heterogeneous measurement landscape - years of project experience in the implementation of UniCAN 3 in demanding test environments proved beneficial here and also helped with the implementation of this solution for an e-truck.

More information

Related Products

Related Hardware

UniCAN 3 ETH Data Logger

Data logger for mobile applications with Ethernet interface

The UniCAN 3 ETH is a compact and robust data logger for the acquisition of data from various sources: With the Ethernet interface, nine CAN interfaces, digital inputs and outputs and numerous data transmission options, it can be used flexibly in any measurement task.

UniCAN 3 Data Logger

The data logger for mobile applications

With up to 12 CAN bus interfaces, freely configurable digital inputs and outputs, Wake-on-CAN, LAN, WLAN - When developing the UniCAN 3 data logger, numerous requirements from state-of-the-art vehicle development were taken into account.

Related Software

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.

CSMuniconf is the comprehensive software package for the configuration and management of the UniCAN 3 data loggers.

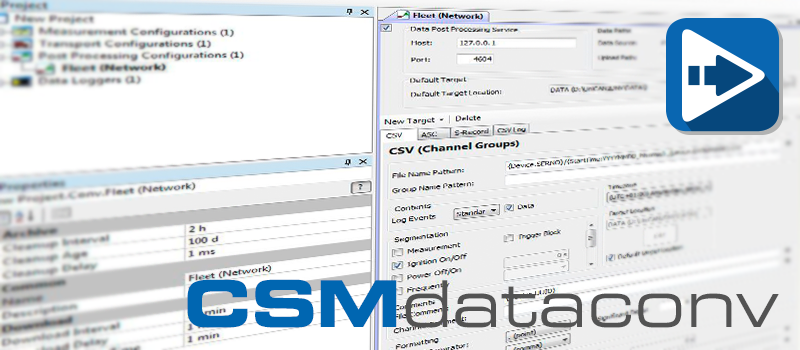

The server-based software CSMdataconv has been developed for the automatic processing and conversion of recorded measurement data.

Home

Home