Measurement Technology in the Formula E

Motorsport places the toughest demands on man and machine; and also on the measurement technology that is indispensable for development. ABT Sportsline, together with Audi and Schaeffler, has used CSM's measurement technology in Formula E to obtain precise data during the development and testing of the racing cars. Find out in the following application report where CSM measurement technology was used.

Background

After an extremely successful 2014/2015 season, ABT Sportsline used CSM measurement technology for the development of the purely electrically driven racing cars during all official test drives. Thereby different measurement variables had to be recorded.

Measurement task

Measurement of accelerations, strains, flow rates and temperatures, for the further development of a Formula E racing car.

Challenge

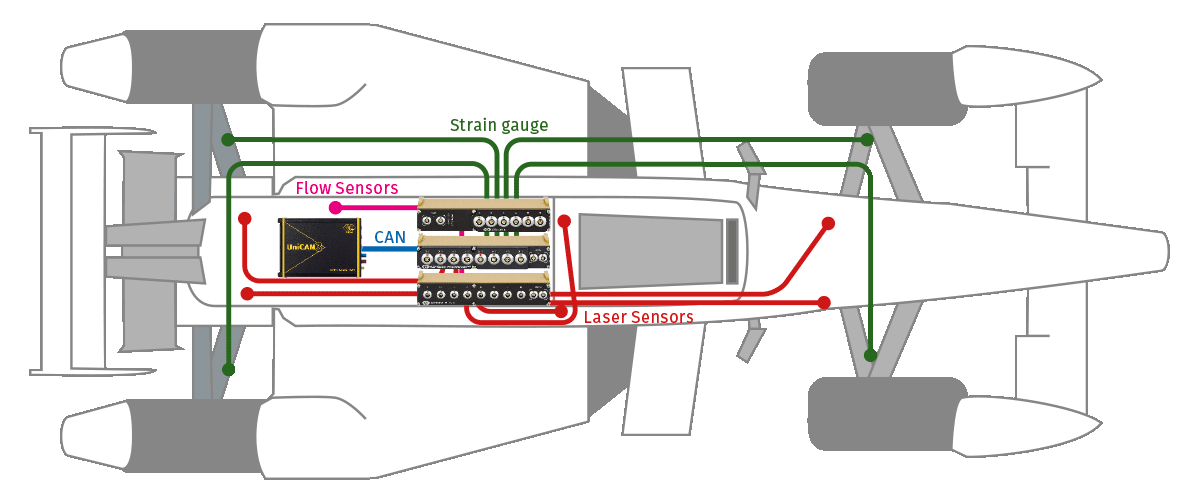

The available space for measurement modules in racing cars was naturally limited and the measurement technology had to withstand harsh conditions (for example, high temperatures, moisture from splash water and centrifugal forces). Furthermore, a wide variety of measurement variables had to be recorded synchronously: accelerations, strains, flow rates and temperatures. These variables could vary from test drive to test drive and the conversion should be as simple as possible.

The CSM Measurement Solution

- Mechanical load

Strains and compressions were measured at the wheel suspension - Acceleration

Accelerations were additionally measured at the axes - Distances

The distances to the ground were measured with laser sensors - Temperatures

The temperatures were recorded in the engine compartment and on the battery - CAN PTMM

Acquisition of temperature data from PT100 or PT1000 sensors - CAN AD8 pro MC2

Simple use of standard sensors for measuring accelerations, distances and flow rates - CAN STG6 BK10

Strain measurements with strain gauges - UNICAN data logger

Recording of the measurement data in the test bench - Flow rates

In the cooling system the flow rates were measured

- Several measurement modules CAN AD8 pro MC2 were used for the desired measurements. This allows standard sensors to be easily applied and a large number of the desired measurement variables to be acquired.

- These measurement modules were supplemented by modules for measurement with strain gauges CAN STG6 BK10 and temperatures with PT temperature sensors CAN PTMM 4.

- During the test drive, all the measurement data collected was recorded via the vehicle's own control unit.

- In the test bench a UniCAN data logger was used for data recording.

Benefits

The advantages of this measurement system were especially the easy adaptation of the system by adding further measurement modules and sensors. Thus the system could be specifically adapted for individual tests by integrating new sensors without having to change existing cables and software.

We thank the team of ABT Sportsline for this exciting project and the good cooperation.

All pictures with kind permission of ABT Sportsline GmbH.

Featured Products

Related Hardware

CAN STG6 MiniModule

Measurement of mechanical strain in any environment

Precise measurement of mechanical strain, directly at the point of application of the strain gauge: realized via the CAN-based measurement module STG6 BK10 with six strain gauge inputs for quarter-, half- and full bridges.

CAN PT evo

Temperature measurements with PT100 and PT1000 RTD sensors

CSM offers these modules for temperature measurements with increased accuracy requirements compared to thermocouples. PT evo modules allow high-precision temperature measurements with either PT100 or PT1000 RTD elements.

CAN AD MiniModules

Allround measurement modules for sensors with analog voltage outputs

CSM’s AD MiniModules of the AD CAN MM (MiniModule)-Series offer a wide range of applications for measuring analogue signals (voltage, current, pressure, flow rate, etc.).

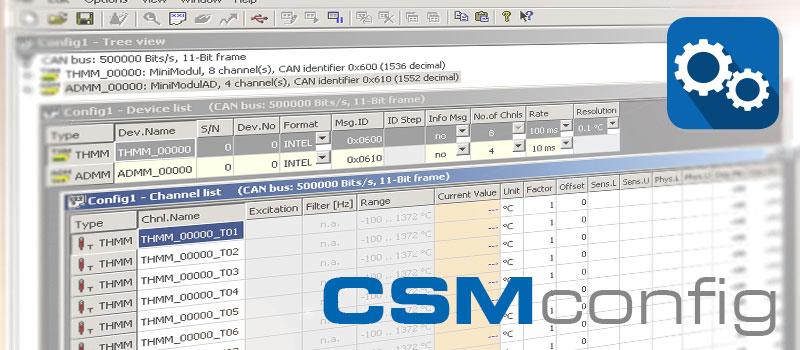

Related Software

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.

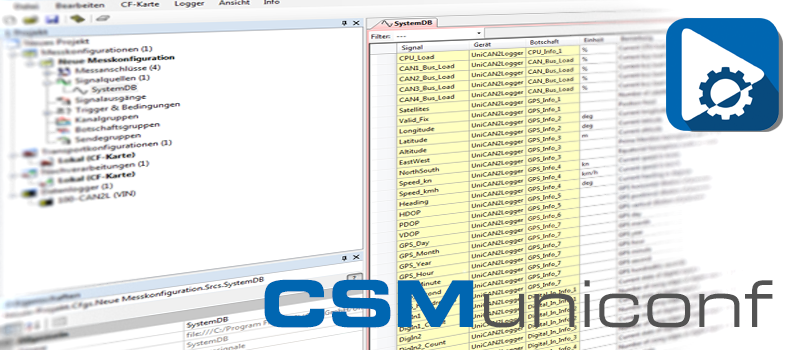

CSMuniconf is the comprehensive software package for the configuration and management of the UniCAN 3 data loggers.

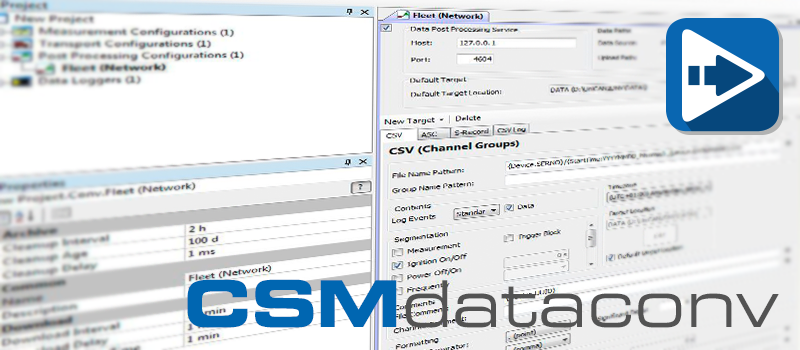

The server-based software CSMdataconv has been developed for the automatic processing and conversion of recorded measurement data.

Home

Home