Fast Measurements in High-Voltage Environments

Fields of Application, Outstanding Properties, Requirements

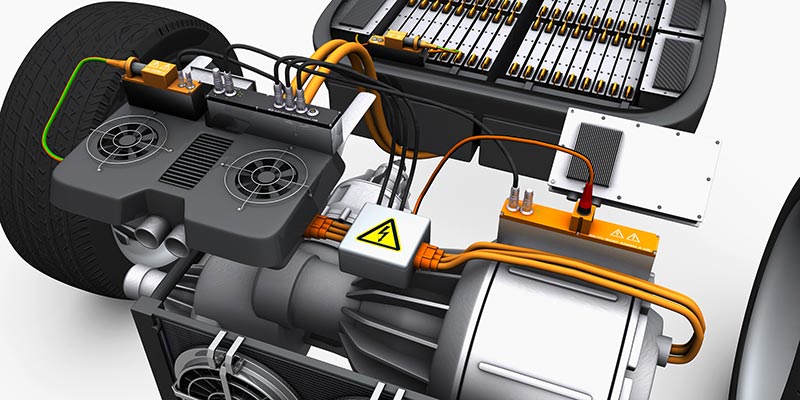

Modern electric vehicle technology puts new requirements to a high-voltage on-board system and the components connected to it. The inverter technology applied in the powertrain uses very fast switching frequencies and it is their impact on the on-board power supply which needs to be analysed.

The voltage and current flows prevailing in high-voltage environments are decisive for dimensioning its electric components. Transient voltage and current peaks can occur during operation, usually with a duration of only a few milli- or microseconds. Despite their short duration, these voltage and current peaks may seriously damage electric components since they are often significantly higher than the permanently applied voltages and currents. It is thus essential that measurements allow the visualization of those peaks. Only the sampling with high measurement data rates enables their detection.

Measuring the actual voltage flows of all three phases at the inverter during test drives appears as an obvious measurement task. The optimization of electric motors and inverters is another field of application for fast measurements. Besides the acquisition of peaks in voltage curves, it is the effective value of the modulated sinusoidal AC voltage, which is of high interest. The inverter operates at frequencies in the double-digit kHz range creating a chopped voltage curve. The conversion into an effective value thus requires a high oversampling rate.

Calculating the effective value of a voltage becomes especially relevant if the effective current value is available at the same time. As a rule, sampling rates can be lower here since the current curve does not change very rapidly. Multiplying both values at exactly the same time provides the curve of the effective power.

It’s the synchronous high-speed data acquisition via EtherCAT® protocol using robust decentralised measurement technology that provides entirely new options for data analysis in road testing. Due to the synchronicity of the measurement data, the individual points of measurement of all voltages and currents are on the same time axis. High precision power calculations are possible due to the high sampling rate of voltage and current.

Even measurements on high-voltage components outside the vehicle such as charging stations or inverters and their interaction with the on-board power supply may be important. The question arises, for example, in how far disturbances in the electric grid may have a negative impact on the on-board power supply and vice versa.

As for the vehicle itself, measurements on high-voltage consumers, e.g. air condition, steering and brakes, are performed. More and more components will be electrified in future vehicles and an increasing number of consumers will be supplied by the on-board high-voltage power system. Here, too, possible impacts on the on-board power supply need to be evaluated.

Consumers are normally clocked, which means they are driven and controlled via pulse-width modulation (PWM). What is also important is the visualization of the effective power in parallel or synchronous to other measured quantities such as braking pressures, yaw rates, etc. Visualizing these processes requires three-digit kHz measurement data rates. Low-frequency sampling is not sufficient here.

The challenge in terms of measurement technology is to pick the suitable devices for data acquisition. CSM GmbH offers a wide range of measurement modules designed to be used in high-voltage environments. The bandwidth of the proven CAN-based measurement technology is insufficient for handling these tasks.

With the CSM ECAT measurement modules for high-voltage applications, measurement data rates up to 1 MHz per channel are available. CSM provides measurement module HV AD4 XW1000 designed for continuous voltage measurement up to 1,000 V for this purpose. In order to be able to record transient overvoltages, the measurement ranges of the analog inputs are dimensioned for ±2,000 V.

Recording the current curve requires a suitable sensor. It is recommended to use Hall-Effect-based sensors as this type of current transducer allows high threshold frequencies. Using this type of sensor also provides the means to electrically isolate the measurement setup from the measurement equipment. To this aim, CSM developed the LEM Sensor Packages, designed to be used in combination with ECAT modules and delivered ready to be applied.

Data acquisition is performed with the new software tools vMeasure exp or proven and known programs such as CANape from Vector and INCA from ETAS. Additionally, ECU data can be recorded synchronously.

All high-voltage measurement modules undergo a type approval and a routine test according to safety standard EN 61010. This provides best possible safety for the user.

Home

Home Newsletter

Newsletter