Menu

- News

- Fields of Application

- Products

- Support

- Downloads

- Company

- Contact

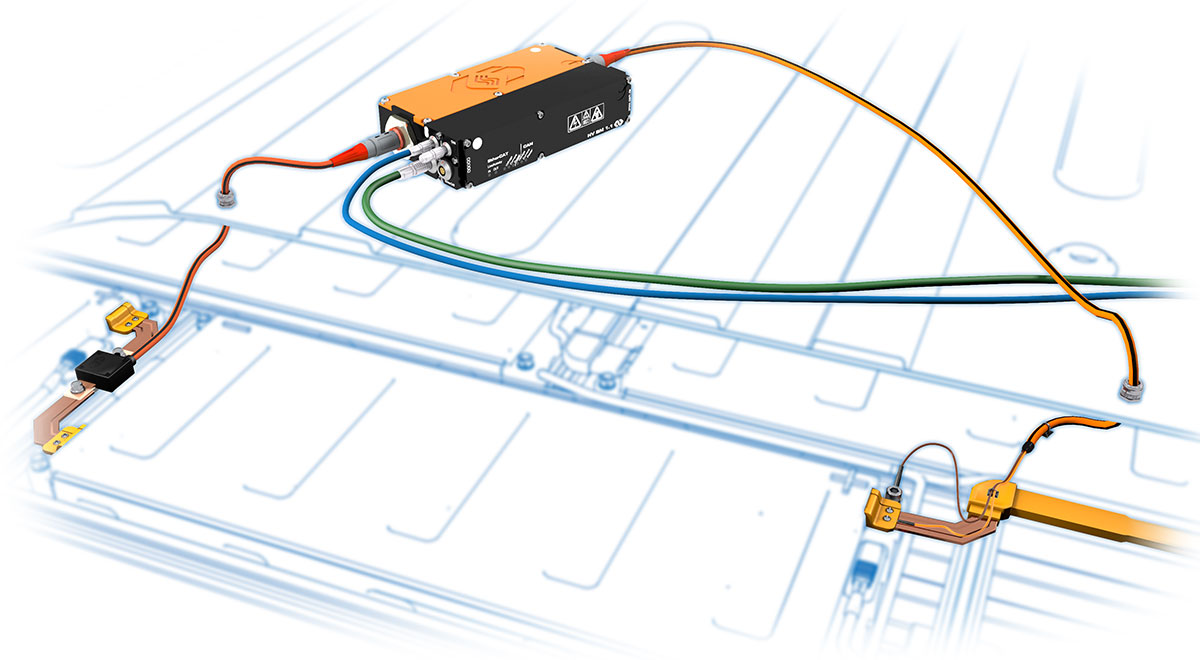

To save valuable space, components in the electric power train are becoming more compact and integrated. At the same time, this limits the space for installing measurement technology needed for current and voltage measurements in the busbars of integrated e-axles, inverters or HV batteries. Precise measurement results for testing, validation and verification are thus difficult to achieve. This example shows how high-frequency measurements can be carried out in busbars despite the confined space available.

Current flows and voltages in busbars must be measured in numerous components of electric and hybrid vehicles: In HV batteries, current and voltage measurements in the busbars are used to verify simulations for the design of the battery and the battery management system. In integrated e-axles, the measurements in the busbars between the inverter and the electric motor serve as a starting point for performance analyses.

In general, various measurement technology solutions are available. Measurement shunts are ideal for such applications due to their low susceptibility to interference and the possibility of direct installation in the busbar, which minimizes the space required.

Measurement Task

Acquisition of current, voltage and power in busbars, e.g. to analyze performances and verify simulations.

The measurement technology used must be small enough to be installed in the confined installation spaces and the busbars.

For precise measurements, a large measurement range should be covered, the measurement technology should be insensitive to interference and it should be possible to measure at high data rates.

Furthermore, the measurement technology must of course ensure HV safety for users and adjacent systems by means of suitable protective measures.

Current and voltage measurements in busbars can be easily implemented with HV BM Split Modules. Due to the split design of measurement modules and acquisition module, the measurement setup can be designed flexibly and measurements can also be taken at measurement points in very confined installation spaces. The measurement modules for current measurement (HV SBM_I - HV Split Breakout Modules) use the active shunt modules of the well-known HV Breakout Modules. These shunt modules consist of measurement shunt, temperature sensor and the sensor electronics and allow very precise measurements of currents with constant current intensity and also high-frequency current peaks.

Due to the very small design and the special features of the CSM shunt technology, currents and voltages can be measured very precisely even in busbars. The shunt-based measurement and the special sensor electronics minimize the influences of external fields (pseudo signals, hysteresis effects, system-related noise, characteristic curve shift or offset errors) and thus provide very accurate measurement results for further analyses.

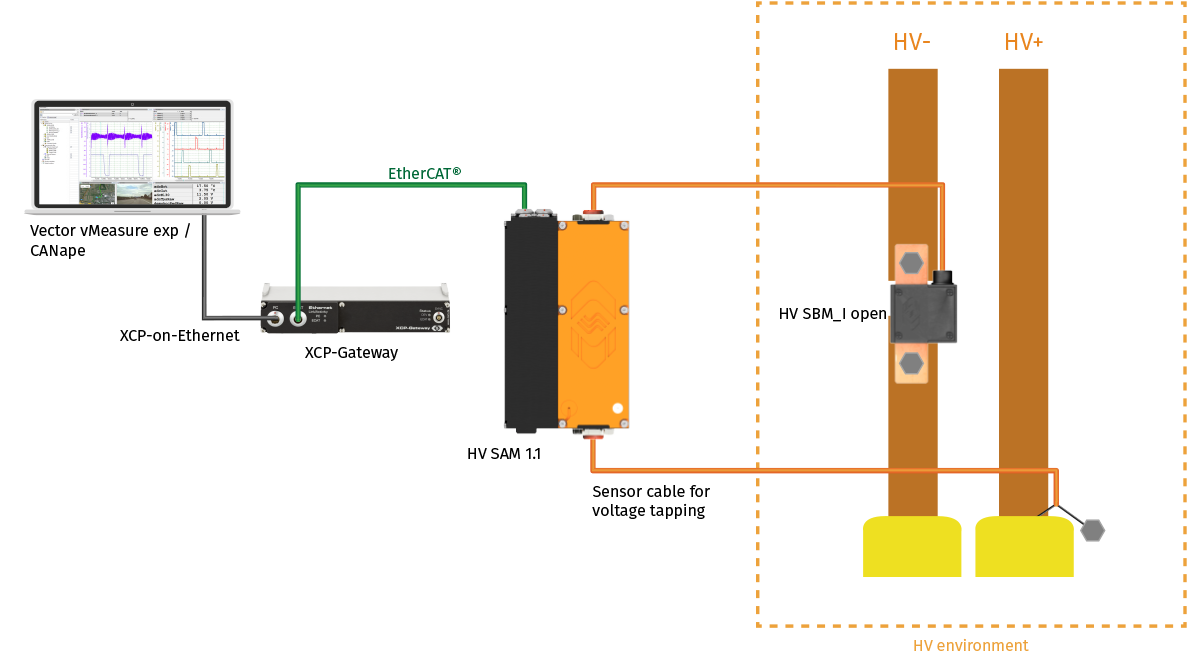

Performance data are also calculated directly in the HV SAM 1.1 measurement module. For more in-depth analyses in real time, further components from the Vector CSM E-Mobility Measurement System are used.

The HV BM Split Modules use the proven technology of the HV Breakout Modules for fast and precise measurement of internal conductor current, voltage and power even in confined spaces. HV BM Split Modules can be used to perform measurements in HV power cables or also on busbars.

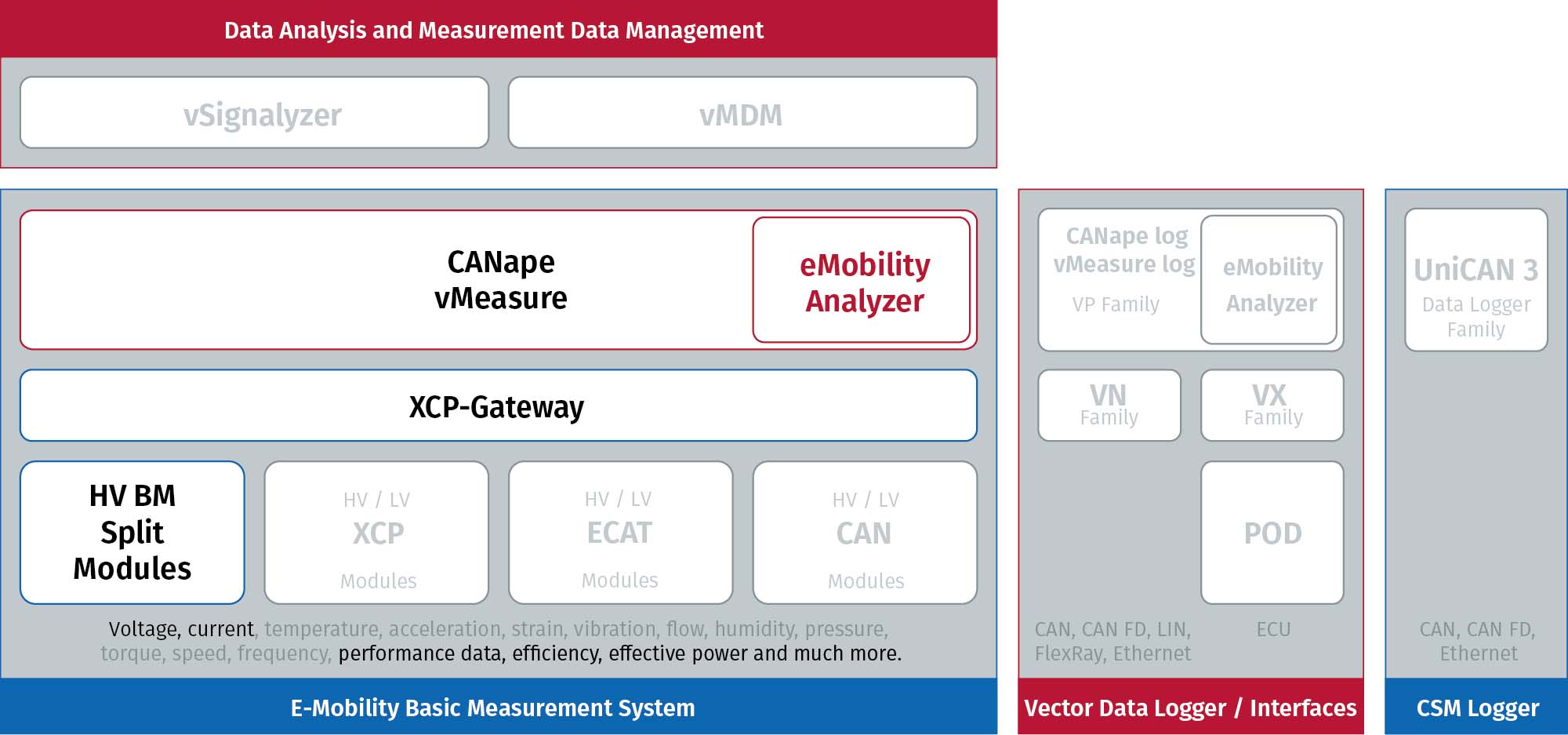

XCP-Gateway is the interface between the data acquisition software (e. g. vMeasure, CANape®, INCA®, Vision® ...) and the EtherCAT® measurement modules from CSM. It includes an EtherCAT® master and an XCP-on-Ethernet slave.

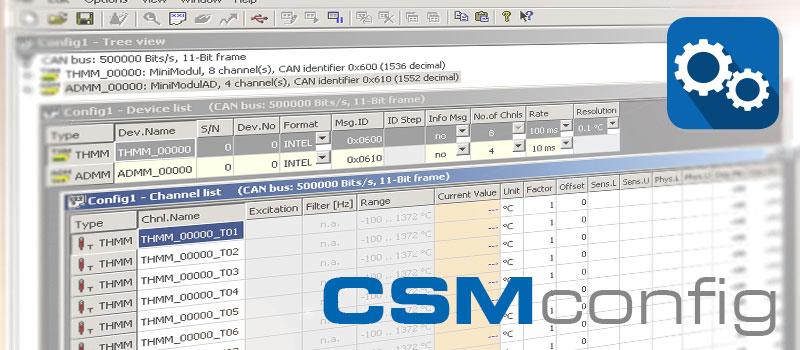

vMeasure, developed by Vector Informatik, is an easy-to-use software tool for the acquisition and analysis of measurement data that can be used in combination with all CAN- and EtherCAT®-based CSM measurement modules. CSMconfig was integrated directly to ensure swift configuration.

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.