UniCAN 3 Data Logger

Flexible data recording wanted: Fuel cell trucks under endurance test

The development of hydrogen-powered trucks, whose electric motors are driven by electricity from fuel cells, initially required numerous tests on test benches. Various driving tests were then carried out in pre-series fleet tests. A data logger from CSM was installed to reliably record the results during both test situations: The UniCAN 3 was particularly impressive due to its configurability via remote access.

Green powertrains for trucks

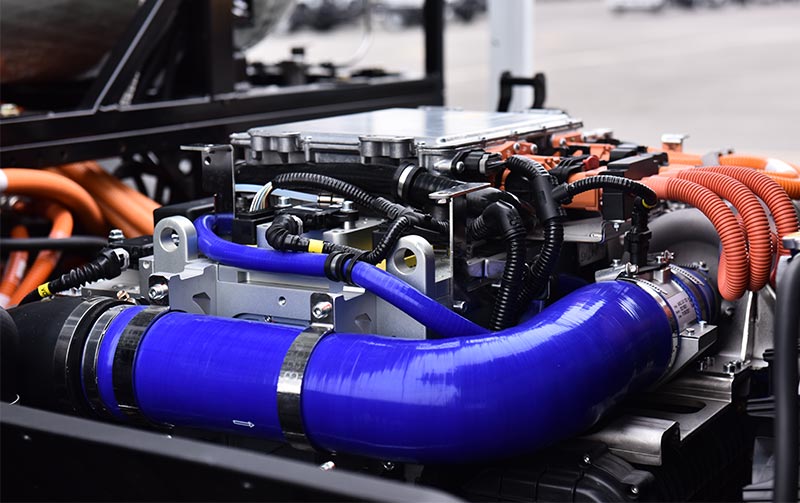

In addition to purely battery-electric vehicles, alternative concepts are also becoming relevant in the commercial vehicle sector. One approach: powering trucks with fuel cells, i.e. generating electrical energy from the chemical reaction with hydrogen directly in the vehicle. The battery installed in the drivetrain is significantly smaller and lighter, as it does not serve as the primary energy source, but only as an intermediate storage unit. Robert Bosch GmbH, the world's largest automotive supplier, manufactures mobile fuel cell systems for this purpose, so-called “Fuel Cell Power Modules”, which are being tested by various vehicle manufacturers worldwide.

Measurement Task

Recording of CAN bus data from control units and additional measurement data.

Data recording for long-term analysis

During extensive testing at both the bench and in fleets, measurement data from the control units of the mobile fuel cells and other measured variables were recorded in various situations. The aim was to record large amounts of data over a long period of time, and the resulting findings were able to help detect faults at an early stage. This will also accelerate vehicle development in this area in the future.

In the test vehicle

To ensure that the data obtained was comparable, the measurement technology used had to be suitable for both the test bench and for use in the test vehicles. Furthermore, during these iterative pre-series fleet tests, errors that were discovered during the first test runs were corrected immediately. However, this meant that the measurement and data recording requirements also changed repeatedly, as new test situations were checked again after the adjustment. The data logger configuration therefore had to be reconfigurable remotely worldwide based on the interim results of the measurements. This ensured that the changes could be made without the intervention of the test driver or removal of the data logger.

Space problems in the truck

The hardware conditions also played an important role: the data logger used had to be suitable for use in the test bench as well as for the road test. This requires a compact design and distributed use, as the device must be installed wherever space is available in the fuel cell power module. Even in a truck, there is only limited installation space for the fuel cell system. It was therefore important that the required hardware also had small dimensions. Thanks to its compact dimensions of approximately 109 × 45 × 158 millimeters, this was achieved despite the difficult conditions.

From test bench to road

To record the measurement data in the 30 test vehicles of the pre-series fleet - with up to 3,000 signals - the fuel cell systems with the UniCAN 3 data loggers were installed in the individual test trucks.

The UniCAN 3 recorded data from nine CAN sources: seven of these were CAN bus data from the control units of the fuel cell power modules. In addition, also via CAN, temperatures from the area around the mobile fuel cells were measured with thermocouples and THMM 16 pro Type K temperature measurement modules. Humidity was also measured in the air paths of the fuel cells using special sensors and AD pro mini modules via CAN.

“As we have already had very good experiences with the data loggers and associated software solutions from CSM in the past, the UniCAN 3 devices were once again our first choice. They represent a flexible overall system that is ideally suited to our requirements. In addition, the technically competent support with short response times is also of decisive importance to us for the reliable running of our project.”

Paul Meyer, Development engineer at Robert Bosch GmbH

The UniCAN 3 - an all-rounder

A flexible data logger is required if the same measurement technology is to be used to record data both on the test bench and in test vehicles. The compact dimensions ensure that the UniCAN 3 can be easily integrated into both test environments, while data transmission and configuration adjustments can be carried out remotely via the integrated modem. This avoids the need to remove the data logger and thus saves time and money, especially in the case of measurement tasks that require constant adjustments.

More information

Related Products

Related Hardware

CAN TH MiniModules

Temperature measurements with K-, J- and T-type thermocouples

CSM’s Thermo MiniModules allow precise distributed temperature measurements with K-, J- and T-type thermocouples: ideal for measurements in the powertrain, on HVAC (Heating, Ventilation, and Air-Conditioning) components, in the vehicle interior, the powertrain development and many more.

UniCAN 3 Data Logger

The data logger for mobile applications

With up to 12 CAN bus interfaces, freely configurable digital inputs and outputs, Wake-on-CAN, LAN, WLAN - When developing the UniCAN 3 data logger, numerous requirements from state-of-the-art vehicle development were taken into account.

Related Software

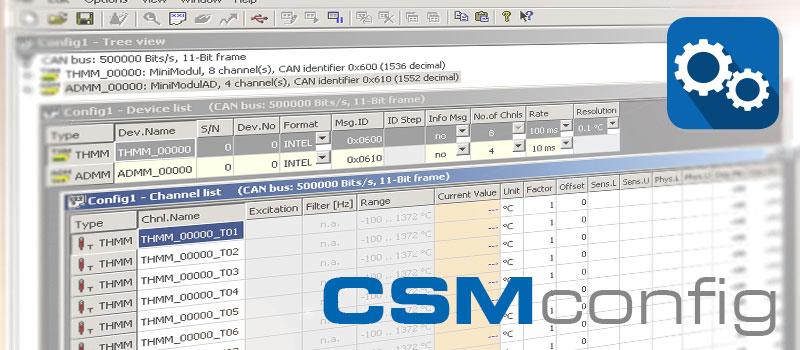

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.

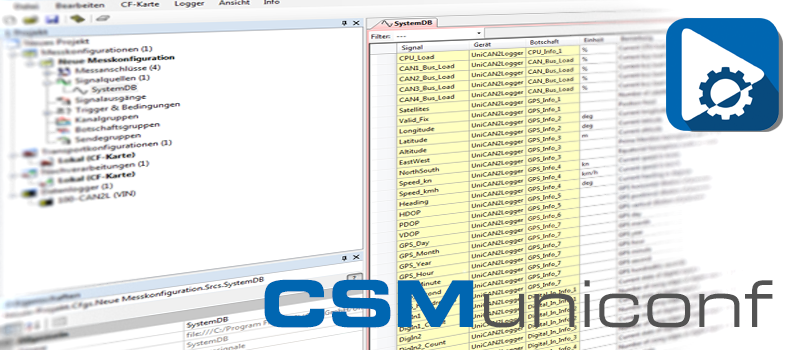

CSMuniconf is the comprehensive software package for the configuration and management of the UniCAN 3 data loggers.

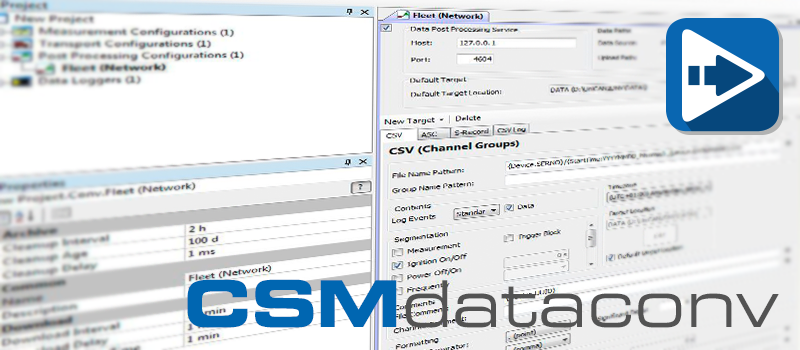

The server-based software CSMdataconv has been developed for the automatic processing and conversion of recorded measurement data.

Home

Home