Menu

- News

- Fields of Application

- Products

- Support

- Downloads

- Company

- Contact

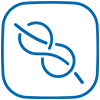

The high-voltage cables of the high-voltage vehicle electrical systems in modern electric vehicles are exposed to strong current and voltage ripples, which induce currents in the braided shields. If these shield currents exceed the capacity of the braided shield, cable fires and damage to connected accessories are the result. To ensure the safety of the system, extensive measurements of the shield currents are necessary.

High-voltage cables have an braided shield for safety and mitigation of electromagnetic interference. Large current and voltage ripples, which can occur due to high-frequency switching power electronics, determine the curve and the level of these shield currents. The length and diameter of the cables can further increase the effects. If the braided shield is not sufficiently dimensioned, cable fires can be caused due to the high temperature of the cables and cable glands on housings, and damage the entire system.

Measurement task

Measurement of currents in the braided shield to ensure that the capacity of the shield is not exceeded.

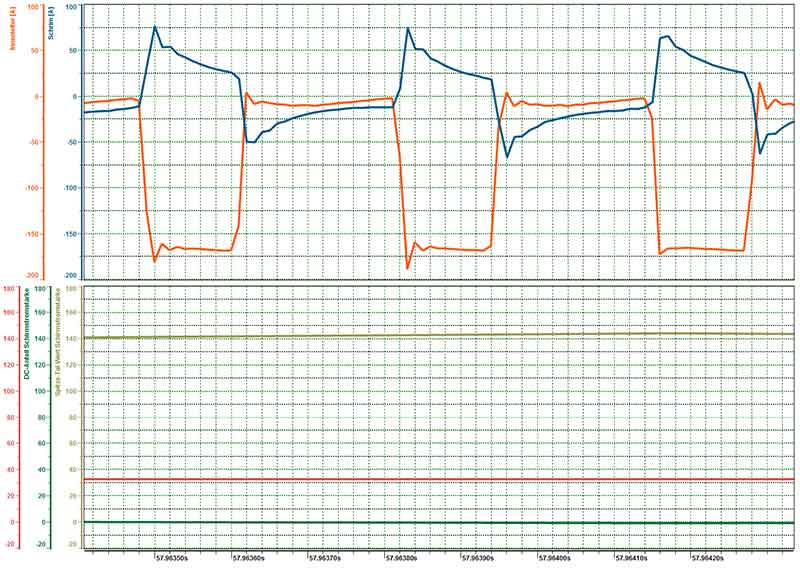

Shield currents must be measured in all cables of the high-voltage vehicle electrical system, which means that a large number of measurement points is required. The measurement data must be recorded synchronously at a high sampling rate of 1 MS/s. This is the only way to acquire current peaks and analyse the effects of different load conditions on all areas of the system. Another challenge is the actual application of the shield current measurement, as the braided shield must be separated from the inner conductor and a low-resistance connection must be established between the measurement technology and the braided shield. In addition, high-voltage safety must be ensured, as voltages continue to be applied to the inner conductor during the measurement. At the same time, temperatures on the cables and screwed connections should be measured in order to be able to make statements about the stress on the power installation.

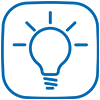

Thanks to special Breakout Modules for sield current measurement, shield currents can be acquired synchronously and at a high data rate at many points in the vehicle electrical system. Due to the robust design, testing is also possible in road tests and the high-voltage vehicle electrical system can be designed safely. The high-voltage safe CSM measurement modules ensure the safety of the user and the measured object during the measurement.

With the HV BM 1.2+S, other variables (current, voltage and power in the inner conductor) can be acquired synchronously with the measurement of the shield currents. This enables extensive analyses of the shield currents in different driving situations.

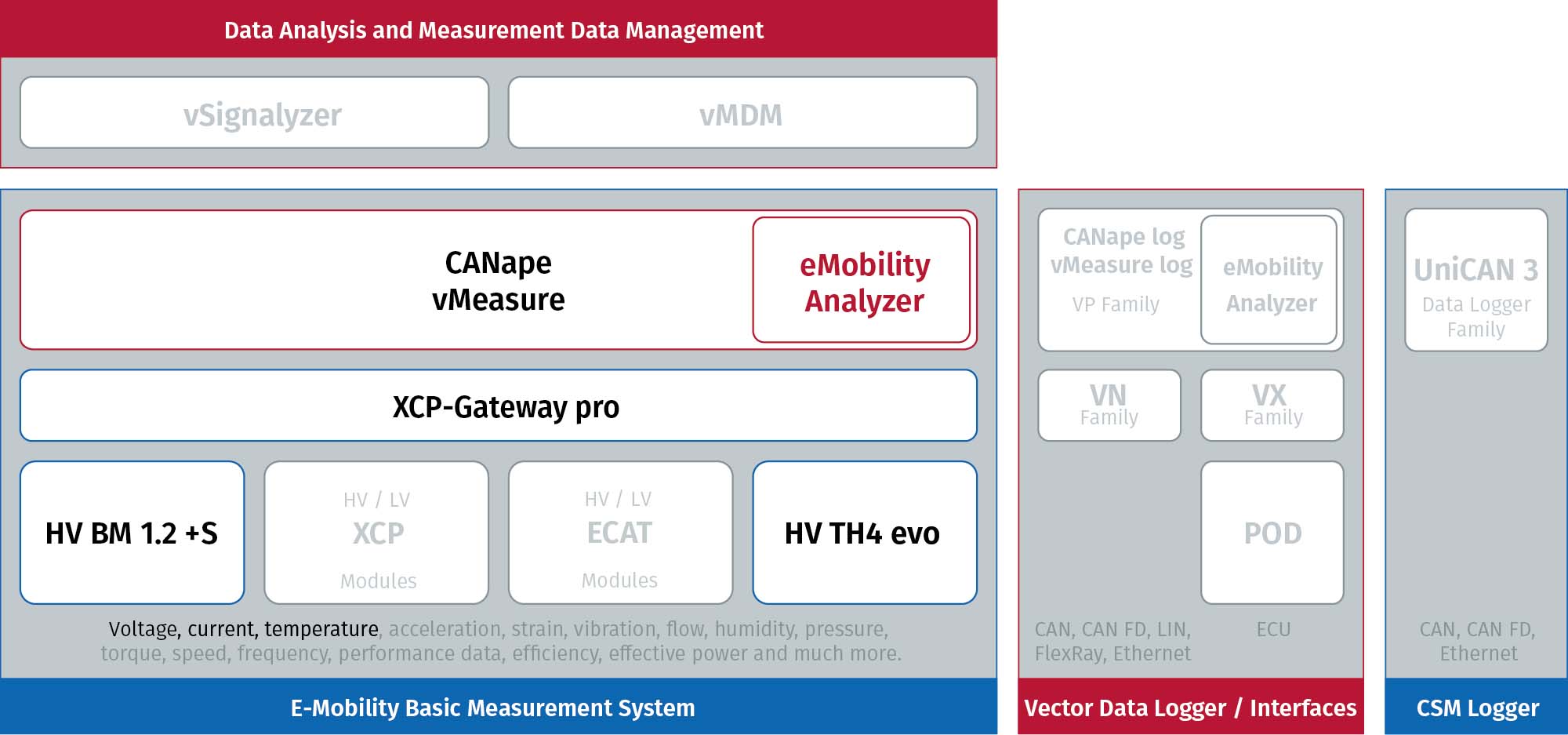

Due to the coordinated software and hardware, up to 40 measurement channels, each at 1 MHz, can be acquired simultaneously and synchronized with the Vector-CSM measurement system, in order to also carry out multi-channel, distributed vehicle applications. The Precision Time Protocol (PTP) ensures data synchronization in the measurement system.

Users can trigger on specific events or calculate other variables relevant to the test. Examples are current peaks or signal derivations to correlate certain events with other measured variables over time. The measurement system can be expanded with a Vector interface if the vehicle is to be calibrated with the analysis computer via the serial POD (Plug on Device) interface. Advantageous is that control unit measurement variables are recorded simultaneously with the measured values of the CSM modules.

Safe temperature measurements with thermocouples on high-voltage components: the high-voltage-safe temperature measurement modules are specifically designed for the reliable acquisition of temperatures in electric and hybrid vehicles.

XCP-Gateway is the interface between the data acquisition software (e. g. vMeasure, CANape®, INCA®, Vision® ...) and the EtherCAT® measurement modules from CSM. It includes an EtherCAT® master and an XCP-on-Ethernet slave.

The HV Breakout Module (BM) type 1.2+S is specially designed for single-phase measurements on HV voltage power cables. It is suitable to simultaneously measure power, inner conductor current, shield current and voltage.

vMeasure, developed by Vector Informatik, is an easy-to-use software tool for the acquisition and analysis of measurement data that can be used in combination with all CAN- and EtherCAT®-based CSM measurement modules. CSMconfig was integrated directly to ensure swift configuration.

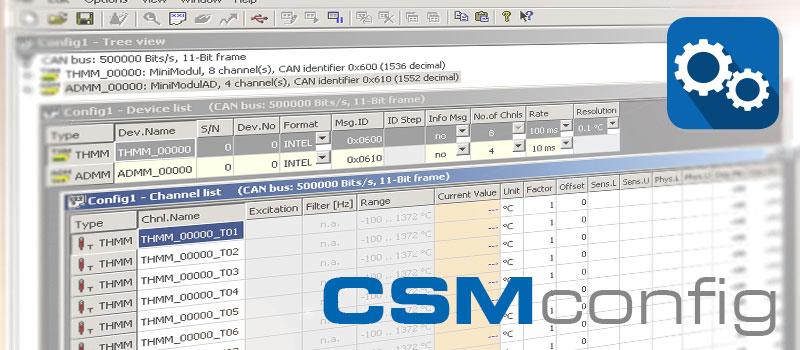

Swift configuration of measurement chains: CSMconfig is the reliable configuration software for all CAN and EtherCAT® based measurement modules from CSM. The clearly arranged and easy-to-use user interface allows an easy setting of all measurement parameters. This helps speeding up the measurement setup considerably.