Powertrain Validation in Forklifts

Validation testing is often needed when extensive design updates are made to the vehicle system. In these cases, all important vehicle parameters are tested under a wide range of operating conditions. The following example shows how such tests are performed on forklifts that incorporated new engine options.

Background

Vehicle manufacturers are constantly developing their products in order to offer the benefits of the latest innovations to their customers. The forklift manufacturer, Linde Material Handling, integrated new gas and diesel engines into the latest generation of forklifts for load capacities up to 2,000 kg and up to 5,000 kg. The necessary design adjustments for the engine integration and subsequent functional validation were contracted to the engineering service provider EDAG Engineering.

Fot the integration of the new enginges, changes had to be made to the hose routing and the electrical system. The comprehensive functional validation of the overall system is intended to ensure that the requirements for type approval (ECE homologation) are met. Without a successful verification, approval for production of the new generation of forklifts will not be granted.

Measurement task

Measurement of temperature, pressure, flow rate, current and voltage, for type approval after successful engine integration.

Challenge

In order to validate the performance of the system, numerous tests are carried out under a wide range of conditions, such as in a climatic chamber, at high altitude in the Alps, and also on the EDAG test track. Various performance characteristics were measured:

- pressures in the fuel and cooling systems

- currents and voltages of the battery and the starter

- flow rates in the cooling circuit

- temperatures at numerous locations throughout the engine compartment

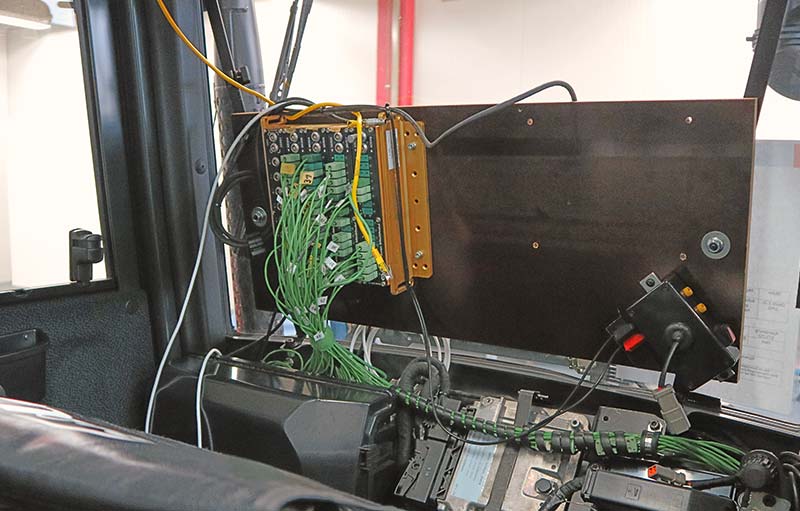

The EDAG team needed a measurement system that was flexible and scalable in multiple ways. Due to the large number and different types of tests to be performed, the measurement system had to be capable of being rapidly moved and re-used from one test to another. In addition, the measurement technology needed to be robust and compact in order to be installed within the limited space available in a forklift.

The system needed to obtain data from ECUs simultaneously via the CAN bus.

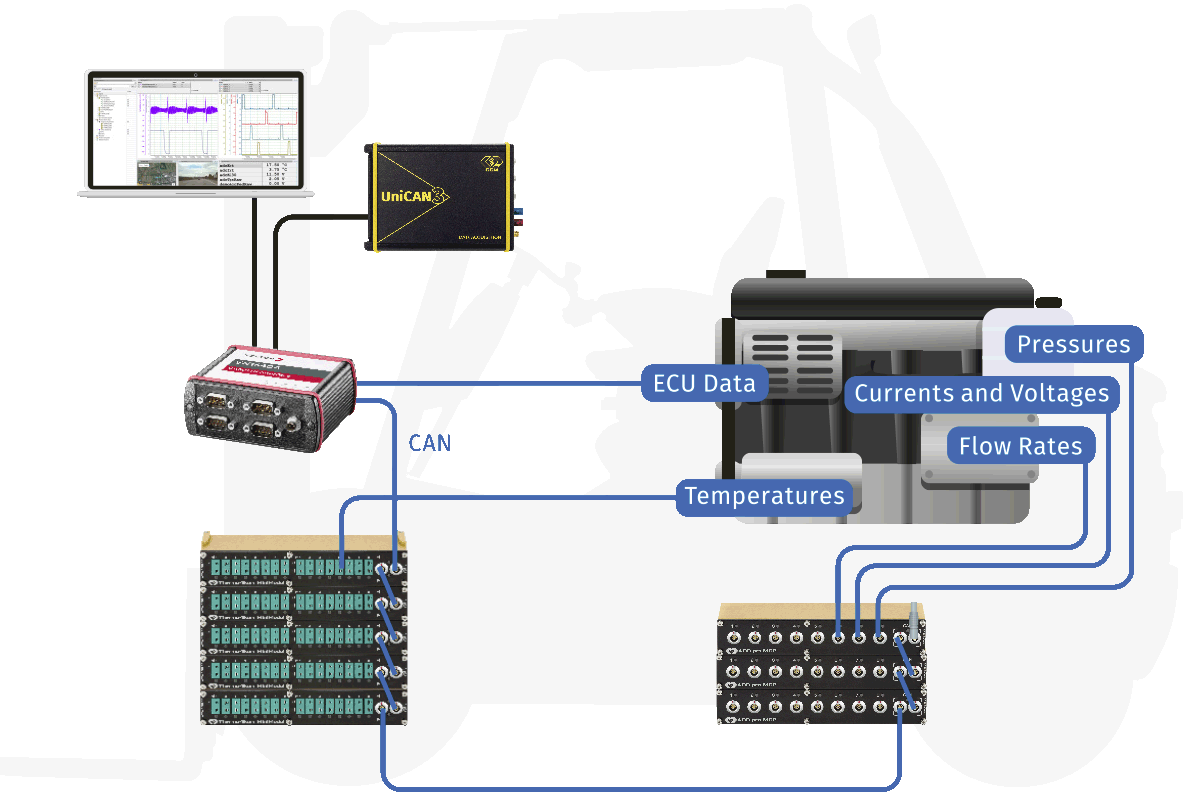

The CSM-Solution

- AD8 pro MC2

Acquisition of signals from standard sensors. - Temperatures

Measurement with K-type thermocouples - Standard Sensors

Measurement of flow rates, pressures as well as currents and voltages - TH16 pro

Easy connection of thermocouples - Vector Network-Interface

Time-synchronous acquisition of data from vehicle ECUs - CANape

Visualization of the measured values in real time - UniCAN 3

Recording of the measured values for subsequent analysis

- Suitable standard sensors are used to measure pressures, flow rates, currents and voltages. The output signals are acquired by AD8 pro MC2 measurement modules. These also supply the sensors with the required excitation voltage.

- K-type thermocouples acquire the temperature values at the relevant points in the engine compartment. The temperature measurement modules TH16 pro record the temperature data. With their internal cold junction compensation these measurement modules offer high accuracy over the entire temperature range and thus ensure very accurate measuring results.

- Using a Vector Informatik Network Interface VN1640, additional data from the ECUs is acquired synchronously.

- A data logger UniCAN 3 is used to record the collected data for subsequent analysis.

- The measured values are checked directly on a tablet using the Vector Informatik software CANape.

Benefits

With the Vector-CSM measurement system, functional verification can be carried out quickly and easily after new engine integration. An additional advantage is the simple integration of data from the ECUs.

We particularly liked the compact size and flexibility of the measurement technology products from CSM, which allows for easy scalability. It is also very helpful for us that the modules can be networked via the CAN bus and are easily integrated into the Vector Informatik software that we use.

Thomas Schenk - Team Leader GFA - NVH - Measurement Technology, EDAG Engineering GmbH

We would like to thank the EDAG team for the good cooperation in this project.

Featured Products

Related Hardware

CAN AD MiniModules

Allround measurement modules for sensors with analog voltage outputs

CSM’s AD MiniModules of the AD CAN MM (MiniModule)-Series offer a wide range of applications for measuring analogue signals (voltage, current, pressure, flow rate, etc.).

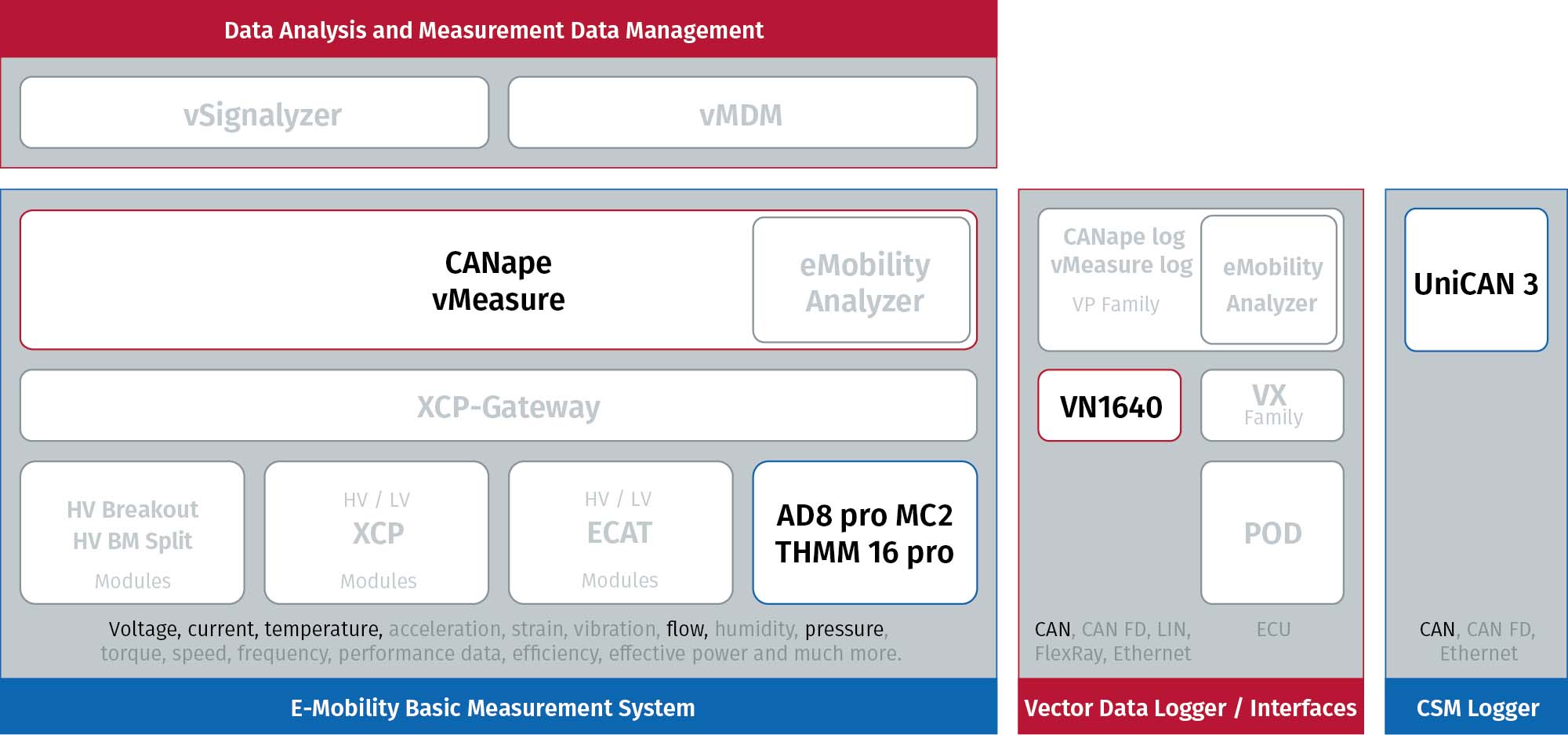

The Vector CSM E-Mobility Measurement System

The measurement system for the development of electric mobility

CAN TH MiniModules

Temperature measurements with K-, J- and T-type thermocouples

CSM’s Thermo MiniModules allow precise distributed temperature measurements with K-, J- and T-type thermocouples: ideal for measurements in the powertrain, on HVAC (Heating, Ventilation, and Air-Conditioning) components, in the vehicle interior, the powertrain development and many more.

UniCAN 3 Data Logger

The data logger for mobile applications

With up to 12 CAN bus interfaces, freely configurable digital inputs and outputs, Wake-on-CAN, LAN, WLAN - When developing the UniCAN 3 data logger, numerous requirements from state-of-the-art vehicle development were taken into account.

Related Software

vMeasure

Reliably Solving Complex Measurement Tasks

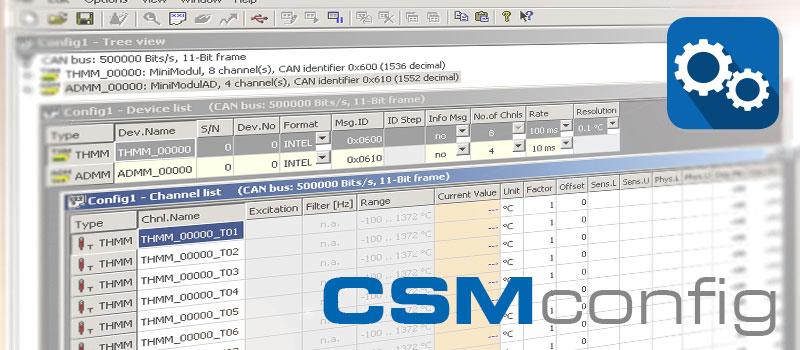

vMeasure is a subset of CANape focused on measurement. It is an easy-to-use software tool for the acquisition and analysis of measurement data that can be used in combination with all CAN- and EtherCAT®-based CSM measurement modules. CSMconfig was integrated directly to ensure swift configuration.

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.

Home

Home Newsletter

Newsletter