Menu

- News

- Fields of Application

- Products

- Support

- Downloads

- Company

- Contact

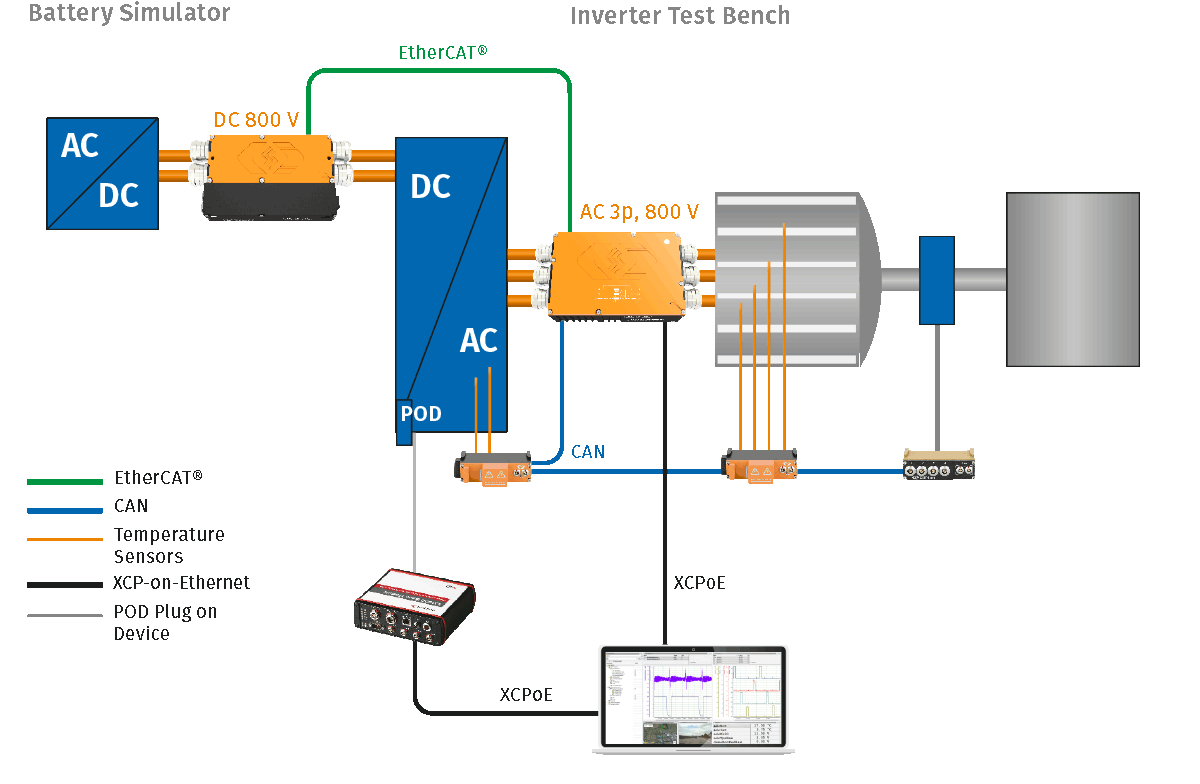

The optimal design of inverters is necessary for increasing the range per charge and performance of electric vehicles. The inverter is the link between the battery and the electric motor and plays an important part in the electric powertrain. This application example shows how power and efficiency calculations are performed on the inverter and how the measurement setup can easily be expanded for further measurements.

When converting DC from the battery into three-phase AC, which is used to regulate the three-phase electric motor, part of the energy is lost due to PWM switching performance and waste heat in the inverter. These losses must be kept as low as possible. The efficiency of the inverter is a suitable parameter to evaluate changes in design and software. Ideally, the efficiency of the inverter can be directly correlated with the efficiency of the associated electric motor.

Measurement task

Measurement of electrical input power and electrical output power for the calculation of the inverter efficiency.

To determine the inverter efficiency, the electrical input and output power must be measured synchronously and in a high-voltage safe manner. The measurement must be carried out with high data rates and phase accuracy in order to have suitable data for a precise calculation. At the same time, temperatures in the inverter must be measured in order to analyse the effects of thermal changes on the performance. If the efficiency of the electric motor is also to be calculated in parallel, the mechanical output power must also be measured.

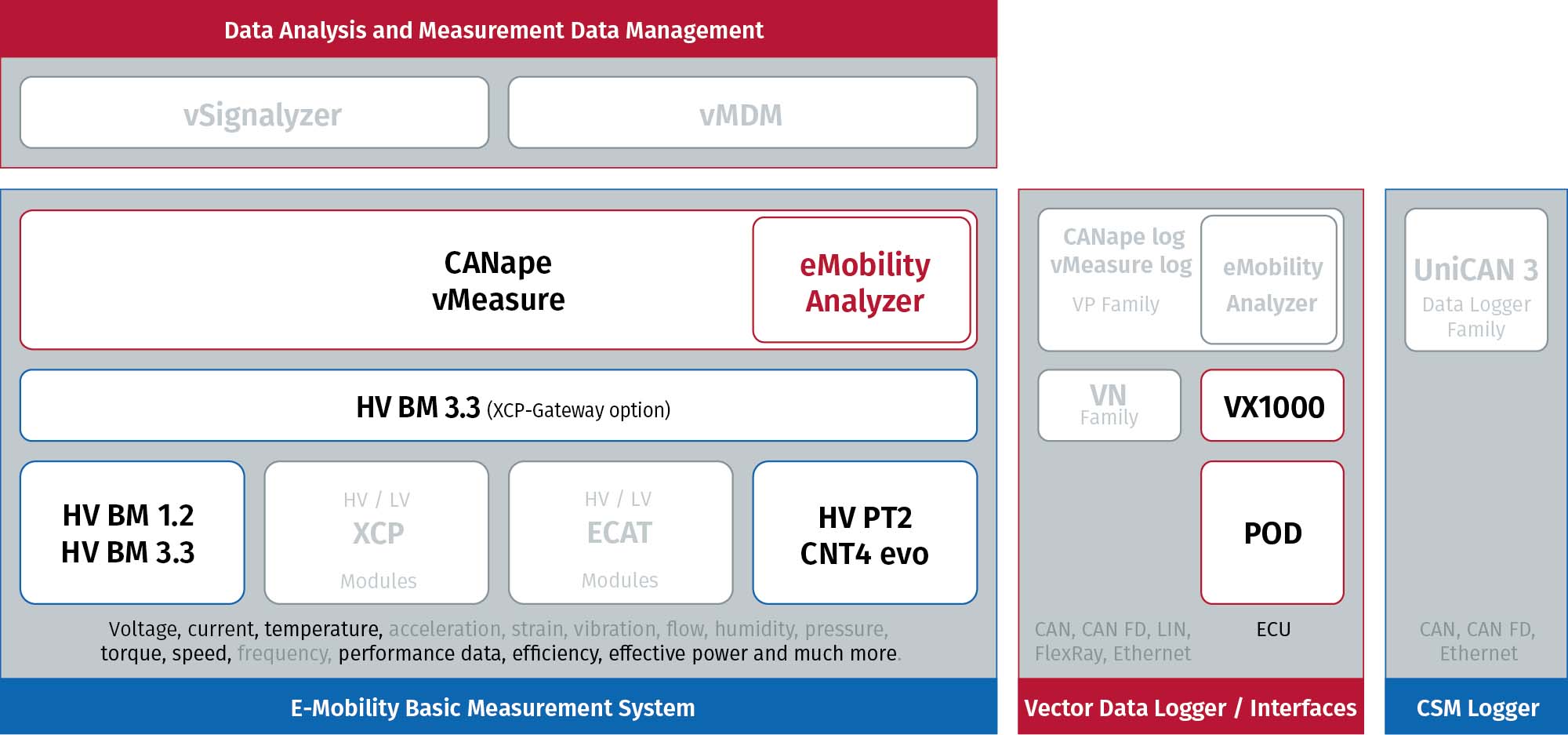

The solution for this measurement task is found in the perfectly harmonized Vector CSM E-Mobility Measurement System, which combines precise measurement modules and powerful software.

With the Vector CSM E-Mobility Measurement System, the calculation of the overall efficiency can be done in real time. Due to the robust and compact measurement modules, the measurement can be performed both on the test bench and in road tests. The test setup is shortened to a few components, which reduces the time required for the test setup and increases the quality of the measurement.

Furthermore, the Vector CSM E-Mobility Measurement System allows easy integration of additional measurement modules for further measurement variables, e.g. temperatures.

Safe temperature measurements with thermocouples on high-voltage components: the high-voltage-safe temperature measurement modules are specifically designed for the reliable acquisition of temperatures in electric and hybrid vehicles.

CSM's HV PT measurement modules allow precise temperature measurements with PT100 and PT1000 resistance sensors in a high-voltage environment.

The HV Breakout Modules (BM) Type 3.3 have been specially designed for safe and precise three-phase measurement in HV power cables. The inner conductor currents and outer conductor voltages are directly acquired and output via XCP-on-Ethernet.

The CNT evo is a high-precision measurement module designed for measuring frequencies, pulse widths, incremental displacement measurements, rotation angles, position measurement, event counting and period measurements.

The HV Breakout Modules (BM) Type 1.2 have been specially designed for safe and precise single-phase measurement in separated HV+ and HV- power cables. Inner conductor current and voltage are measured directly and the instantaneous power is calculated in the module.

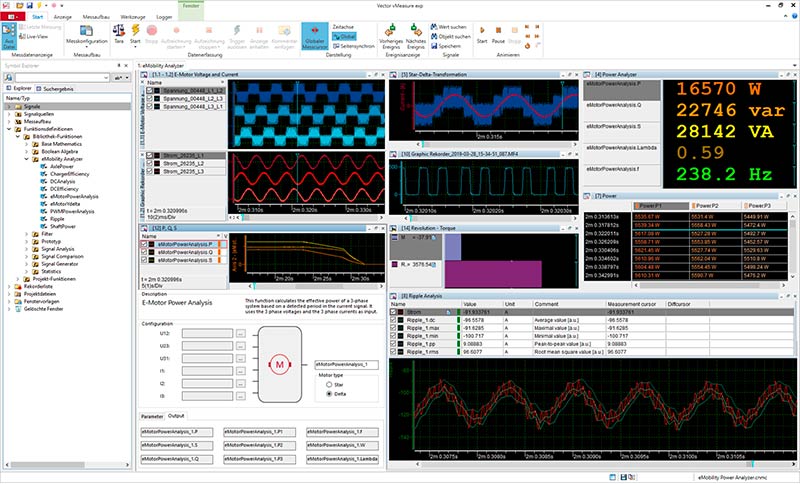

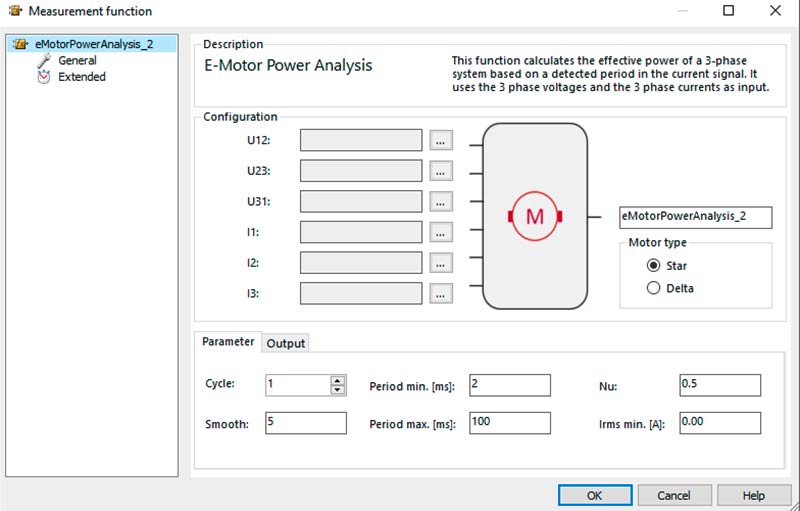

vMeasure, developed by Vector Informatik, is an easy-to-use software tool for the acquisition and analysis of measurement data that can be used in combination with all CAN- and EtherCAT®-based CSM measurement modules. CSMconfig was integrated directly to ensure swift configuration.

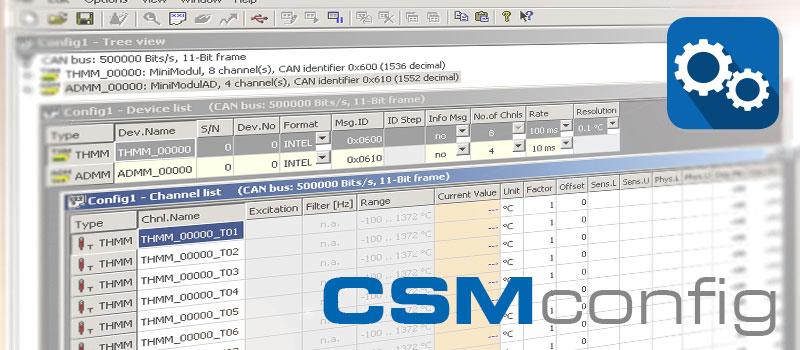

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.