Web Seminars

Menu

- News

- Fields of Application

- Products

- Support

- Downloads

- Company

- Contact

Web Seminars

Benchmarking plays a major role in vehicle development. Vehicle manufacturers want to understand how competitors solve problems - service providers want to offer comprehensive and objective data sets that enable precisely these comparisons. To obtain this data and the resulting insights, robust and flexible measurement systems are required that can be used, for example, to implement a large number of measurement points for a wide range of measured variables in production vehicles in confined spaces.

In this web seminar, we will show you in a compact 25 minutes:

Global competition, time pressure due to shortened development cycles and rising costs in the areas of materials, energy and staff - these are the challenges currently facing the automotive industry. To overcome them, a flexible and cost-efficient measurement system is needed that provides vehicle manufacturers, suppliers and engineering service providers with a tool for vehicle development of electric and hybrid vehicles of all kinds.

In this web seminar you will learn:

Analog measuring systems can be classified into two groups: On the one hand, decentralized measuring systems that can be positioned in confined spaces and operated under demanding environmental conditions. On the other hand, centralized measuring systems, which are less robust and larger in comparison, but offer a higher number of measuring inputs and often lower costs per channel.

The new VIO system from Vector Informatik is such a centralized measuring system. Thanks to its measurement card-based design, the measurement system can be easily scaled. By integrating network interface cards, the measurement task can be extended from purely measuring analog measurement values to bus monitoring and adjustment.

For the comprehensive analysis and testing of electric vehicles, physical parameters from numerous sources (HV and low-voltage environment) must be acquired and analyzed. A precise evaluation of the data is only possible through the synchronous acquisition of the data. In addition, the design of such a measurement system should be conceivably simple and precisely tailored to the measurement task.

Fuel cell drives require an extensive amount of testing and measurement during the development phase. This is because the combination of electrochemical components and power electronics places special requirements on the measurement technology.

In this webinar, we will take a close look at measurements on fuel cells and address the following questions:

When developing vehicle systems, engineers from development and validation often work on the same test vehicle. However, their working methods differ fundamentally. In development, the focus is on ad-hoc investigations with an interactive character. In validation on the other hand, preconfigured measurement jobs are recorded autonomously over several test drives. Up to now, different tools have been used: a computer-based measurement system and a specialized fleet logger. In practice, this always means set-up time - i.e. reconnecting when changing the mode of operation - and also doubled maintenance effort for the configurations.

Vector Smart Logger overcome these hurdles and offer a system that can be operated both interactively and autonomously. This significantly reduces setup time and configuration effort.

Beyond that, you benefit from a significantly higher range of functions compared to classic fleet loggers. Signals from vehicle ECUs and buses, radar, LIDAR, cameras, analog measurement technology as well as online calculations, e.g. of the eMobilityAnalyzer, can be recorded synchronously. Complex system interactions can be investigated holistically.

More information at www.vector.com

Find more videos about the Smart Logger in the Vector Youtube channel

vMDM (Vector Measurement Data Management) is the cloud solution for efficiently managing large amounts of data from development, test benches and drive tests.

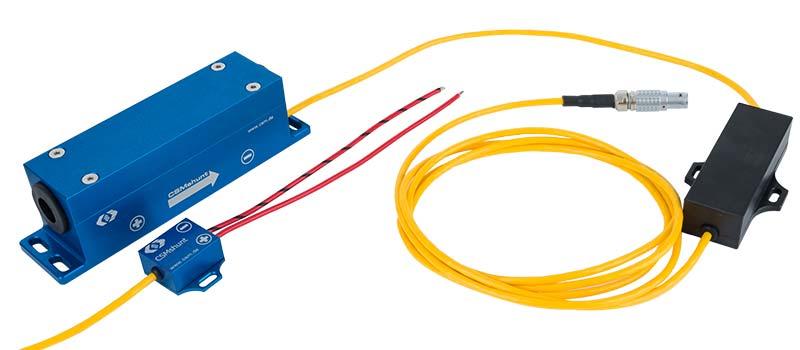

A comprehensive function library, precise algorithms for calculating characteristic variables, and modern cloud technologies enable fast and meaningful analysis of the variables in electrical components, drives, and vehicle electrical systems that are precisely and time-synchronously recorded using CSM measurement technology.