The world's first digital temperature measurement system for faster battery development

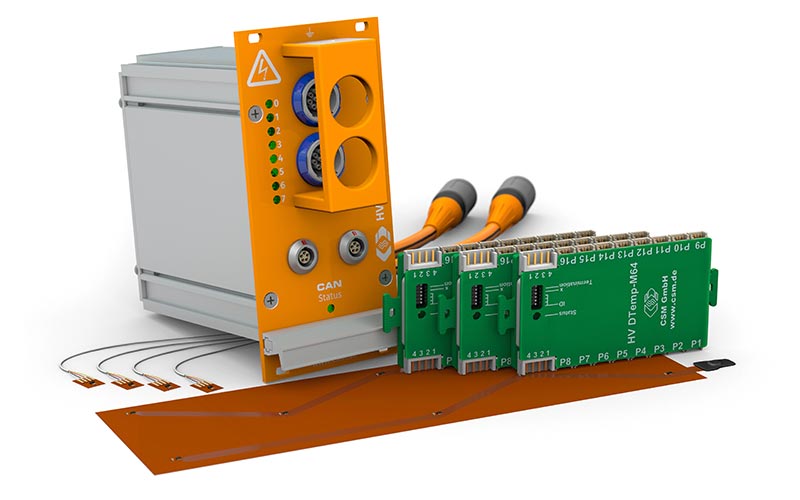

CSM presents the digital temperature measurement system HV DTemp for the precise and interference-free acquisition of up to 512 temperature measurement points in a high-voltage module with only one connection cable to the central unit HV DTemp-P. This allows the analysis of the thermal behaviour of high-voltage batteries and the verification of their temperature models to be carried out quickly, efficiently and in a particularly space-saving manner down to cell level.

High requirements for temperature measurements in a high voltage battery

High-voltage batteries are an essential element for electro-mobility. Their performance and thermal behaviour define charging concepts and driving characteristics. They are thoroughly verified in terms of their thermal behaviour. Hundreds of temperature sensors must be positioned as precisely as possible for this purpose and must not impair the battery's behaviour. The temperature sensors must be miniaturized, highly accurate, robust and immune to interference so that they can be used between cells and modules in the high-voltage battery. Access to the high-voltage battery must be extremely space-saving and high-voltage safe.

CSM's new HV DTemp digital temperature measurement system (patent pending) has been specially developed to meet these requirements.

Individual sensor arrangement with flex print

The exact knowledge of the temperature distribution and its change due to different load and charge states down to the cell level allows the optimization of battery systems and their temperature models. The HV DTemp IC (Integrated circuit) Sensors can be arranged in different variants to suit the respective measurement point. As single sensors, the IC sensors can be connected directly to a controller. As a sensor assembly, four sensors can either be daisy chained or connected via a small distribution board. Finally, the sensors can be precisely positioned as an ultra-thin flexible circuit and connected via strip lines.

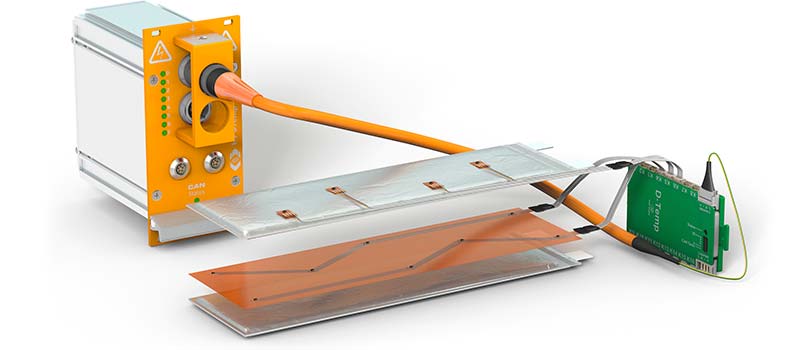

The IC sensor arrangement can be customized to meet the exact requirements of temperature testing within the high-voltage battery, within individual modules on components or connection rails. This allows the highly accurate measurement of temperature distribution, temperature paths, temperature profiles or hot spot areas. Due to the individual, reproducible sensor arrangement as well as the sensor positioning as ultra-thin flexible circuit, the assembly of test and prototype batteries is considerably accelerated and simplified.

Connection with only one high-voltage safe measurement cable

To date, analog and thus interference-sensitive signal cables had to be led out of the high-voltage range of the battery, corresponding to the number of temperature sensors. The breakthrough of already 100 signal cables out of the battery housing to the measurement modules has so far made precise investigations considerably more difficult and in some cases even impossible.

With the new HV DTemp digital temperature measurement system, up to 64 IC temperature sensors within the test battery are connected via a HV DTemp-M Controller. Up to eight HV DTemp-M Controllers can be cascaded in one battery. This allows the connection of up to 512 IC temperature sensors to the central unit HV DTemp-P with only one high voltage safe measurement cable.

Interference-free and precise temperature measurements

The HV DT IC Sensors are clearly addressed via the Controllers and configured via the central unit. Data output is via CAN bus in Free Running Mode. Each IC temperature sensor generates directly digitized measured values, i.e. there is no risk of acquiring incorrect measured values due to disturbances in the signal cables. The measurement accuracy is up to 0.1 °C with a 16-bit resolution. The operating temperature range is from -40°C to +125°C.

With the new digital temperature measurement system HV DTemp, CSM enables a faster and more efficient development of batteries and energy storage devices.

Home

Home Newsletter

Newsletter